Foamed plastic-electrolytic manganese slag compound insulation block and preparation method thereof

A foamed plastic, electrolytic manganese slag technology, applied in building materials, climate change adaptation and other directions, can solve the problems of less than ideal thermal insulation effect, little electrolytic manganese slag, and inability to make good use of electrolytic manganese slag, etc., and achieves easy processing. Forming, high mechanical strength, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

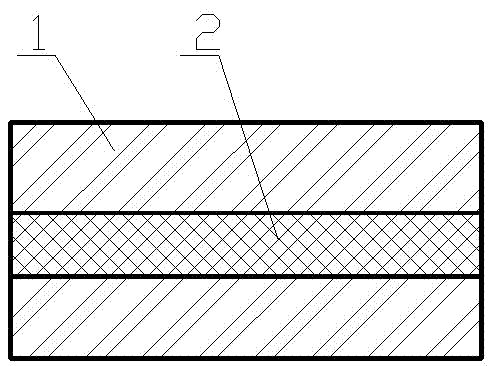

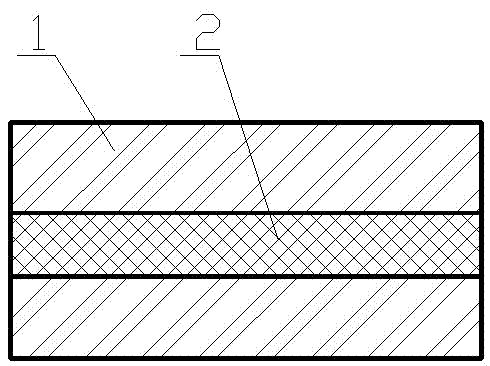

[0015] Embodiment 1: The structure of foamed plastics of the present invention and electrolytic manganese slag composite insulation block is as follows figure 1 As shown, the foamed plastic and electrolytic manganese slag composite thermal insulation block is composed of electrolytic manganese slag hollow block 1 and foam plastic core 2, and the hollow part of electrolytic manganese slag hollow block 1 is filled with foam plastic core 2; , first prepare the composite material of electrolytic manganese slag hollow block 1 according to the following method, take 20-40 parts of electrolytic manganese slag, 10-30 parts of cement, 20-50 parts of sand, and 0.5-1.8 parts of quicklime , gypsum 0.1~0.5 part, each raw material is water according to the ratio of water to material: the amount of material=0.45~0.85 is added water and mixes and promptly makes the composite material of electrolytic manganese slag hollow block 1; This composite material adopts traditional mold The electrolyti...

Embodiment 2

[0016] Embodiment 2: first make the composite material of electrolytic manganese slag hollow block 1 according to the mode of embodiment 1, then according to the hollow shape of the electrolytic manganese slag hollow block 1 to be made, first use XPS polystyrene foam board, EPS polystyrene Styrene foam board or polyurethane foam board to make a foam plastic core 2 with the same hollow shape as the electrolytic manganese slag hollow block 1, and put the formed foam plastic core 2 into the mold for pouring the electrolytic manganese slag hollow block 1 , and then pour the composite material of the prepared electrolytic manganese slag hollow block 1 into the mold, and make the composite material wrap the foam plastic core 2 and form it in the mold through traditional vibration, so that it can be obtained The foamed plastic and electrolytic manganese slag compound thermal insulation block of the present invention.

Embodiment 3

[0017] Embodiment 3: Produce the composite material of electrolytic manganese slag hollow block 1 according to the mode of embodiment 1, adopt the mode of traditional mold pouring to make electrolytic manganese slag hollow block 1 with this composite material, then adopt existing polystyrene Ethylene foam plastic or polyurethane foam plastic is the foam plastic raw material, and the foam plastic raw material is poured into the hollow of the electrolytic manganese slag hollow block 1 according to the traditional pouring method, so that it is foamed in the hollow part of the electrolytic manganese slag hollow block 1 It is formed into a foamed plastic core 2, so that the foamed plastic and electrolytic manganese slag composite thermal insulation block of the present invention can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com