Micro-energy system with high energy density per unit volume and fabrication method thereof

A technology of micro-energy and specific energy, applied in the field of microelectronics, can solve the problems of low volume energy density, etc., and achieve the effect of increasing volume specific energy density, saving space, and reducing external circuit connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

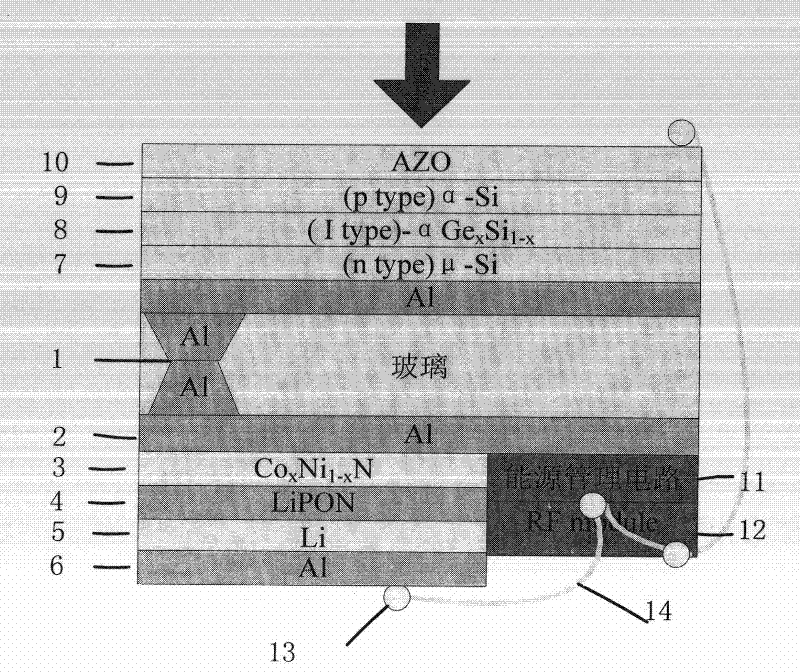

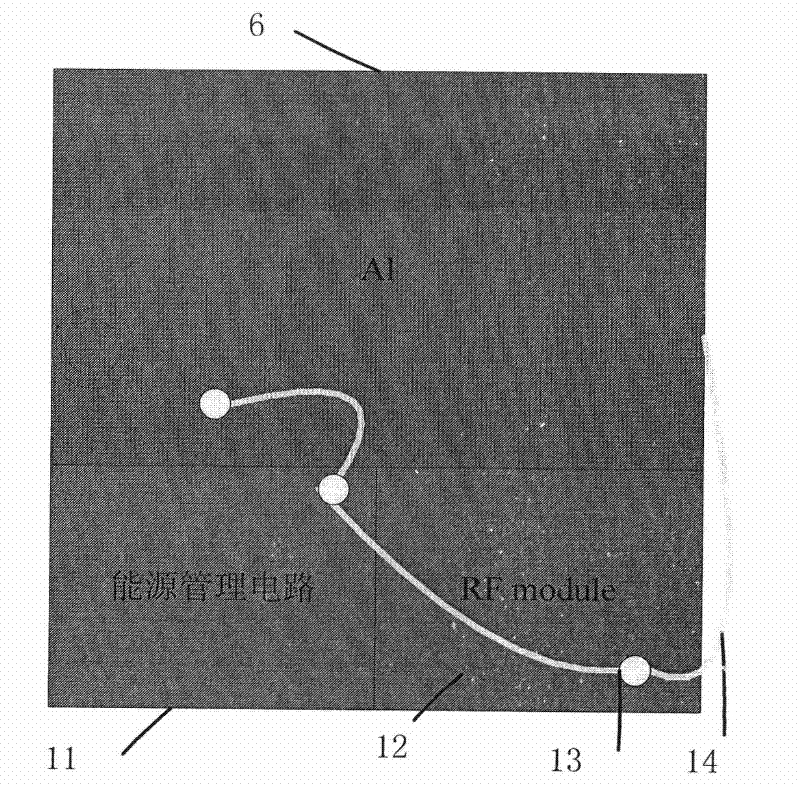

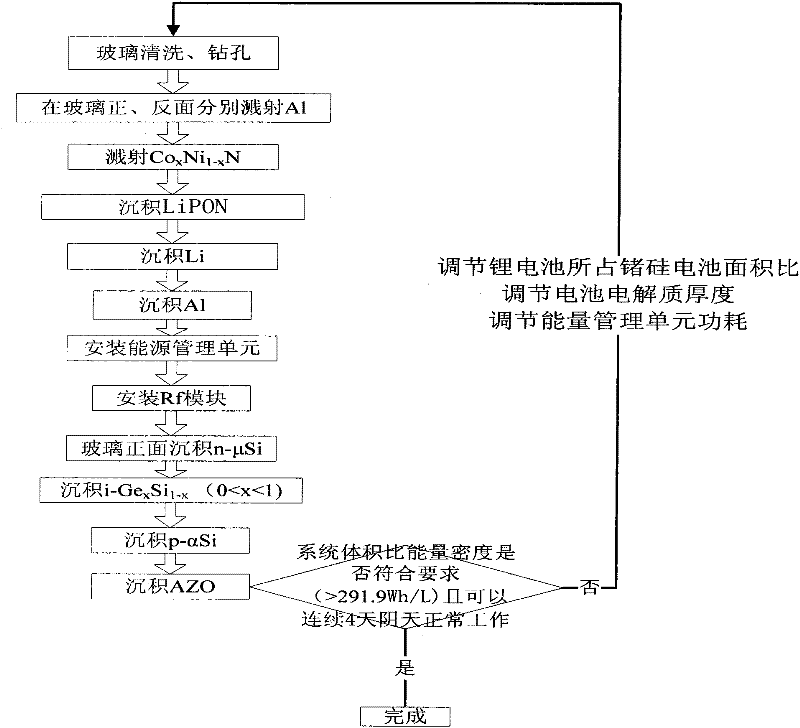

[0020] The manufacturing method of the high volume ratio energy density micro-energy system of the present invention, its manufacturing process (such as figure 2 )as follows:

[0021] 1. Drill holes on the glass substrate with a diamond drill, and the holes are two opposite hollow circular platforms (as shown in Figure 1).

[0022] 2. Al films are sputtered on the front and back of the glass respectively, and the Al thickness is enough to fill the depth of the cavity to realize double-sided Al interconnection;

[0023] 3. Deposit cobalt nickel nitride, LiPON film, Li film and Al film on the back of Al in sequence; sputter deposit Co on the Al surface x Ni 1-x N, 0-4 Below Pa, the substrate temperature is less than 80°C during deposition until the thickness of the nickel-cobalt nitride film is 900nm; the LiPON film is deposited by sputtering on the surface of the nickel-cobalt nitride film; the LiPON film manufacturing process is to make Li 3 PO 4 Target, using this target,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com