Processing method of sugar-free fruit and vegetable crushed dried pork

A processing method and the technology of vegetable floss are applied in the processing of meat floss, the processing of candy-free vegetable floss, and the field of making candy-free vegetable floss. Single effect of comfort and change of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

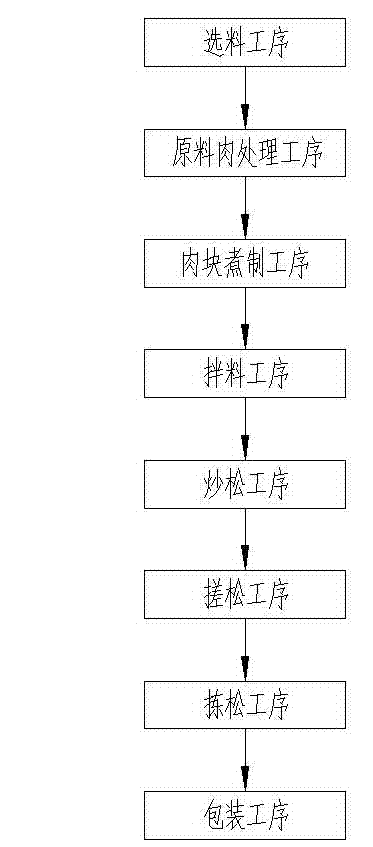

[0033] see figure 1 , the processing method of the candy-free vegetable and meat floss in the present embodiment sequentially comprises a material selection process, a raw meat processing process, a meat piece cooking process, a mixing process, a frying process, a loosening process, a loosening process and a packaging process.

[0034] (1) In the material selection process, select the required raw materials, which include raw meat 40-60kg, salt 1-1.5kg, fructooligosaccharide 9-12kg, I+G0.04-0.07kg, monosodium glutamate 0.6-0.8kg, monascus red pigment 0.002-0.004kg, iso-Vc sodium 0.2-0.6kg, fruit and vegetable powder 4-8kg and broth 5-20kg. For example, the raw meat in the present invention can be 40kg, 42kg, 44kg, 46kg, 48kg, 50kg, 52kg, 54kg, 56kg, 58kg or 60kg, and the salt can be 1kg, 1.1 ㎏, 1.2㎏, 1.3㎏, 1.4㎏ or 1.5kg, fructooligosaccharides can be 9㎏, 10kg, 10.5kg, 11kg, 11.5kg or 12kg, I+G can be 0.04kg, 0.05kg, 0.06kg Or 0.07kg, MSG can be 0.6kg, 0.65kg, 0.70kg, 0.75kg ...

Embodiment 2

[0051]Select 50 kg of fresh pork hind legs, trim and remove broken bones, cartilage, fat, skin, fascia and connective tissue before cutting. When cooking, add the mesh bag with shallots, ginger and spices before adding the meat pieces. Take out the pot when the meat is cooked and the muscle fibers are loose. Add 10 kg of broth, 9 kg of fructooligosaccharides, 1 kg of salt, 0.6 kg of monosodium glutamate, 0.04 kg of I+G, 0.002 kg of monascus red pigment and 0.2 kg of iso-Vc sodium according to the recipe, and mix with the cooked meat. Mix the ingredients, and keep pressing the meat with a spatula to loosen the muscle fibers. After the paste collection is completed, transfer the meat floss to the stir-frying machine for segmental frying. When frying the floss for the first time, the temperature is 160°C, adjust the speed, fry until the moisture content is 19%, and let it loosen. The product is placed in a dry environment with a temperature slightly higher than room temperature...

Embodiment 3

[0053] Select 52kg of fresh beef, trim and remove broken bones, cartilage, fat, skin, fascia and connective tissue before cutting. When cooking, add the mesh bag with shallots, ginger and spices before adding the meat pieces. Take out the pot when the meat is cooked and the muscle fibers are loose. According to the recipe, add 15 kg of broth, 10 kg of fructooligosaccharide, 1.1 kg of salt, 0.7 kg of monosodium glutamate, 0.04 kg of I+G, 0.002 kg of monascus red pigment and 0.25 kg of iso-Vc sodium, and mix with the cooked meat. Mix the ingredients, and keep pressing the meat with a spatula to loosen the muscle fibers. After the paste is collected, transfer the floss to the stir-frying machine for segmental frying. When frying the floss for the first time, the temperature is 160°C, adjust the speed, fry until the moisture content is 20%, and let it loosen. The product is placed in a dry environment with a temperature slightly higher than room temperature to make it homogenize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com