Production method of high-whiteness aluminum hydroxide

A production method, aluminum hydroxide technology, applied in the direction of alkali metal aluminate/aluminum oxide/aluminum hydroxide preparation, etc., can solve the problems of low whiteness of aluminum hydroxide, unstable product quality, etc., and achieve stable quality, easy Operation, the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

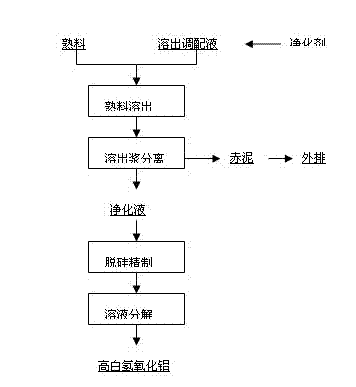

Image

Examples

Embodiment 1

[0021] After the bauxite is crushed, the ingredients are sintered at high temperature; the sintered product is added to the dissolution preparation solution (total alkali concentration N a2 o T :60g / L, alumina concentration Al 2 o 3 : 45g / L, carbonate alkali concentration N a2 o C :20g / L), wherein sodium sulfide is added to the dissolution preparation solution, and the amount of sodium sulfide added is 1Kg / m 3 . In the process of dissolving the alumina clinker, the preparation solution added with sodium sulfide reacts with heavy metal ions such as chromium and copper in the clinker to form precipitates, and the dissolution slurry is subjected to solid-liquid separation to purify the solution. After testing, the concentrations of chromium ions or copper ions in the purified solution are both less than 1.0ppm. The purified solution is desiliconized (to increase the A / S of the solution), and the desiliconized solution is decomposed to obtain high-white aluminum hydroxide. ...

Embodiment 2

[0025] After the bauxite is crushed, it is batched and sintered at high temperature; the sintered product is added to the dissolution preparation solution (total alkali concentration N a2 o T :60g / L, alumina concentration Al 2 o 3 : 45g / L, carbonate alkali concentration N a2 o C :20g / L), wherein sodium sulfide is added to the dissolution preparation solution, and the amount of sodium sulfide added is 5Kg / m 3 . In the process of dissolving the alumina clinker, the preparation solution added with sodium sulfide reacts with heavy metal ions such as chromium and copper in the clinker to form precipitates, and the dissolution slurry is subjected to solid-liquid separation to purify the solution. After testing, the concentrations of chromium ions or copper ions in the purified solution are both less than 1.0ppm. The purified solution is desiliconized (to increase the A / S of the solution), and the desiliconized solution is decomposed to obtain high-white aluminum hydroxide.

...

Embodiment 3

[0029] After the bauxite is crushed, the ingredients are sintered at high temperature; the sintered product is added to the dissolution preparation solution (total alkali concentration N a2 o T :60g / L, alumina concentration Al 2 o 3 : 45g / L, carbonate alkali concentration N a2 o C :20g / L), wherein sodium sulfide is added to the dissolution preparation solution, and the amount of sodium sulfide added is 0.1Kg / m 3 about. In the process of dissolving the alumina clinker, the preparation solution added with sodium sulfide reacts with heavy metal ions such as chromium and copper in the clinker to form precipitates, and the dissolution slurry is subjected to solid-liquid separation to purify the solution. After testing, the concentrations of chromium ions or copper ions in the purified solution are both less than 1.0ppm. The purified solution is desiliconized (to increase the A / S of the solution), and the desiliconized solution is decomposed to obtain high-white aluminum hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com