Machine-made sand light-expansion high early strength grouting material and preparation method thereof

A technology of machine-made sand and grouting materials, applied in the field of machine-made sand grouting materials, which can solve the problems of high sand price, unfavorable natural environment protection, and difficult control of production costs, and achieve high early strength, good economic and social benefits, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

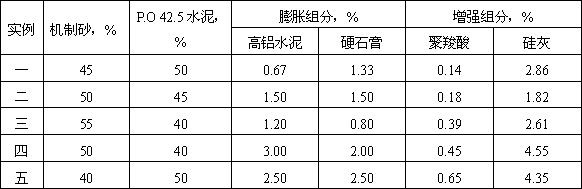

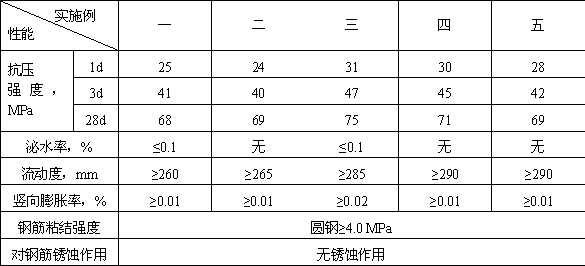

[0024] Embodiment one : A kind of machine-made sand micro-expansion high-early-strength grouting material and its preparation method

[0025] (1) Composition of raw materials: It is composed of the following raw materials in weight percentage, 45% of machine-made sand, 50% of ordinary Portland cement, 2% of expansion and shrinkage components, and 3% of reinforcement components. Among them, the expansion and shrinkage component is compounded by high alumina cement and anhydrite at a weight ratio of 0.5:1, and the reinforcing component is compounded by polycarboxylate superplasticizer dry powder and silica fume at a weight ratio of 0.05:1.

[0026] Raw material requirements:

[0027] Manufactured sand: MB value <1.4, stone powder content less than 5.0%, mud content less than 1.0%, moisture content less than 3%;

[0028] Ordinary Portland cement: the strength grade is 42.5, and the Blaine specific surface area is 350-400m 2 / Kg;

[0029] High alumina cement: the strength gra...

Embodiment 2

[0038] Embodiment two : the same place as embodiment one is no longer described, and the difference is:

[0039] Raw material composition: machine-made sand 50%, ordinary portland cement 45%, expansion and shrinkage component 3%, reinforcement component 2%. The weight ratio of high alumina cement to anhydrite in the expansion and shrinkage component is 1:1; the weight ratio of polycarboxylate superplasticizer dry powder to silica fume in the reinforcement component is 0.1:1.

[0040] Preparation method: the primary dry mixing time is 15 minutes, and the secondary dry mixing time is 15 minutes.

Embodiment 3

[0041] Embodiment three : the same place as embodiment one is no longer described, and the difference is:

[0042] Raw material composition: 55% machine-made sand, 40% ordinary Portland cement, 2% expansion and shrinkage components, and 3% reinforcement components. The weight ratio of the expansion and shrinkage component high alumina cement to anhydrite is 1.5:1; the weight ratio of the reinforcing component polycarboxylate superplasticizer dry powder to silica fume is 0.15:1.

[0043] Preparation method: the primary dry mixing time is 10 minutes, and the secondary dry mixing time is 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com