Technology for post-treating cyanacetate

A cyanoacetate and process technology, which is applied in the post-treatment process field of industrial methyl cyanoacetate or ethyl cyanoacetate, can solve problems such as difficult rectification and separation of malonate diester impurities, and achieve high removal rate, The effect of simple equipment structure and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

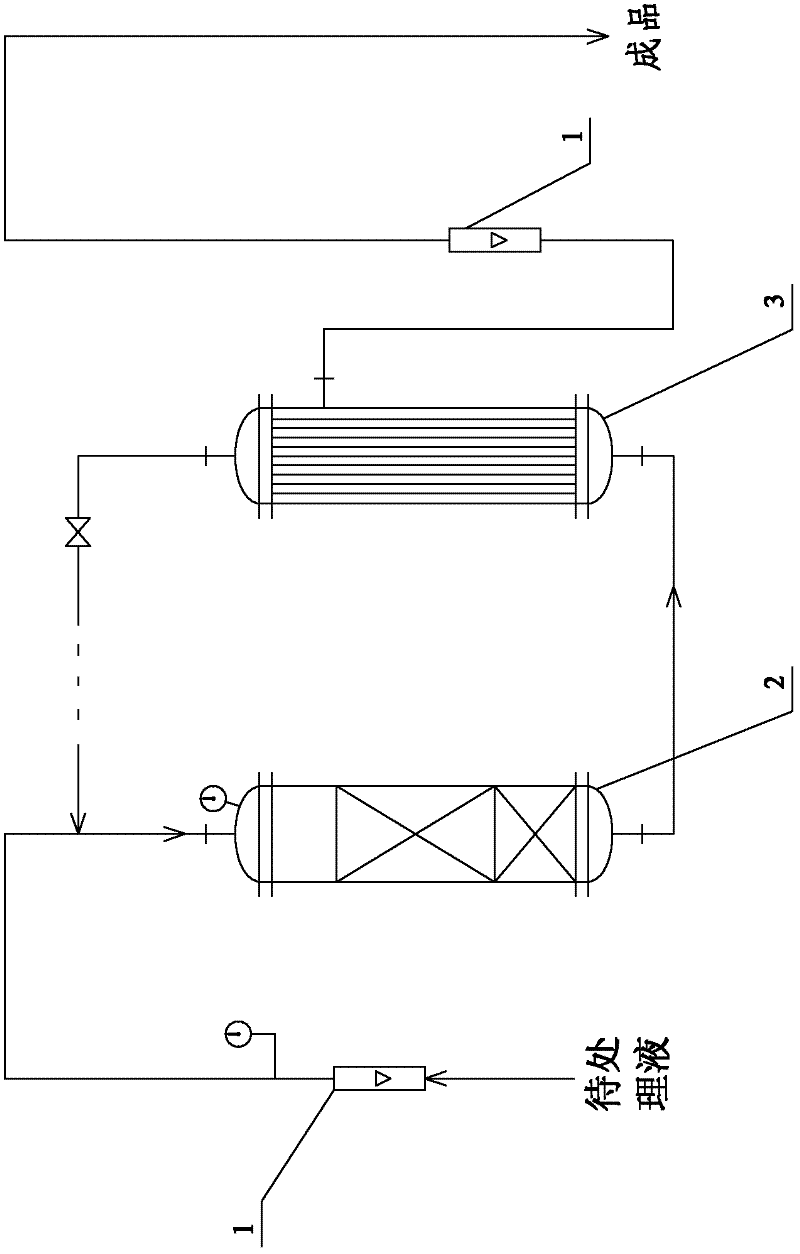

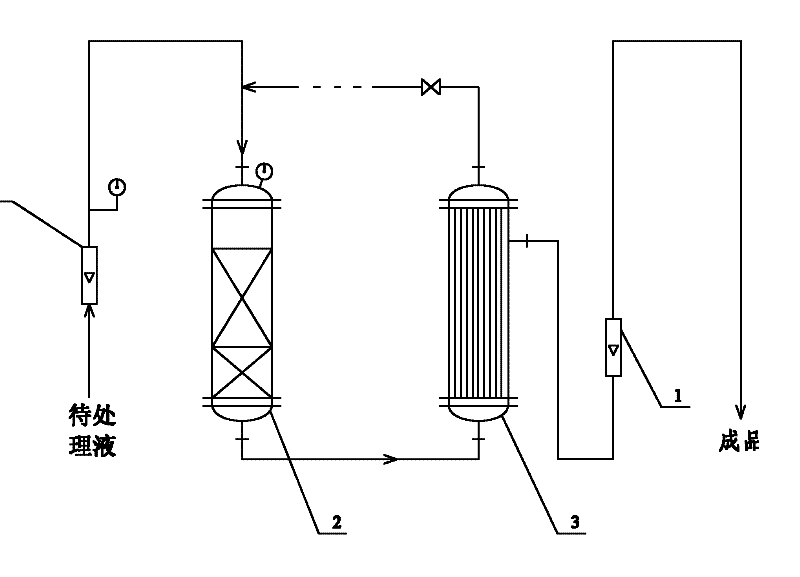

Image

Examples

Embodiment 1

[0017] A treatment tower with a diameter of 200mm and a length of 2000mm. There is a PE sintered tube with a length of 300mm and a precision of 5μ in the tower body. After the filter medium, there is a ceramic membrane fine outlet filter. The treatment medium component is 50% Na 2 CO 3 , 20% CaO and 30% cation exchange resin; the components of methyl cyanoacetate liquid to be treated are 99.2% methyl cyanoacetate, 20ppm cyanide, 0.08% dimethyl malonate, 0.12% moisture, and 0.1% acidity ;The liquid to be treated enters the tower body from the inlet, passes through the treatment medium layer, filter medium layer and ceramic membrane fine outlet filter, and flows out from the outlet; the treatment flow rate is 1.0-1.5m 3 / h; the obtained finished product components are 99.4% of methyl cyanoacetate, cyanide<2ppm, 0.03% of dimethyl malonate, 0.01% of moisture, and 0.02% of acidity.

Embodiment 2

[0019] A treatment tower with a diameter of 100mm and a length of 1500mm. The filter medium layer is a microporous filter membrane, the precision of the filter medium is 0.142μ; the treatment medium component is 70% K 2 CO 3 , 10% CaO and 20% cation exchange resin; the components of methyl cyanoacetate liquid to be treated are 99.2% methyl cyanoacetate, 20ppm cyanide, 0.15% dimethyl malonate, 0.06% moisture, and 0.2% acidity ;The liquid to be treated enters the tower body from the inlet, passes through the treatment medium layer and the filter medium layer, and flows out from the outlet; the treatment flow rate is 0.150-0.200m 3 / h; the finished product components obtained after recycling treatment are 99.4% of methyl cyanoacetate, cyanide<2ppm, 0.05% of dimethyl malonate, 0.008% of moisture, and 0.02% of acidity.

Embodiment 3

[0021] A treatment tower with a diameter of 100mm and a length of 1500mm, the filter medium layer is a microporous filter membrane, the precision of the filter medium is 0.142μ; the treatment medium component is 70% K 2 CO 3 , 10% CaO and 20% cation exchange resin; the components of ethyl cyanoacetate liquid to be treated are 98.5% ethyl cyanoacetate, 20ppm cyanide, 0.80% diethyl malonate, 0.05% moisture, and 0.2% acidity ;The processing flow is 0.150-0.200m 3 / h; the liquid to be treated enters the tower body from the inlet, passes through the treatment medium layer and the filter medium layer, and flows out from the outlet; the finished product components obtained are ethyl cyanoacetate 98.7%, cyanide<2ppm, diethyl malonate 0.50 %, moisture 0.07%, acidity 0.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com