Beta crystal polypropylene tensile expandable material and preparation method thereof

A technology of polypropylene material and tensile expansion, applied in the field of polypropylene material and its preparation, can solve the problems of low strength, complex preparation technology of tensile expansion material, reduction of material mechanical strength, etc., and achieve high shear modulus, resistance Good notch and fracture resistance, excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

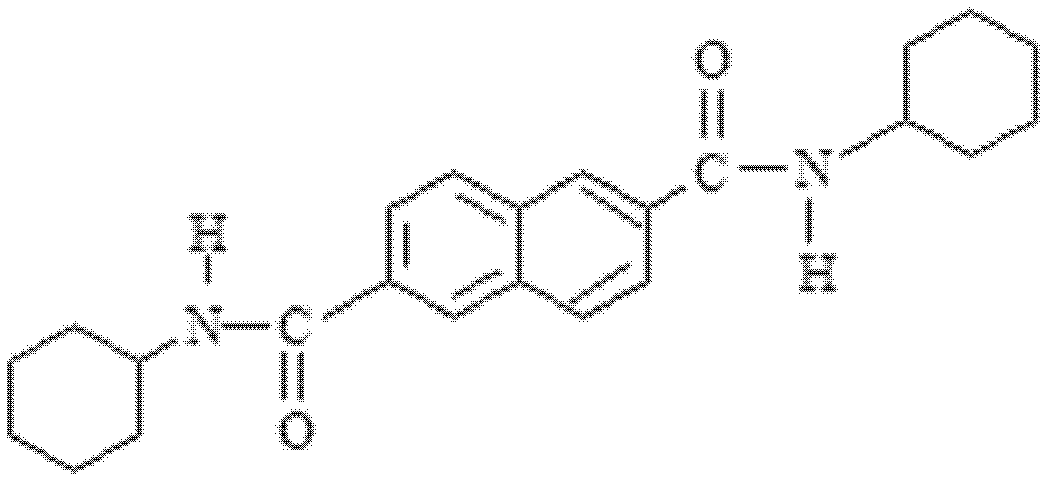

[0035] Take by weighing 100kg isotactic polypropylene (brand T1701), take by weighing DCNDCA nucleating agent 100g according to the amount of its mass percentage 0.1%, after the polypropylene and DCNDCA nucleating agent that weighed are mixed at a high speed at room temperature, send Put it into the feeding hopper of the twin-screw extrusion granulation unit, set the temperature of the mixing section of the unit to 210°C, and the temperature of the machine head to 190°C, and obtain polypropylene granules containing 0.1% by mass of DCNDCA nucleating agent through extrusion granulation , extrude the sheet after melting the pellets, control the crystallization temperature at room temperature (25° C.), and obtain a sheet product containing β crystals of polypropylene, and the sheet has tensile expansion properties.

[0036] The tensile performance test is carried out by using a micro-mechanical testing machine, which is the TST350 tensile hot table of Linkam Company. The data of S...

Embodiment 2

[0039] Take by weighing 50g of isotactic polypropylene (brand T1701), weigh 0.05g of DCNDCA nucleating agent according to its mass percentage of 0.1%, add the weighed polypropylene and DCNDCA nucleating agent to a banburying mixer set at 190°C In the internal mixing room, set the speed at 60rpm, stop the machine after 8 minutes and take out the material, hot press it at 190°C into a sheet, and then cool it to obtain a sample sheet containing β-crystal of polypropylene (the crystallization temperature is room temperature 20°C), which has a similar Figure 8 and Figure 9 The tensile expansion properties are described.

Embodiment 3

[0041] Take by weighing 50g isotactic polypropylene (brand T1701), weigh 0.5g of DCNDCA nucleating agent according to its mass percentage of 1%, and add the weighed polypropylene and DCNDCA nucleating agent to a banburying mixer set at 200°C In the internal mixing room, set the speed at 30rpm, stop the machine after 10min and take out the material, press it into a sheet at 200°C, and then cool it to obtain a sample sheet containing β crystal of polypropylene (the crystallization temperature is room temperature 20°C), which has a similar figure 2 and image 3 The tensile expansion properties are described.

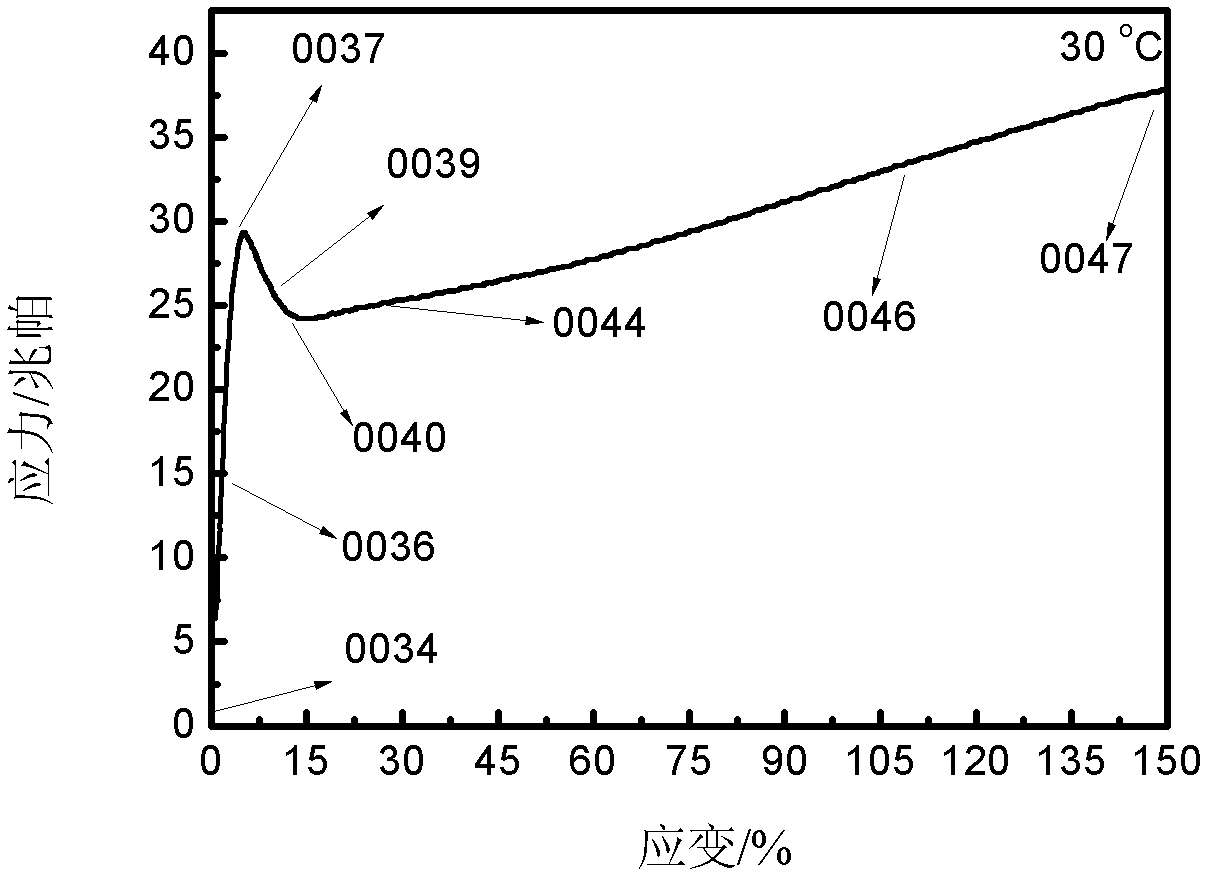

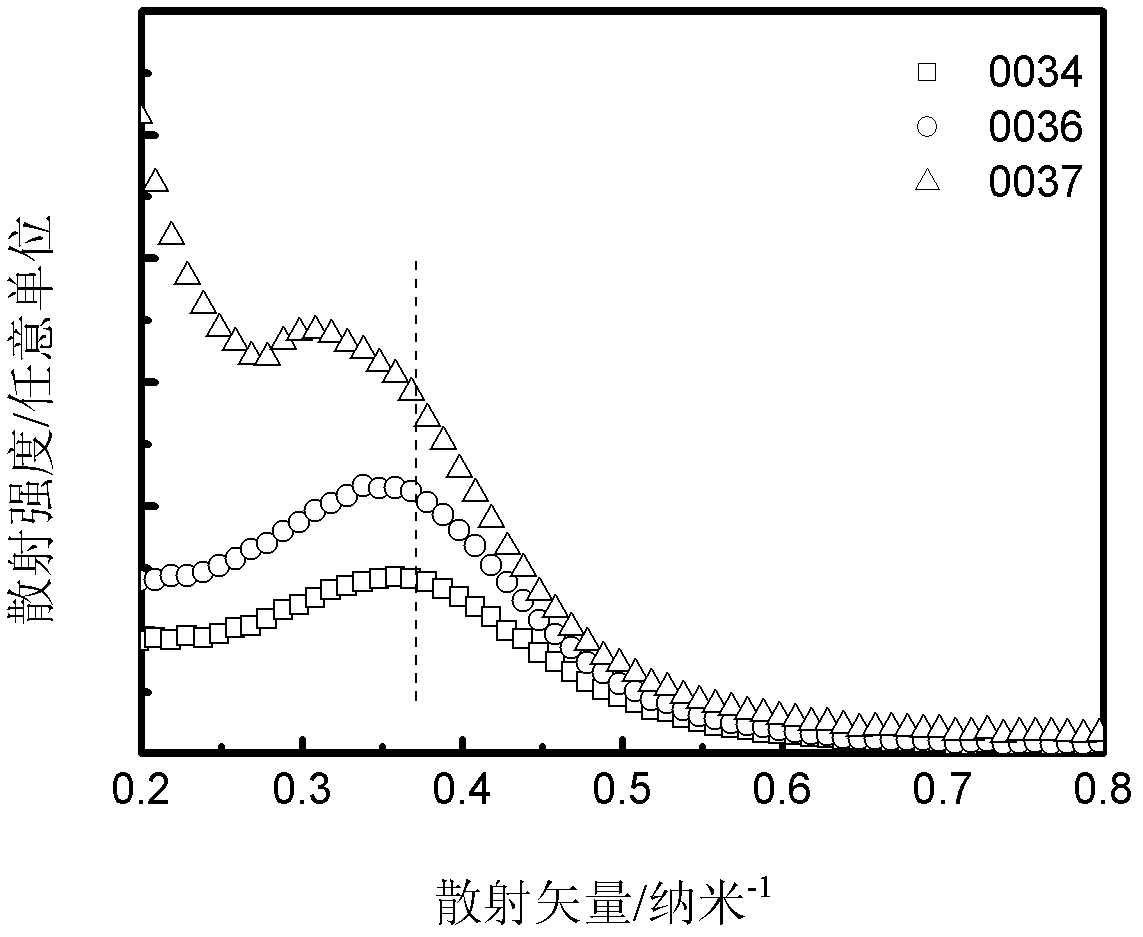

[0042] as attached figure 2 is the tensile stress-strain curve of polypropylene material containing β-crystal nucleating agent DCNDCA at 30°C, where 0034, 0036, and 0037 are marked as different tensile strain moments, and the materials corresponding to these different tensile strain moments are perpendicular to A SAXS plot in the stretching direction, such as image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com