High-activity cathode and preparation method thereof

A high-activity, cathode technology, applied in the direction of electrodes, electrode shapes/types, electrolytic components, etc., can solve the problems of easy generation of pores and unfavorable combination of coating layer and Ni matrix, so as to avoid pores and resist reverse current Enhanced impact and anti-poisoning ability, improved bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The nickel mesh was sandblasted in turn, and the nickel mesh was etched in a water bath at 50°C for 1 hour with a sulfuric acid solution with a mass fraction of 20%, cleaned by ultrasonic vibration in double-distilled water for 5 minutes, and dried in the air for later use. Apply the coating solution to the pre-treated Ni mesh substrate with a wool brush, and thermally decompose it to obtain a transition layer and an active layer.

[0041] The transition layer coating solution consists of:

[0042] Rhodium nitrate 1.5g / L

[0043] Concentrated nitric acid (mass fraction is about 65%) 2ml / L

[0044] Active layer coating solution consists of:

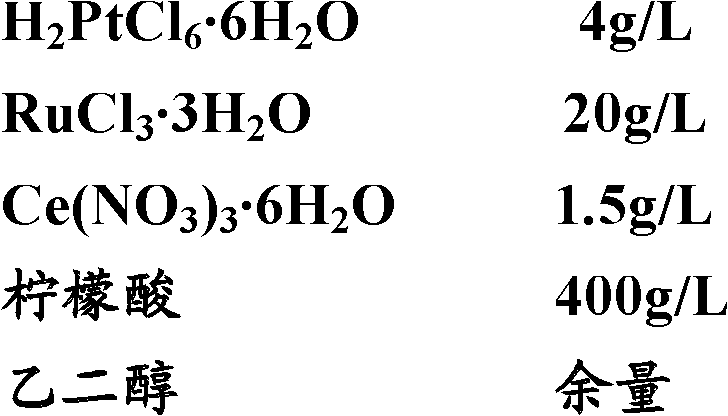

[0045]

[0046] Apply the coating solution of the transition layer to the Ni grid, dry at 160°C for 15 minutes, then put it into a high-temperature furnace, bake it at 500°C for 10 minutes, and cool to room temperature; repeat the above steps to make the Rh loading on the surface of the active cathode 0.1 g / m 2 .

[0047] Co...

Embodiment 2

[0051] The nickel mesh was sandblasted in turn, etched with 15% sulfuric acid solution in a water bath at 60°C for 1.5 hours, ultrasonically oscillated in twice distilled water for 5 minutes to clean it, and dried in the air for later use. Apply the coating solution to the pre-treated Ni mesh substrate with a wool brush, and thermally decompose it to obtain a transition layer and an active layer.

[0052] The transition layer coating solution consists of:

[0054] Concentrated nitric acid 2ml / L

[0055] Active layer coating solution consists of:

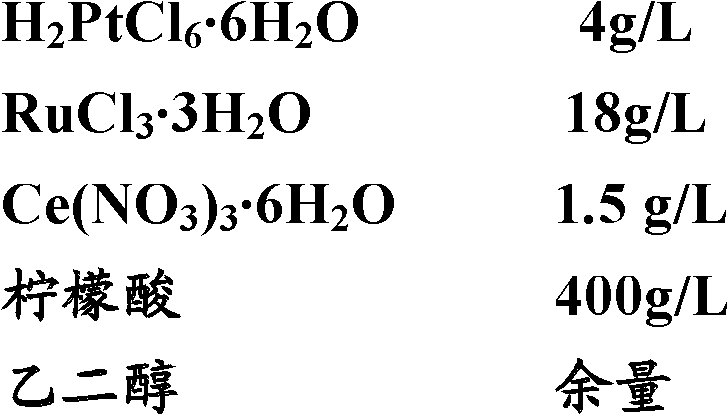

[0056]

[0057] Apply the coating solution of the transition layer to the Ni grid, dry at 150°C for 15 minutes, then put it into a high-temperature furnace, bake at 450°C for 15 minutes, and cool to room temperature; repeat the above steps to make the Rh loading on the surface of the active cathode 0.15 g / m 2 .

[0058] Coat the active layer coating solution on the Rh-coated Ni mesh substrate aft...

Embodiment 3

[0062] The nickel mesh was sandblasted in turn, etched with 25% sulfuric acid solution in a water bath at 80°C for 0.5 hours, cleaned by ultrasonic vibration in double-distilled water for 5 minutes, and dried in the air for later use. Apply the coating solution to the pre-treated Ni mesh substrate with a wool brush, and thermally decompose it to obtain a transition layer and an active layer.

[0063] The transition layer coating solution consists of:

[0065] Concentrated nitric acid 2ml / L

[0066] Active layer coating solution consists of:

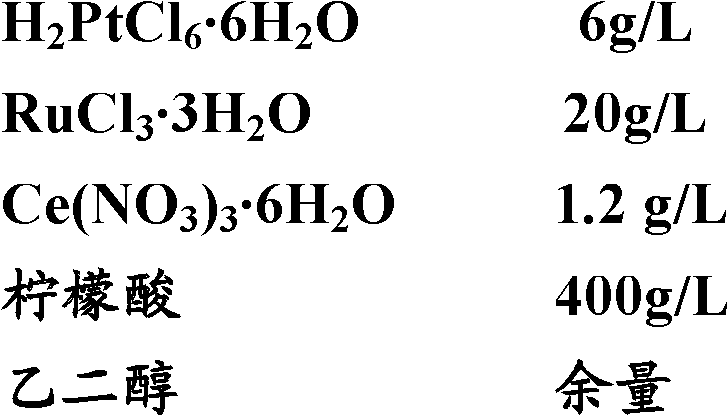

[0067]

[0068]

[0069] Apply the coating liquid of the transition layer to the Ni grid, dry it at 180°C for 10 minutes, then put it into a high-temperature furnace, bake it at 500°C for 10 minutes, and cool it to room temperature; repeat the above steps to make the Rh loading on the surface of the active cathode be 0.12g / m 2 .

[0070] Coat the active layer coating solution on the Rh-coated Ni me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com