Fluorescent sensor film preparation method based on perylene diimide cholesterol derivative

A perylene imide cholesterol and fluorescence sensing technology, applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve problems that cannot meet the needs of the society, and achieve simple operation, mild reaction conditions, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

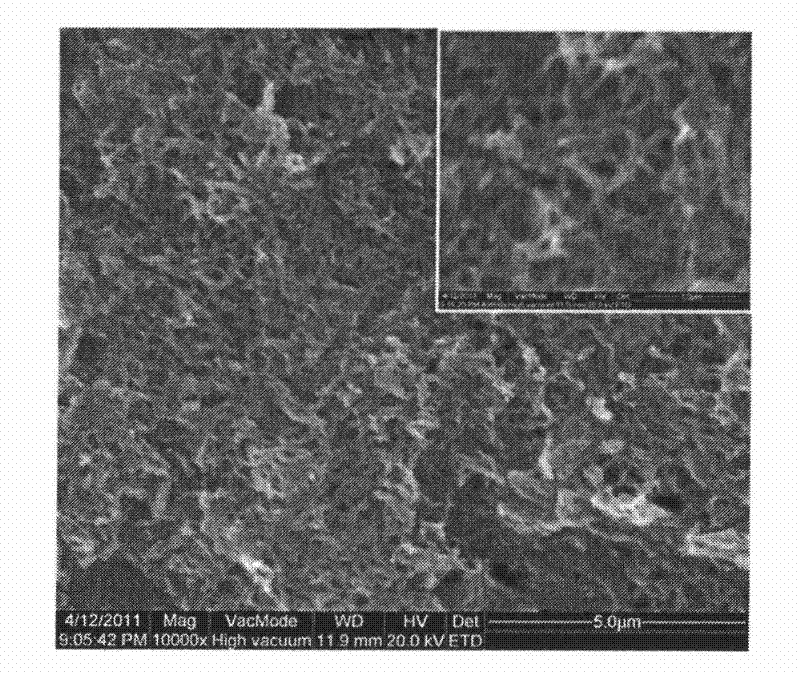

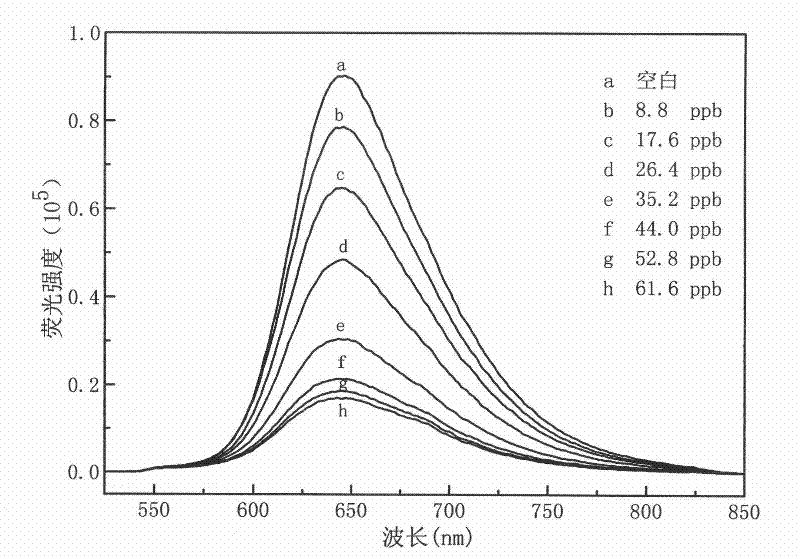

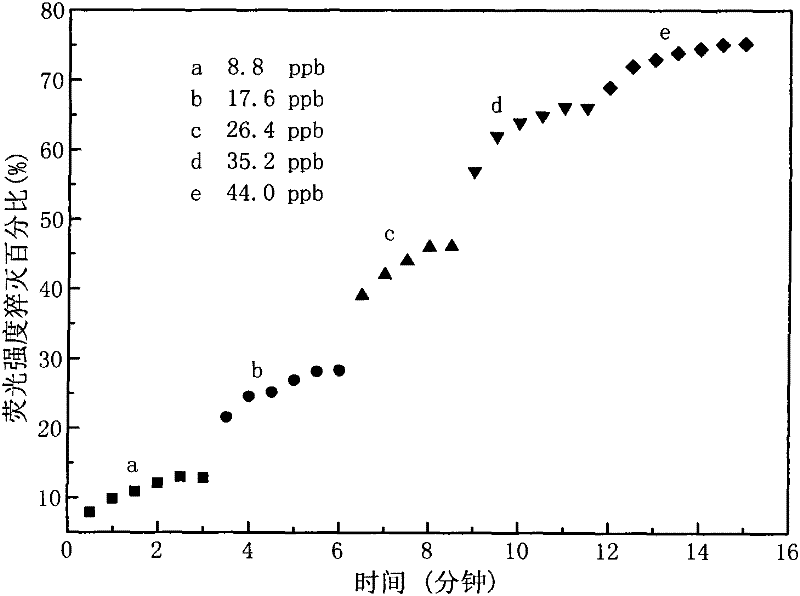

[0022] Taking the preparation of the peryleneimide cholesterol derivative fluorescent sensing film with propylenediamine as the connecting arm as an example, the preparation method is as follows:

[0023] 1. Synthetic formula I compound

[0024] Under the argon condition with a flow rate of 0.6-0.8mL / s, add 3g of propylenediamine to a 250mL three-necked flask filled with 130g of dichloromethane, and the mass ratio of propylenediamine to dichloromethane is 1:43; Get 0.9g of cholesterol chloroformate, dissolve it with 50mL of dichloromethane and drop it into a three-necked flask. The molar ratio of cholesterol chloroformate to propylenediamine is 1:20. Other steps and examples of this step 1, prepared as a compound of formula I, wherein the value of n is 3.

[0025] 2. Synthetic formula Ⅱ compound

[0026] Add 0.079g of perylene anhydride and 0.7g of the compound of formula I into a mixed solvent of propanol and distilled water, stir and reflux at 100°C for 15 hours under nitr...

Embodiment 2

[0031] Taking the preparation of hexamethylenediamine as an example of a peryleneimide cholesterol derivative fluorescent sensing film as a connecting arm, the preparation method is as follows:

[0032] In step 1 of the compound of formula I in Example 1, under an argon gas condition with a flow rate of 0.6 to 0.8 mL / s, 4.6 g of hexamethylenediamine was added to a 250 mL three-necked flask filled with 130 g of dichloromethane. The mass ratio of amine to dichloromethane is 1:28; weigh 0.9g of cholesterol chloroformate, dissolve it with 50mL of dichloromethane and drop it into a three-necked flask, the mole of cholesterol chloroformate and hexamethylenediamine The ratio is 1:20, and the other steps of this step are the same as in Example 1 to prepare a compound of formula I, where the value of n is 6. The other steps were the same as in Example 1, and a peryleneimide cholesterol derivative fluorescent sensing film was prepared with hexamethylenediamine as the connecting arm.

Embodiment 3

[0034] Taking the preparation of peryleneimide cholesterol derivative fluorescent sensing film with 12-carbon diamine as the connecting arm as an example, the preparation method is as follows:

[0035] In step 1 of the compound of formula I in Example 1, 20 g of 12 carbon diamines were added to a 250 mL three-necked flask containing 140 g of methylene chloride under an argon gas condition of 0.6 to 0.8 mL / s at a flow rate, and 12 The mass ratio of carbon diamine to dichloromethane is 1:7; weigh 0.9g of cholesterol chloroformate, dissolve it with 50mL of dichloromethane and drop it into a three-necked flask, and the cholesterol chloroformate and 12 carbon The molar ratio of the diamine is 1:20, and the other steps of this step are the same as in Example 1 to prepare the compound of formula I, wherein the value of n is 12. The other steps were the same as in Example 1, and a peryleneimide cholesterol derivative fluorescent sensing film was prepared with 12 carbon diamines as con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com