Composite electrode super capacitor and method for preparing same

A technology of supercapacitors and composite electrodes, applied in electrolytic capacitors, capacitors, capacitor electrodes, etc., can solve the problems of no obvious improvement in the performance of composite electrodes, inability to make full use of graphene, uneven mixing, etc., to achieve high energy density, production Low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

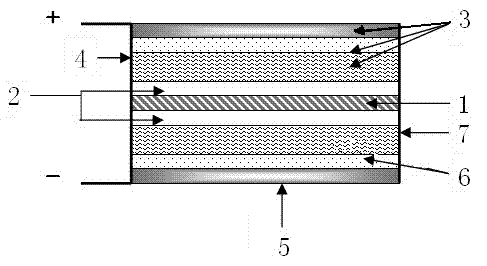

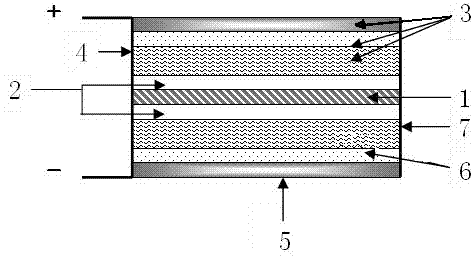

[0022] Embodiment 1 of the present invention: the structure of composite electrode supercapacitor is as figure 1 As shown, including diaphragm 1 and electrolyte 2, a porous polypropylene film is used as the diaphragm 1, and its thickness is 100 μm; sulfuric acid solution is used as the electrolyte 2; the electrolyte 2 is on both sides of the diaphragm 1, and a composite electrode is arranged on the outside of the electrolyte 2 3. The composite electrode 3 is composed of a collector electrode 5, a graphene layer 6 and a ruthenium dioxide layer 7. The graphene layer 6 covers the inner surface of the collector electrode 5, and the ruthenium dioxide layer 7 covers the inner surface of the graphene layer 6. On, the inner surface of the ruthenium dioxide layer 7 is in contact with the electrolyte 2; a sealant 4 is provided at both ends of the diaphragm 1, the electrolyte 2 and the composite electrode 3;

[0023] The preparation method of the composite electrode supercapacitor adopts...

Embodiment 2

[0024] Embodiment 2 of the present invention: the structure of composite electrode supercapacitor is as figure 1 As shown, including diaphragm 1 and electrolyte 2, a glass fiber porous film is used as the diaphragm 1 with a thickness of 8 μm; a hydrochloric acid solution is used as the electrolyte 2; the electrolyte 2 is located on both sides of the diaphragm 1, and a composite electrode 3 is provided on the outside of the electrolyte 2 , composite electrode 3 is made up of collector electrode 5, graphene layer 6 and ruthenium dioxide layer 7, and graphene layer 6 is covered on the inside surface of collector electrode 5, and ruthenium dioxide layer 7 is covered on the inside surface of graphene layer 6 , the inner surface of the ruthenium dioxide layer 7 is in contact with the electrolyte 2; a sealant 4 is provided at both ends of the diaphragm 1, the electrolyte 2 and the composite electrode 3;

[0025] The preparation method of composite electrode supercapacitor adopts copp...

Embodiment 3

[0026] Embodiment 3 of the present invention: the structure of composite electrode supercapacitor is as figure 1 As shown, including a diaphragm 1 and an electrolyte 2, nitric acid solution is used as the electrolyte 2, the electrolyte 2 is on both sides of the diaphragm 1, and a composite electrode 3 is provided on the outside of the electrolyte 2, and the composite electrode 3 is composed of a collector electrode 5, a graphene layer 6 and The ruthenium dioxide layer 7 is formed, the graphene layer 6 is covered on the inner surface of the collector electrode 5, the ruthenium dioxide layer 7 is covered on the inner surface of the graphene layer 6, and the inner surface of the ruthenium dioxide layer 7 is in contact with the electrolyte 2; A sealant 4 is provided at both ends of the diaphragm 1, the electrolyte 2 and the compound electrode 3; the diaphragm 1 is an ion-permeable membrane with a thickness of 200 μm.

[0027] The preparation method of the composite electrode superca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com