Tangent circle spiral spraying wet method smoke sulfur removal device

A wet flue gas desulfurization, tangential technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of large equipment construction, operation, maintenance, repair and other costs, and reduce the slurry circulation. times, enhanced mixing uniformity, and the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

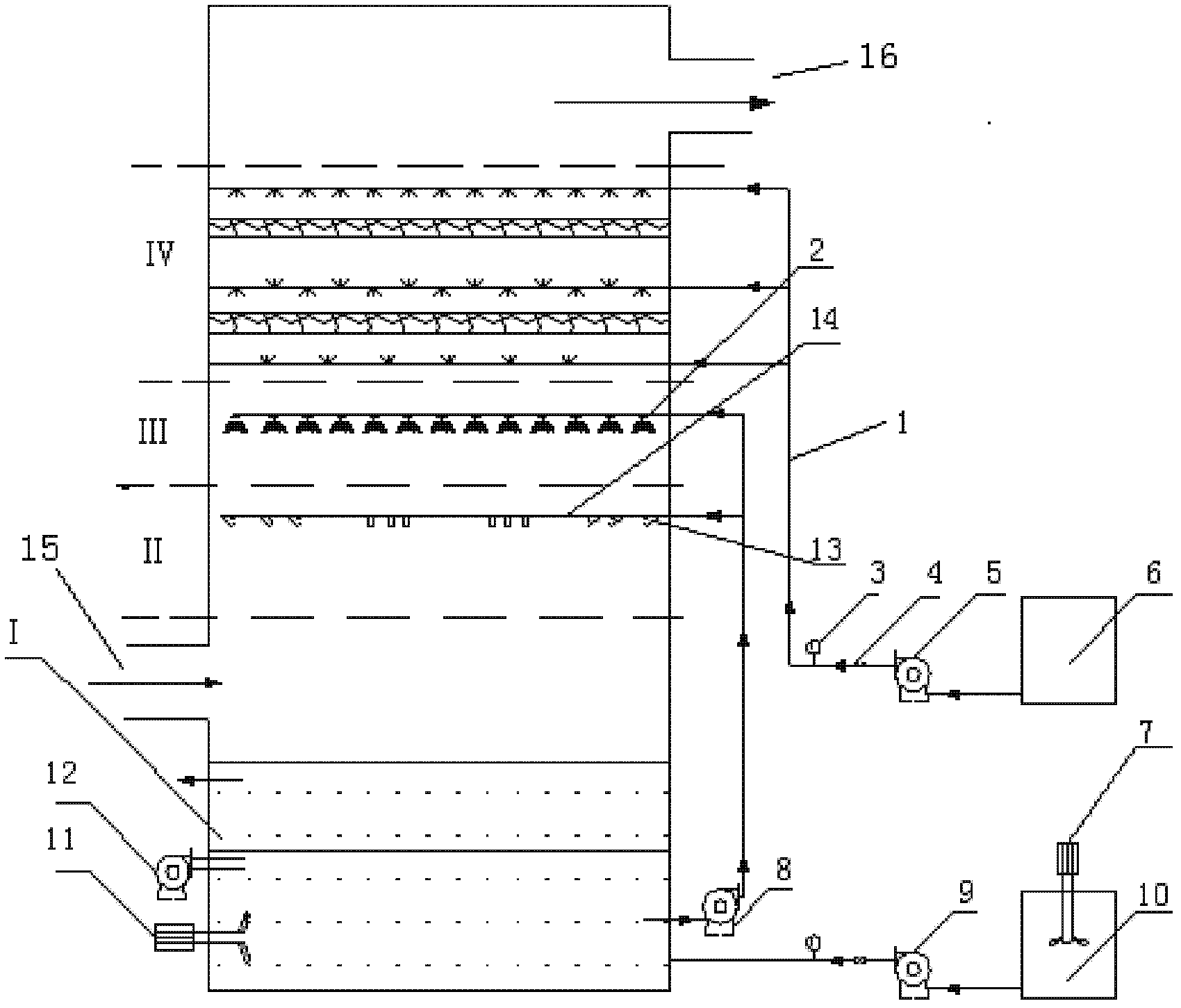

[0025] Such as figure 1 shown. The tangential spiral jet wet flue gas desulfurization device of the present invention includes an absorption tower, and the tangential spiral jet turbulent flow absorption layer II, conventional spray layer III and demisting layer IV are sequentially arranged in the absorption tower from bottom to top ; The tangential spiral jet turbulence absorbing layer II is composed of multiple groups of ultrasonic atomizing nozzles 13 arranged along the circular pipeline to punch and cut circles; the conventional spray layer III is composed of several mechanical nozzles arranged in arrays 2 composition;

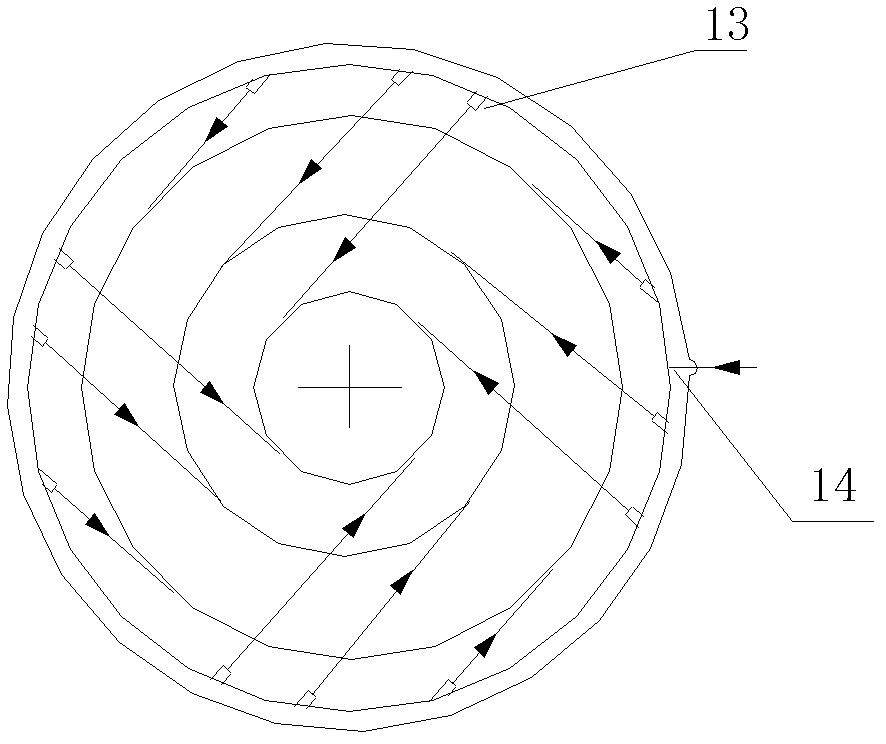

[0026] Such as figure 2 shown. The multiple sets of punching and tangential circle ultrasonic atomizing nozzles 13 arranged along the circular pipeline, wherein each group of punchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com