Composite black active dye

A reactive dye and black technology, which is applied in the field of composite black reactive dyes, can solve the problems of large difference in fiber affinity, large difference in hydrophilicity and lipophilicity, easy precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

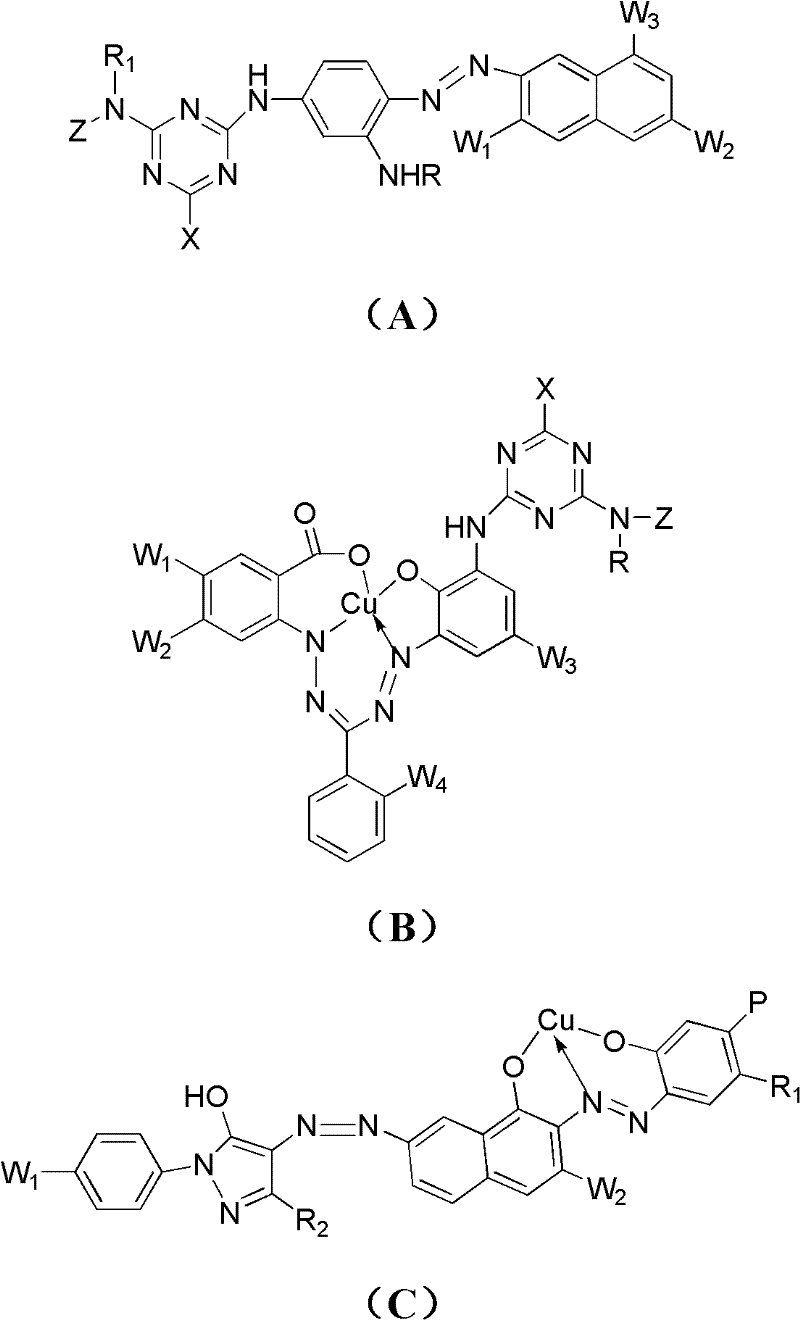

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

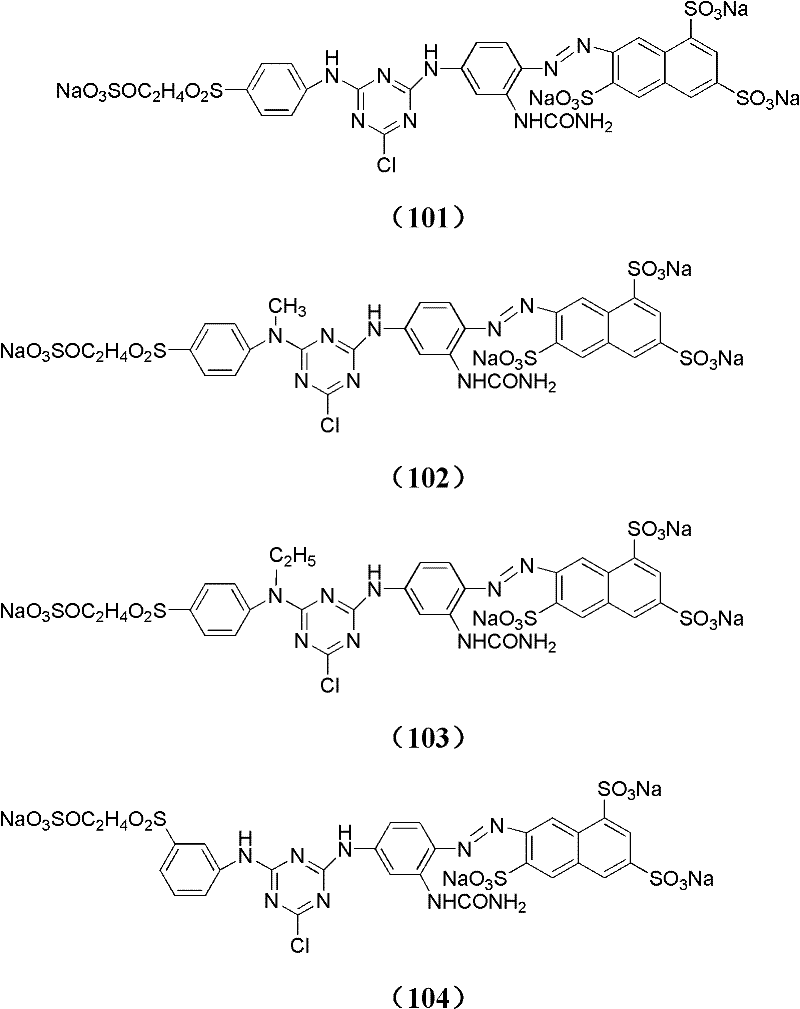

[0031] Step 1: Synthesis of Yellow Reactive Dye 101

[0032] Disperse 31.6g of K acid at a temperature of 10-12°C for 1 hour, then add hydrochloric acid and sodium nitrite as diazonium, and then conduct a coupling reaction with 10.4g of metaurea at a temperature of 10-15°C and maintain it with baking soda PH = 5.3-5.5, synthesize the chromophore, and then carry out a shrinkage reaction between the chromogen and 10g cyanuric chloride at a temperature of 0-5°C, and then add 16.5g para-ester for a double shrinkage reaction after the end point of the shrinkage reaction is reached. Temperature 41-43°C, use baking soda to maintain PH = 6.0-6.2, and keep the PH temperature for 8-10 hours to synthesize reactive dyes of formula (101), and spray all the obtained liquid to obtain about 77.8g of golden yellow dry product .

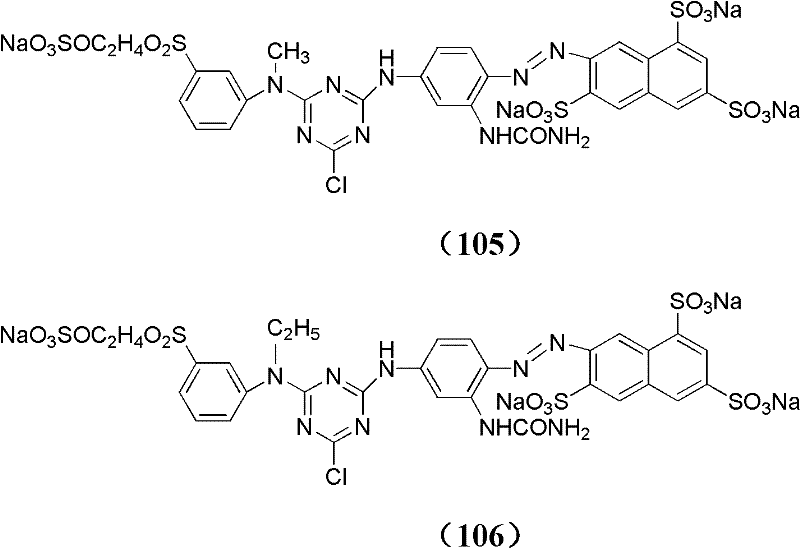

[0033] Step 2: Synthesis of blue reactive dye 201:

[0034] Put 36.9g of cyanuric chloride and 500g of ice water into the ice mill for beating, and add 56.2g of 3-β...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com