Holographic blazed grating manufacturing method

A technology of a blazed grating and a manufacturing method, which is applied in the field of preparation of diffractive optical elements, can solve problems such as difficulty in controlling the blaze angle, and achieve the effect of realizing the blaze angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

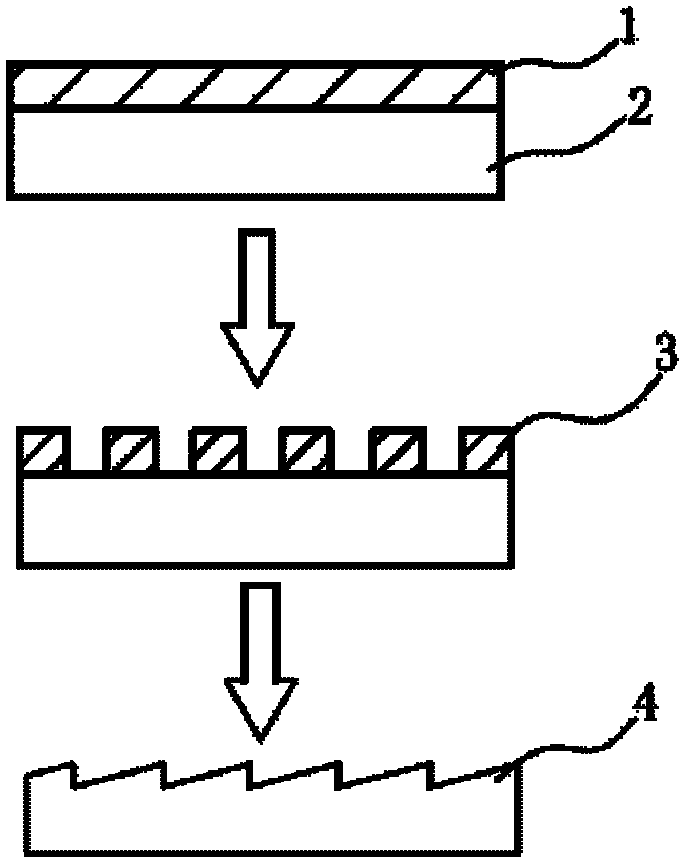

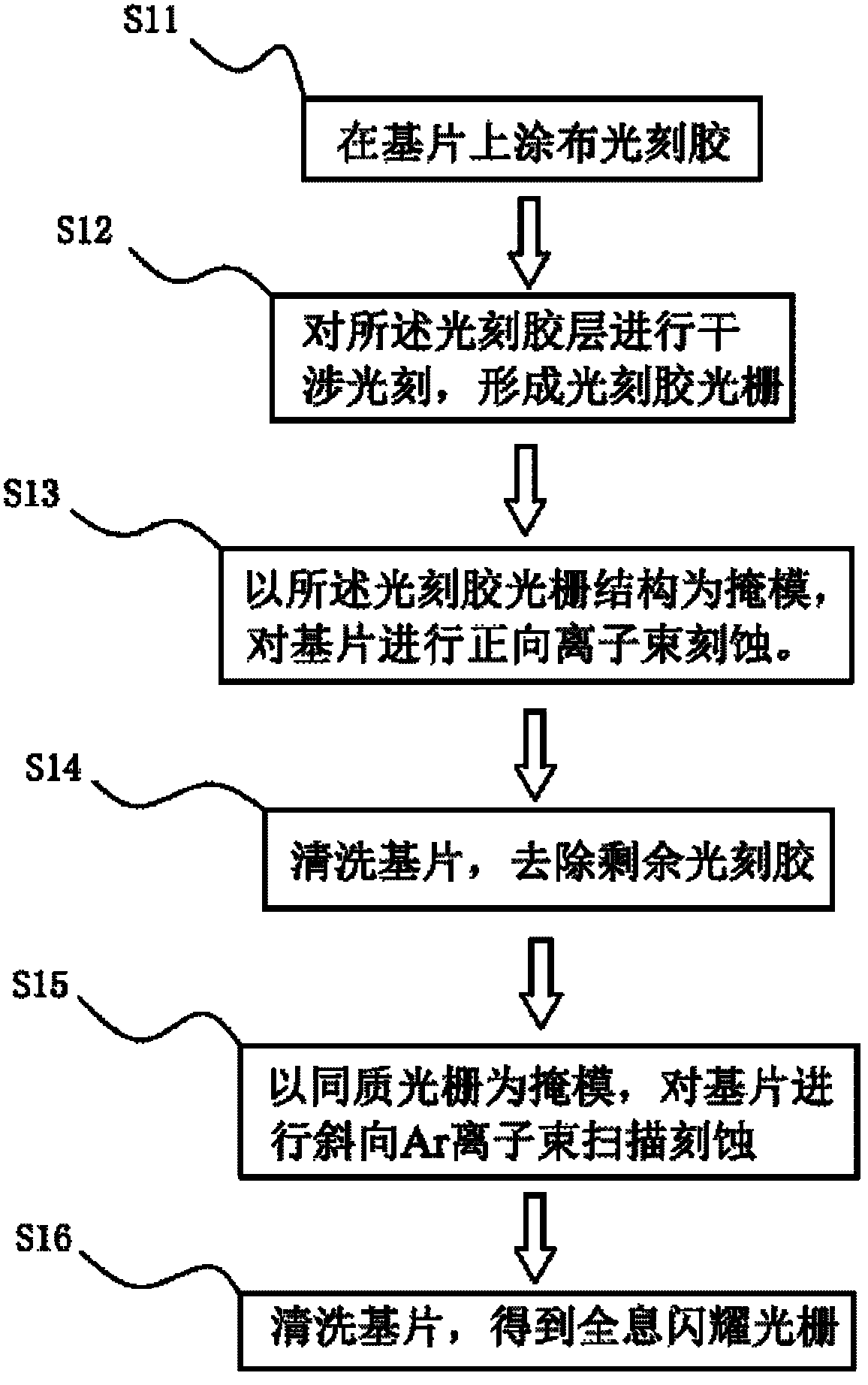

[0058] Example 1: Please refer to Figure 5 , Figure 5 It is a schematic diagram of the effects corresponding to each step in the first embodiment of the present invention. Fabricate a holographic blazed grating with a grating period of 833nm and a blaze angle θs of 10°, which is realized by interference exposure, forward ion beam etching and oblique Ar ion beam scanning etching. The homogeneous grating produced is a rectangular grating with a width of The ratio f=a / Λ=0.5. Include the following steps:

[0059] (1) Coating a photoresist 11 with a thickness of 300 nm on the quartz substrate 10 .

[0060] (2) Perform interference lithography to fabricate a photoresist grating mask 12 .

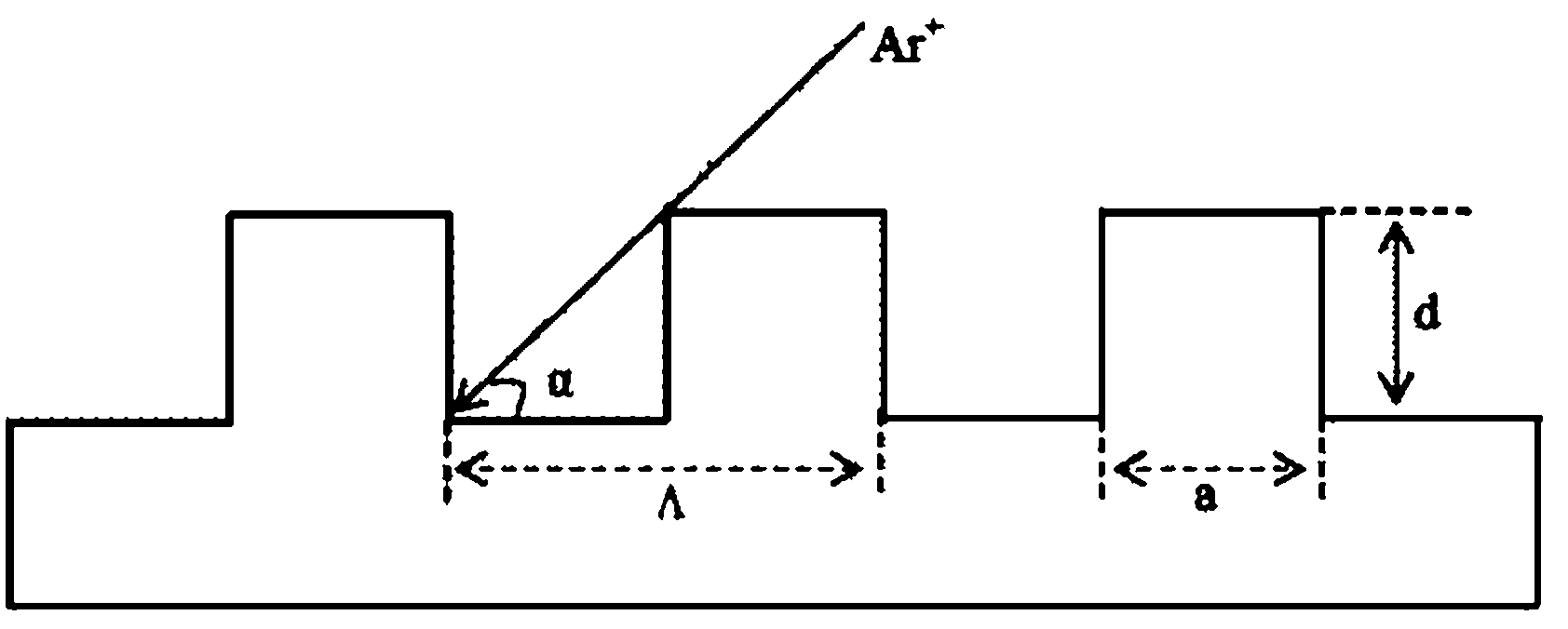

[0061] (3) Adopt rectangular grating (see image 3 ) as an example, first analyze the etching depth required to fabricate a blazed grating with a blaze angle θs of 10°. From the formula (2), the groove depth (d) of the homogeneous grating mask is 96nm. For this reason, the photoresist gra...

Embodiment 2

[0065] Example 2: Please refer to Figure 6 , Figure 6 It is a schematic diagram of the effects corresponding to each step in the second embodiment of the present invention. Fabricate a holographic blazed grating with a grating period of 833nm and a blaze angle θs of 15°, which is realized by interference exposure, forward ion beam etching, and oblique Ar ion beam scanning etching. The homogeneous grating is a rectangular grating with a width of The ratio f=a / Λ=0.35. Include the following steps:

[0066] (1) Coating a photoresist 21 with a thickness of 500 nm on the quartz substrate 20 .

[0067] (2) Perform interference lithography to fabricate a photoresist grating 22 .

[0068] (3) Perform an ashing process on the photoresist grating 22, adjust the duty ratio of the photoresist grating 22, and form a new photoresist grating 22'. The photoresist grating 22' can be transferred by forward ion beam etching to form a homogeneous grating with a duty ratio of 0.35 on the sub...

Embodiment 3

[0073] Example 3: Please refer to Figure 7 , Figure 7 It is a schematic diagram of the effects corresponding to each step in the third embodiment of the present invention. The method of making a holographic blazed grating with a grating period of 500nm and a blaze angle of 20° is realized by interference exposure, forward ion beam etching and oblique Ar ion beam scanning etching. The fabricated homogeneous grating is a trapezoidal grating with a trapezoidal angle β of 80° and a duty ratio of 0.5. Include the following steps:

[0074] (1) Coating a photoresist 31 with a thickness of 300 nm on the substrate 30 .

[0075] (2) Perform interference photolithography to fabricate a photoresist grating 32 . The groove shape of the photoresist grating here is different from the reaction time of the developer solution from top to bottom during development and etching, resulting in the upper photoresist being narrower than the lower photoresist, so that the groove shape of the phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com