Rare earth (RE) processed high strength high toughness corrosion resistant steel plate and preparation method thereof

A high-strength, high-toughness, corrosion-resistant steel plate technology, applied in the field of high-strength, high-toughness, corrosion-resistant steel plate, can solve problems that do not involve steel corrosion resistance, and achieve the effect of reducing C content, reducing alloy cost, and less alloying element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Smelt according to the chemical composition shown in Table 1, and cast into steel ingots, heat the steel ingots to 1220°C, keep them warm for 150 minutes, and carry out the first-stage rolling on the experimental rolling mill, the rolling temperature is 1170°C, at least 1-2 passes The secondary reduction rate is controlled at 20-40%. When the thickness of the rolled piece is 30mm, the temperature on the roller table is 920°C, and then the second stage of rolling is carried out. The final rolling temperature is 840°C, and the thickness of the finished steel plate is 12mm. After rolling, the steel plate enters the accelerated cooling (ACC) device and is cooled to 530°C at a rate of 25°C / s, and the cooling bed is cooled after the water exits.

Embodiment 2

[0031]The embodiment is the same as in Example 1, wherein the heating temperature is 1200° C., and the heat preservation is 150 minutes. The rolling start temperature of the first stage rolling is 1160° C., the thickness of the rolled piece is 36 mm, and the rolling start temperature of the second stage rolling is 910° C. The final rolling temperature is 830°C, the thickness of the finished steel plate is 12mm; the cooling rate of the steel plate is 25°C / s, and the final cooling temperature is 500°C.

Embodiment 3

[0033] The implementation is the same as in Example 1, wherein the heating temperature is 1200° C., and the heat preservation is 150 minutes; the rolling start temperature of the first stage rolling is 1150° C., and the thickness of the rolled piece is 36 mm; the rolling start temperature of the second stage rolling is 910° C., The final rolling temperature is 820°C, the thickness of the finished steel plate is 12mm; the cooling rate of the steel plate is 27°C / s, and the final cooling temperature is 480°C.

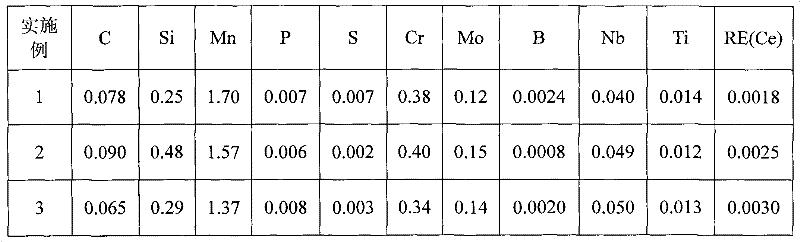

[0034] The chemical composition (wt %) of the embodiment of the present invention 1-3 of table 1

[0035]

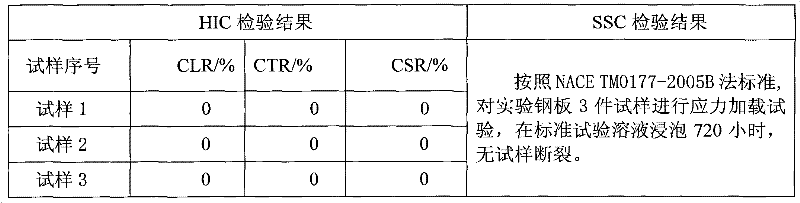

[0036] The steel plates of Examples 1-3 of the present invention were tested for mechanical properties, and the test results are shown in Table 2; the HIC and SSC test results are shown in Table 3.

[0037] The mechanical property of the steel plate of table 2 embodiment 1-3 of the present invention

[0038] Example

R p0.2 (MPa)

Rm(MPa)

A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com