Surface sizing agent and preparation method thereof

A technology of surface sizing agent and guar collagen, applied in the direction of water-repellent addition, etc., can solve the problems of production and environmental impact, slow reaction speed, reduce cationic starch, etc., achieve easy dispersion, increase affinity, and improve air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

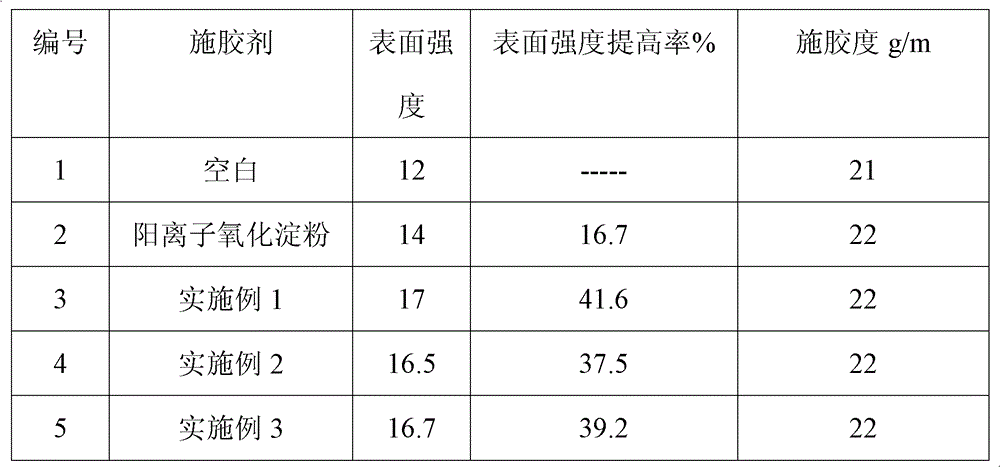

Examples

Embodiment 1

[0018] (1) Add 200 parts of ethanol to a four-necked flask equipped with stirring, thermometer, dripping pipeline and venting pipeline, blow nitrogen, add 200 parts of guar collagen powder under stirring, disperse at room temperature for 10 minutes, add dropwise Cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride 40 parts, the dropwise addition time is 15 minutes, after the dropwise addition, add sodium hydroxide solution, adjust the pH value of the solution to 11.0, heat up to 70°C, after two hours of reaction at this temperature, cationic guar gum is obtained, and the temperature of the system is lowered to 30°C;

[0019] (2) Use hydrochloric acid to adjust the pH value of the solution to 4.0, take 0.2 parts of peracetic acid and add it to the reaction kettle and mix it with cationic guar gum evenly, then heat up to 40°C and react for 2 hours;

[0020] (3) After the temperature of the above solution is lowered to 25°C, add 0.2 parts of viscosity ...

Embodiment 2

[0022] (1) Add 400 parts of ethanol to a four-necked flask equipped with stirring, thermometer, dripping pipeline and venting pipeline, pass nitrogen gas, add 200 parts of guar collagen powder under stirring, disperse at room temperature for 10 minutes, add dropwise Cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride 80 parts, dropwise time is 10 minutes, after the dropwise addition, add sodium hydroxide solution, adjust the pH value of the solution to 11.5, heat up to 60°C, after reacting at this temperature for three hours, cationic guar gum is obtained, and the system is cooled to 25°C;

[0023] (2) Use hydrochloric acid to adjust the pH value of the solution to 3.0, take 0.4 parts of peroxosulfuric acid and add it to the reaction kettle and mix it with cationic guar gum evenly, then heat up to 50°C and react for 1.5 hours;

[0024] (3) After reducing the temperature of the above solution to 25°C, add 0.4 parts of the viscosity stabilizer dicarb...

Embodiment 3

[0026] (1) Add 300 parts of ethanol to a four-necked flask equipped with stirring, thermometer, dripping pipeline and venting pipeline, pass nitrogen gas, add 200 parts of guar collagen powder under stirring, disperse at room temperature for 10 minutes, add dropwise 70 parts of cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride, the time of dropping is 15 minutes, after the dropwise addition is completed, adding a sodium hydroxide solution with a weight concentration of 30% to adjust the pH of the solution The value is 10.5, heat up to 55°C, and react at this temperature for 3.5 hours to obtain cationic guar gum, and cool the system to 30°C;

[0027] (2) Use hydrochloric acid to adjust the pH value of the solution to 4.0, take 2 parts of peracetic acid and add it to the reaction kettle and mix it with cationic guar gum evenly, then heat up to 70°C and react for 0.5 hours;

[0028] (3) After the temperature of the above solution is lowered to 25°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com