Application of rice hull carbon to preparation of brake pad and friction material of brake pad

A technology of friction materials and brake pads, applied in a new application field of rice husk charcoal, can solve problems such as pollution and waste of resources, and achieve the effects of large market supply, stable braking, and stable friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Mineral fiber 15%, graphite 10%, barium sulfate 22%, steel wool 17%, grinding agent 2%, coke powder 15%, tire powder 2%, resin 7%, nitrile powder 1%, calcium oxide 1%, Friction powder 3%, rice husk charcoal 5%, total 100%.

[0023] The above-mentioned materials were made into brake pads according to the conventional pressing method, and tested according to category 4 on a constant speed testing machine according to the GB5763-2008 standard. The results are shown in Table 1.

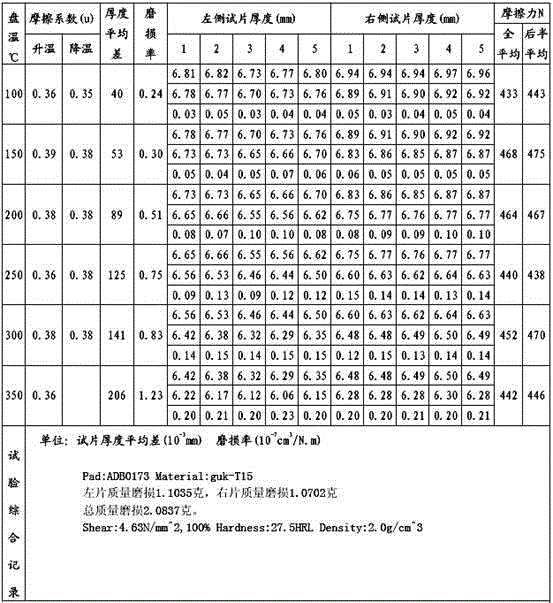

[0024] Table 1:

[0025]

[0026] It can be seen from the data in Table 1 that the brake pad obtained in Example 1 of the present invention has a friction coefficient of 0.36-0.48 in the heating stage, and a friction coefficient of 0.37-0.53 in the cooling stage, and the wear rate is small, which fully meets the national standard. After extensive use in Santana, Sonata and Jetta taxis, the braking is smooth, the braking noise is small, and the life of the friction material has reached more than...

Embodiment 2

[0028] Mineral fiber 15%, graphite 5%, barium sulfate 20%, steel wool 17%, grinding agent 2%, coke powder 10%, tire powder 2%, resin 9%, nitrile powder 1%, calcium oxide 1%, Friction powder 3%, rice husk charcoal 15%, total 100%.

[0029] The above materials were made into brake pads according to the conventional pressing method, and tested according to category 4 on a constant speed testing machine according to the GB5763-2008 standard. The results are shown in Table 2.

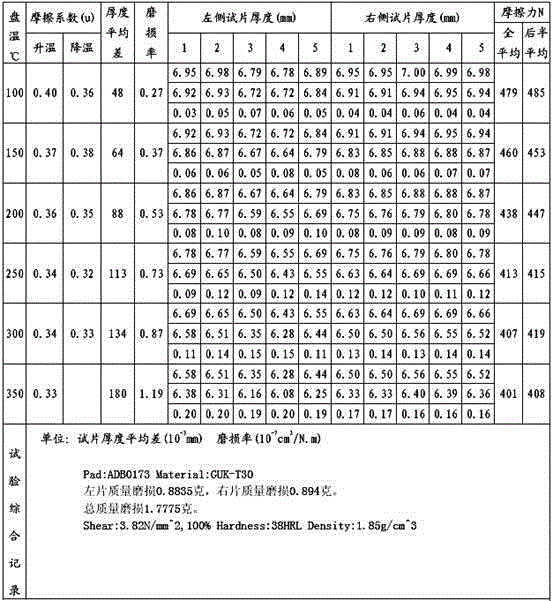

[0030] Table 2:

[0031]

[0032] It can be seen from the data in Table 2 that the brake pad obtained in Example 2 of the present invention has a friction coefficient of 0.36-0.39 in the heating stage, and a friction coefficient of 0.35-0.38 in the cooling stage, and the wear rate is small, which fully meets the national standard. After extensive use in Santana, Sonata and Jetta taxis, the braking is smooth, the braking noise is small, and the life of the friction material has reached more than 35,000 ki...

Embodiment 3

[0034] 10% mineral fiber, 5% graphite, 15% barium sulfate, 15% steel wool, 2% grinding agent, 5% coke powder, 2% tire powder, 11% resin, 1% nitrile powder, 1% calcium oxide, Friction powder 3%, rice husk charcoal 30%, total 100%.

[0035] The above materials were made into brake pads according to the conventional pressing method, and tested according to category 4 on a constant speed testing machine according to the GB5763-2008 standard. The results are shown in Table 3.

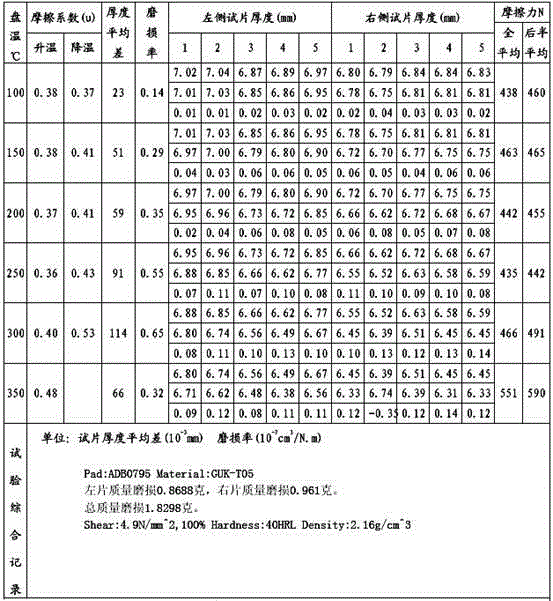

[0036] table 3:

[0037]

[0038] It can be seen from the data in Table 3 that the brake pad obtained in Example 3 of the present invention has a friction coefficient of 0.33-0.40 in the heating stage and a friction coefficient of 0.32-0.38 in the cooling stage, and the wear rate is small, which fully meets the national standard. After extensive use in Santana, Sonata and Jetta taxis, the braking is smooth, the braking noise is small, and the life of the friction material has reached more than 35,000 kil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com