High-frequency high-voltage X-ray defect detector

A high-frequency high-voltage flaw detection machine technology, applied in X-ray equipment, material analysis using wave/particle radiation, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve the problem of low voltage output of transformers, Affect the performance of the flaw detector, energy release and consumption, etc., to achieve the effect of reduced size, stable work, and small potential difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

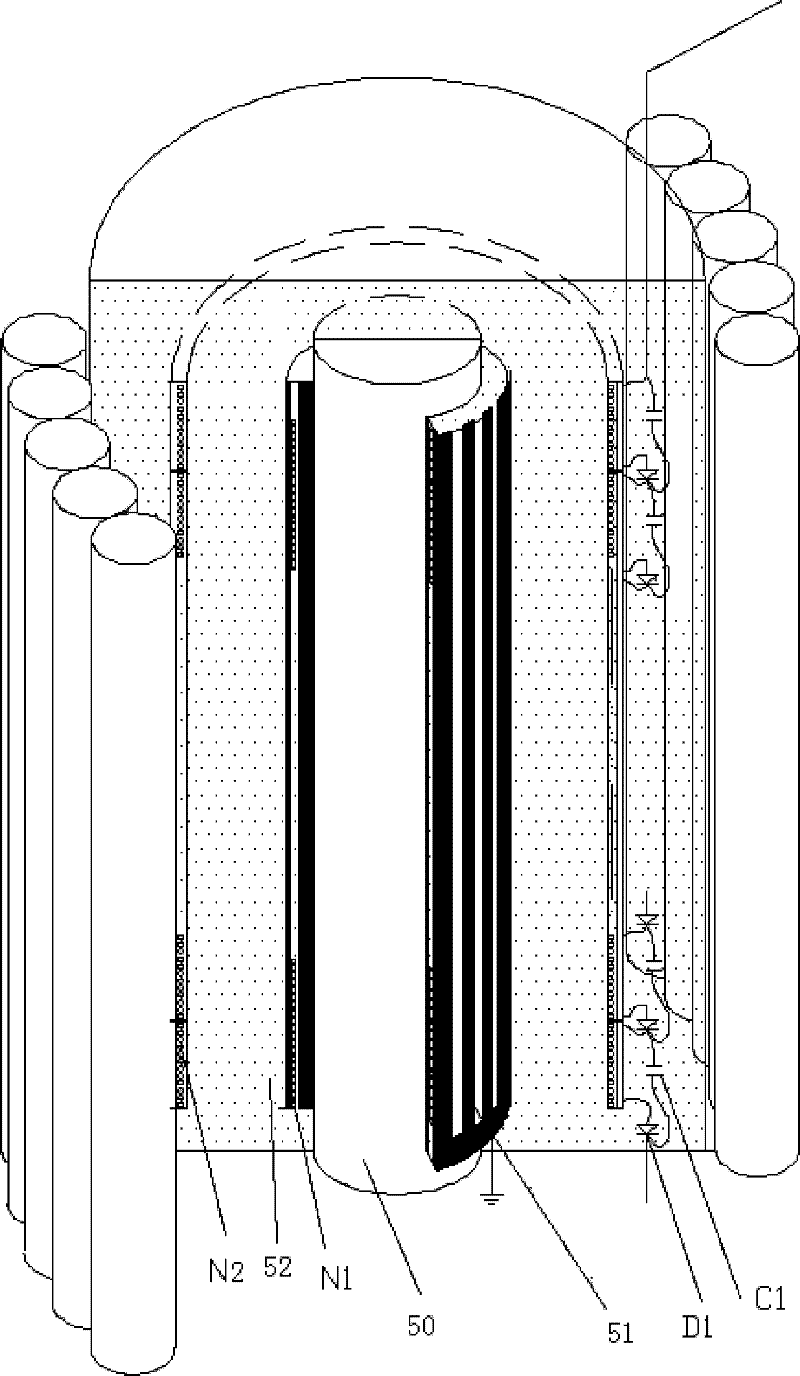

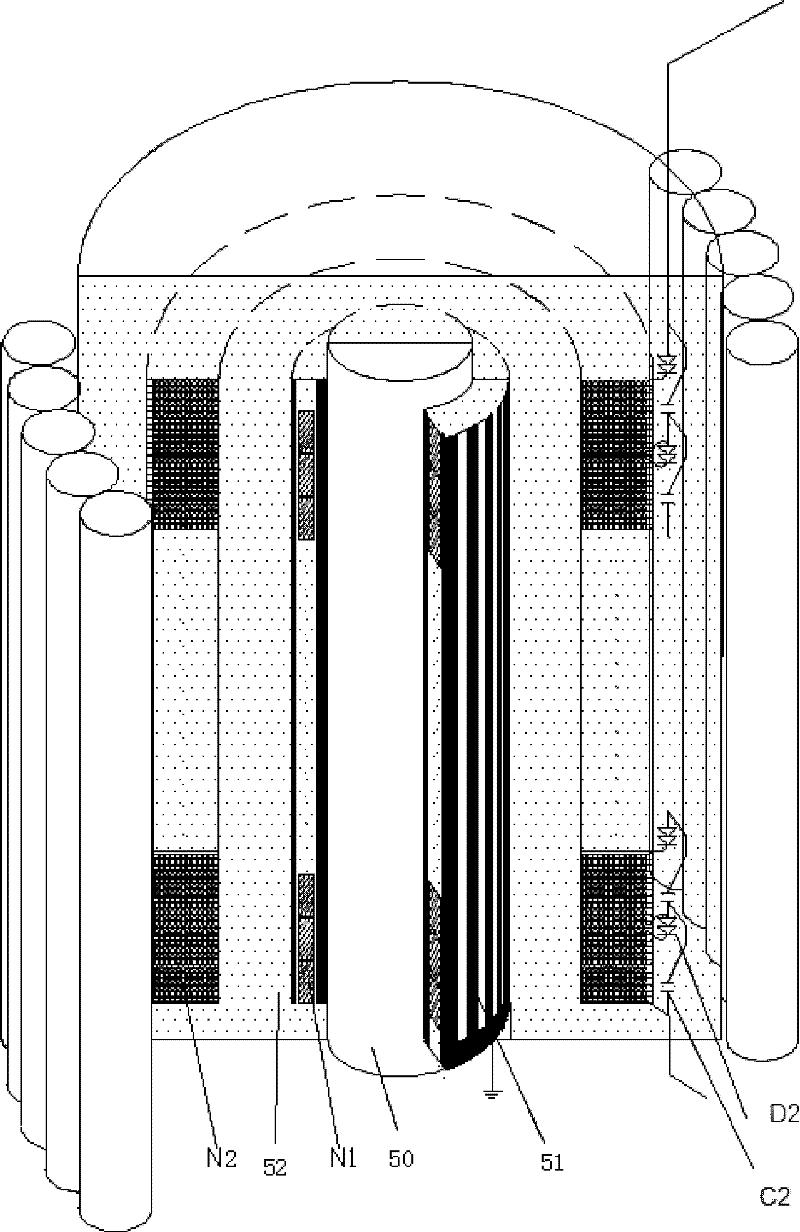

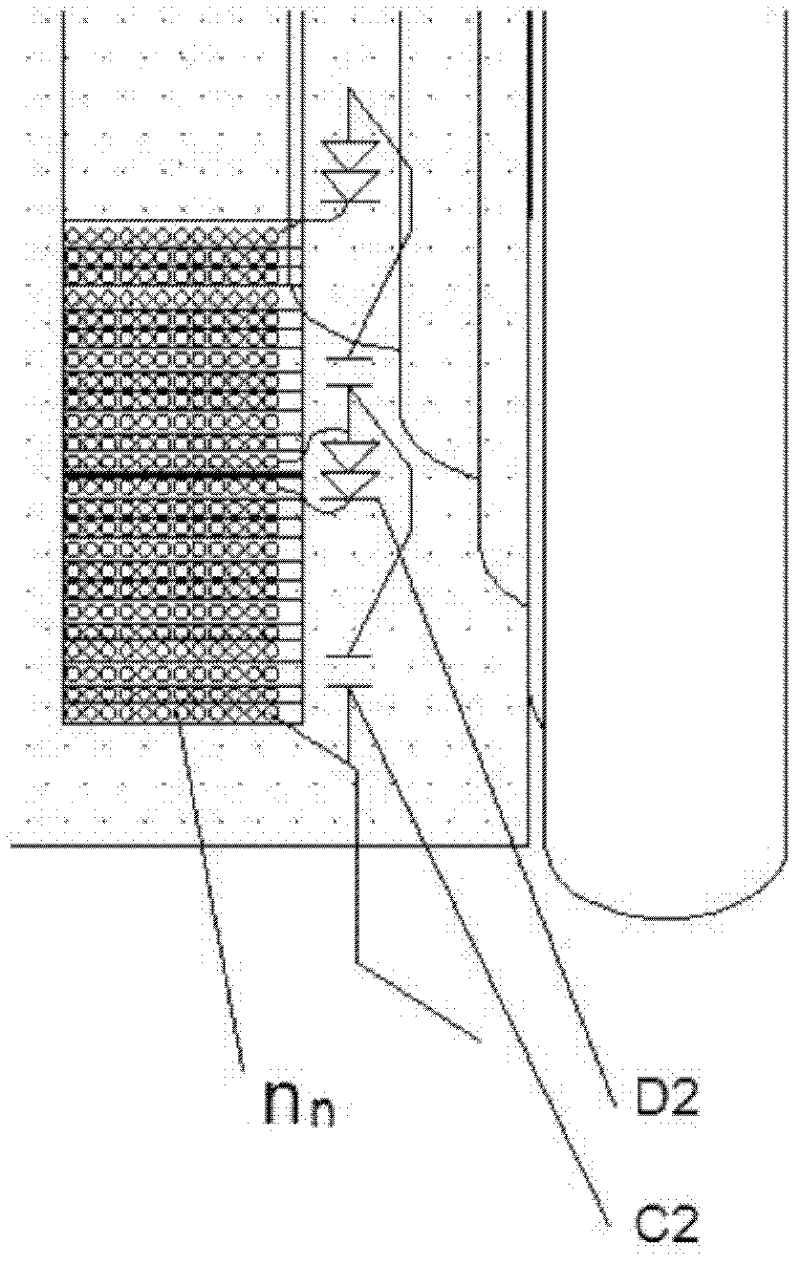

[0018] The high-frequency and high-voltage X-ray flaw detector provided by the patent application of the present invention includes an X-ray tube 21, a filament power supply part A2 and a high-voltage transformer part. The high-voltage transformation part is composed of a high-frequency high-voltage transformer B and a high-frequency driving circuit of the high-frequency high-voltage transformer B. The inner and outer jackets of the insulating shielding layer 52 are placed on the magnetic core 50. The primary winding N1 and the secondary winding N2 are arranged at the same end on the magnetic core 50. Although the number of turns of the primary winding N1 is small, it should be connected with the secondary winding N2. Occupying the same or as close as possible length on the magnetic core, both ends of the primary winding N1 are connected to the driving output of the high frequency driving circuit. The secondary winding N2 is a number of winding segments n arranged sequentially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com