Method for increasing useful component content of plant body in hydroponic culture

A hydroponics and production method technology, applied in botany equipment and methods, horticultural methods, cultivation, etc., can solve the problems of additional energy cost, cost increase, optimal light adjustment, maintenance and management, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

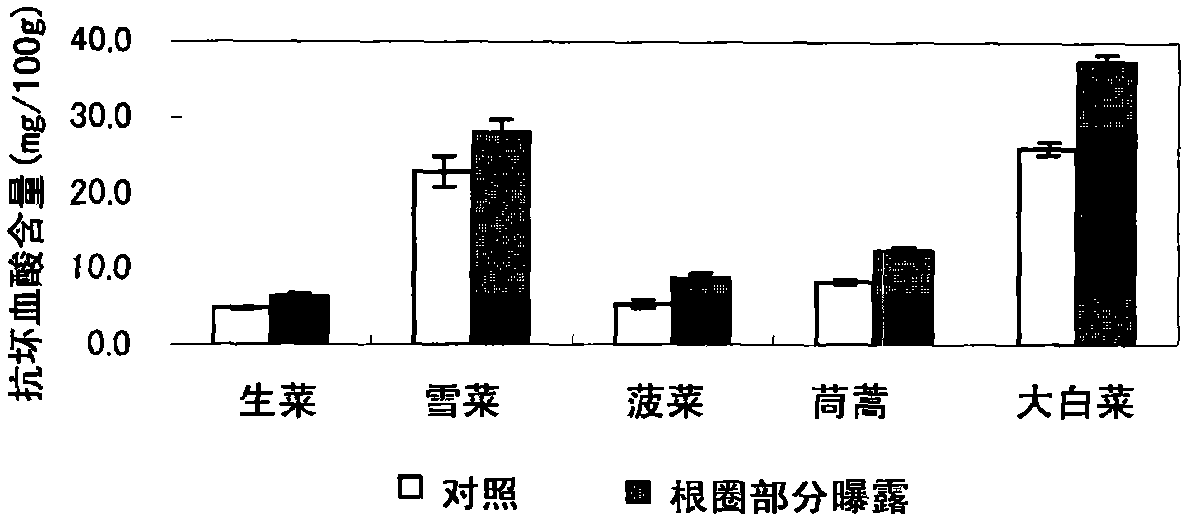

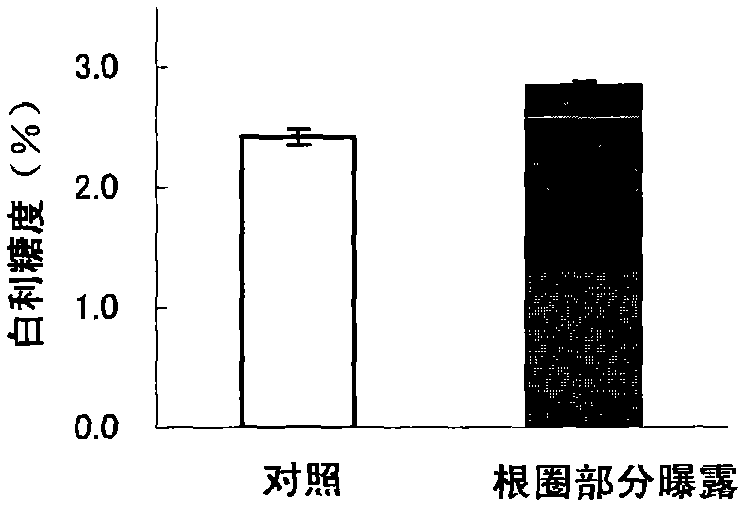

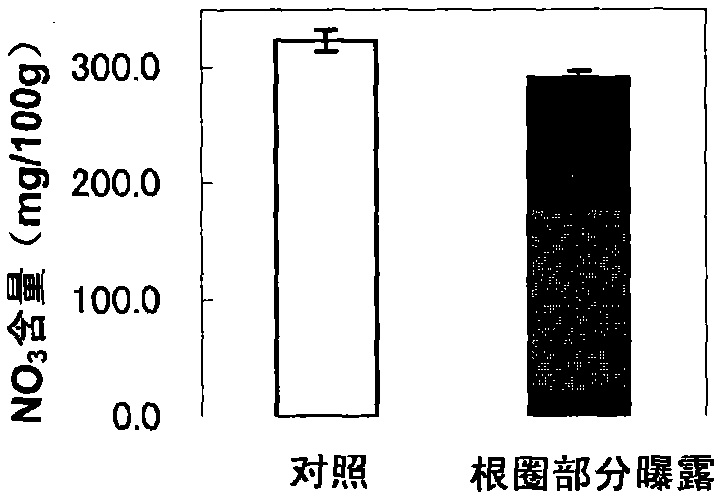

[0031] [Example 1] Root ring exposure experiment in hydroponic culture of lettuce, pickled cabbage, spinach, Abutilon and Chinese cabbage

[0032] Carry out the hydroponic culture of lettuce, pickled cabbage, spinach, Artemisia spp. and Chinese cabbage. The cultivation conditions were a cycle of 14 hours in the light period and 10 hours in the dark period under a white fluorescent lamp, and an aqueous solution of fertilizer (Otsuka Residential Fertilizer Co., Ltd. (Otsuka Hesse fertilizer) SA formula) was used for the culture solution. The composition of the culture solution is shown in Table 1 below.

[0033] Table 1

[0034]

[0035] The seeds of the above plants were sown on urethane medium, and watered under the conditions of irradiation intensity 5000-5500 Lux, room temperature 18-20°C, culture solution concentration EC (conductivity) = 1.0mS / cm6 After 5 days of growth per day, the plants are fixed on the cultivation plate with the roots completely immersed in the culture solu...

Embodiment 2

[0048] [Example 2] Research on the relationship between the exposure length and the content of useful components in the exposure treatment of the root ring

[0049] In the exposure treatment of the root ring part, 10 groups with a gap of 0.5, 1, 2, 4, 5, 10, 15, 20, 25 or 30 cm between the cultivation plate and the liquid surface of the culture solution were set, so as not to be exposed to air The root length (exposure length) of the lettuce was cultivated and harvested in the same manner as in Example 1 except for these lengths. In addition, the group with an average root length of 30.9 cm and an exposure length of 30 cm at the beginning of the root ring part exposure treatment was in a state where only the root tip was immersed in the culture solution. For the harvested lettuce, the ascorbic acid content was measured in the same way as in Example 1.

[0050] The results are shown in Figure 4 . As shown in the figure, no change in ascorbic acid content relative to the control g...

Embodiment 3

[0051] [Example 3] Research on the relationship between the number of days of treatment and the content of useful components in the exposure treatment of the root ring

[0052] In order to study the relationship between the number of days of exposure treatment of the root zone and the content of useful components, lettuce seedlings were grown in the same way as in Example 1 above, and then 4cm was used as the exposure length, at 0, 3, 7, 9, 12 Or expose part of the root ring within 14 days, harvest the plant body, and determine the ascorbic acid content.

[0053] The results are shown in Figure 5 . In the rhizosphere exposure group, ascorbic acid increased to 111% in the rhizosphere exposure treatment for 3 days compared to the control group, and further increased by the 7th day treatment. However, after that, the rate of increase relative to the control group decreased. The result of the 12-day treatment was the same as that of the 3-day treatment, and the result of the 14-day t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com