Advanced wastewater hardness removal method

A waste water, high hardness technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc., can solve the problems of poor water quality, increased treatment costs, scaling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

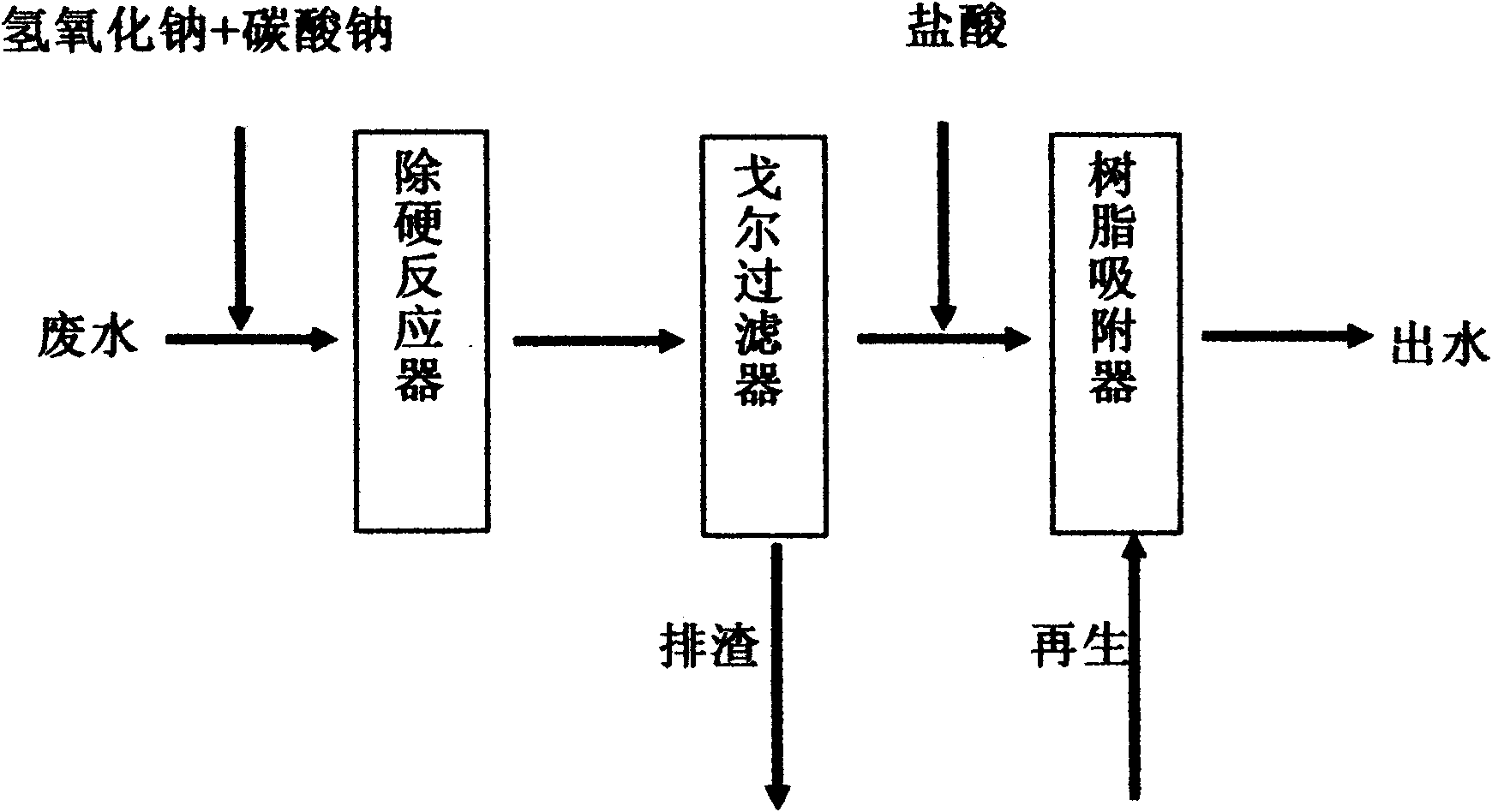

Method used

Image

Examples

Embodiment 1

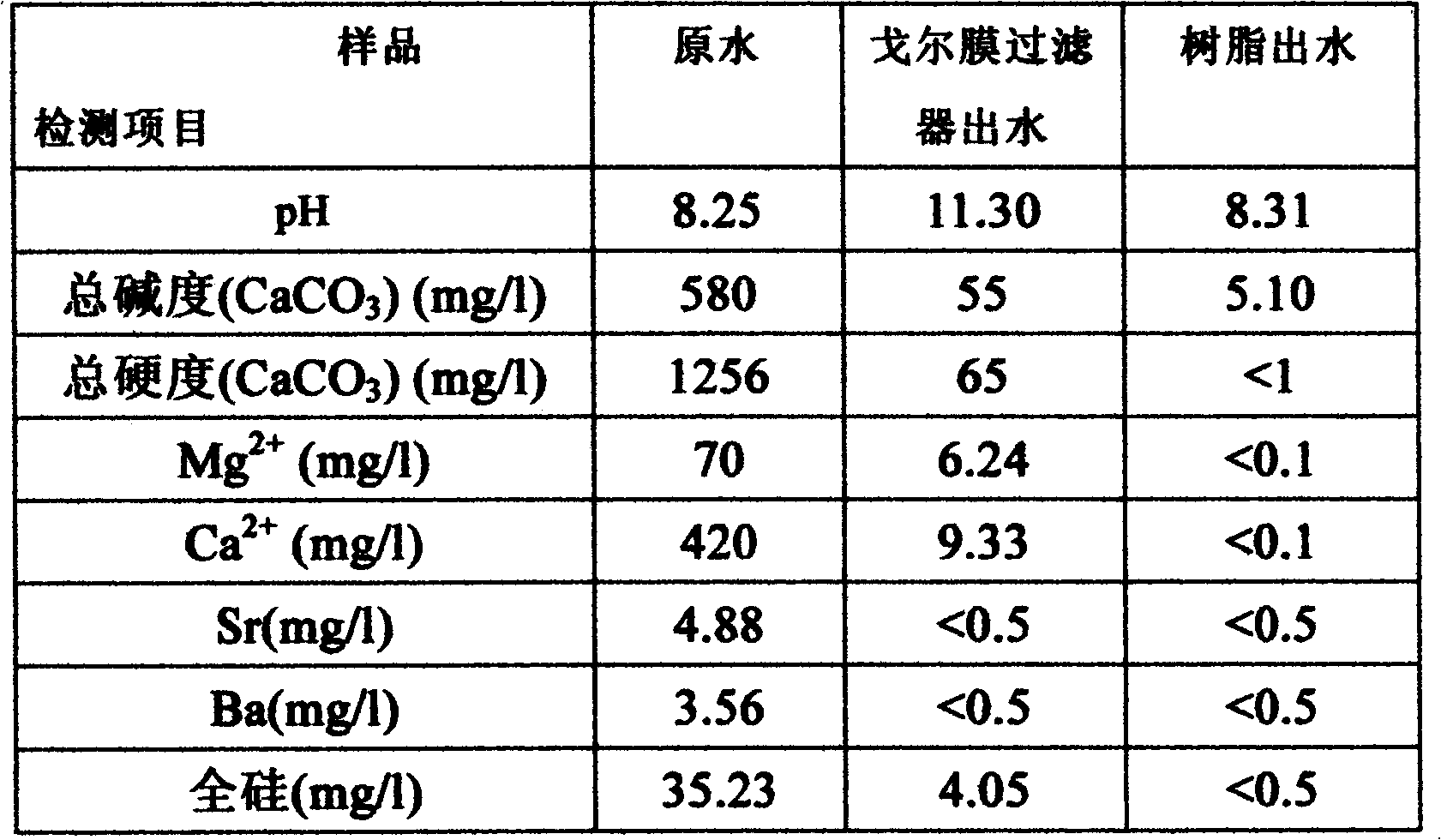

[0016] Reverse osmosis concentrated water in a petrochemical plant up to the standard sewage reuse device, with a treatment capacity of 5m 3 / h, the indicators and treatment results of each pollutant in the wastewater are shown in Table 1.

[0017] The waste water is treated as follows:

[0018] 1) First, add sodium hydroxide (concentration 25%) and sodium carbonate (concentration 10%) to the wastewater at the same time. 30 minutes;

[0019] 2) After the waste water has undergone the dosing reaction, carry out the Gore membrane filter filtration unit to remove a large amount of suspended particles (mainly calcium carbonate and magnesium carbonate) produced in the reaction process, and the residue in the backwash process with a solid content of 3% The concentration solution is discharged from the device, and the filtered water enters the next unit for treatment;

[0020] 3) The wastewater after the Gore membrane filter is adjusted to pH 6.8 with hydrochloric acid (27%), and ...

Embodiment 2

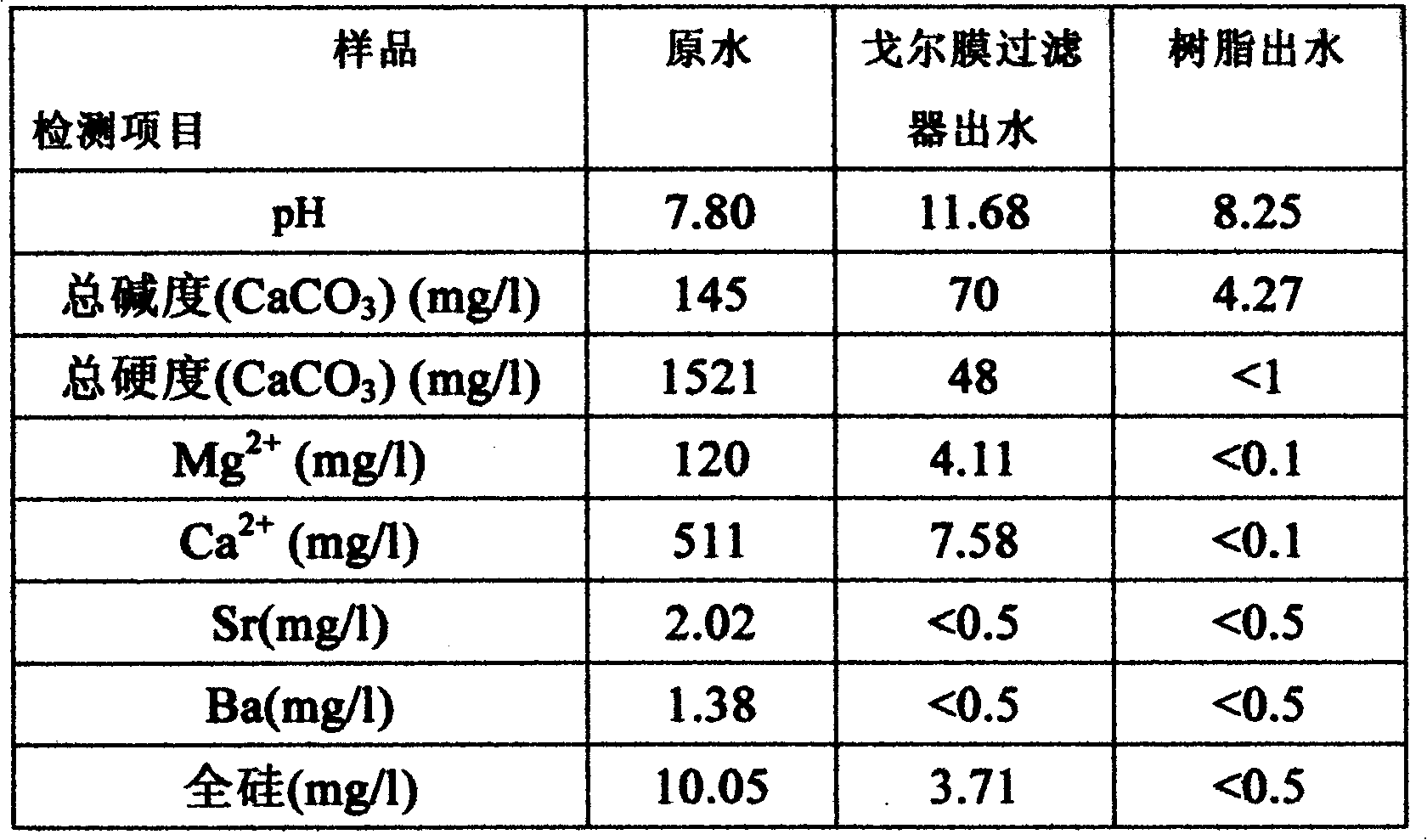

[0024] Underground slightly polluted water in an oil refinery, with a treatment capacity of 100m 3 / h, the indicators of various pollutants in the water body are shown in Table 2:

[0025] The waste water is treated as follows:

[0026] 1) First, add sodium hydroxide (concentration 30%) and sodium carbonate (concentration 20%) to the wastewater at the same time. 90 minutes;

[0027] 2) After the wastewater has undergone the dosing reaction, carry out the Gore membrane filter filtration unit to remove a large amount of suspended particles (mainly calcium carbonate and magnesium carbonate) produced in the reaction process, and the residue in the backwash process with a solid content of 3.5% The concentration is discharged from the device, and the effluent enters the next unit for treatment;

[0028] 3) The wastewater after the Gore membrane filter is adjusted to pH 7.5 with hydrochloric acid (27%), and then enters the resin adsorption unit for deep hard removal treatment to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com