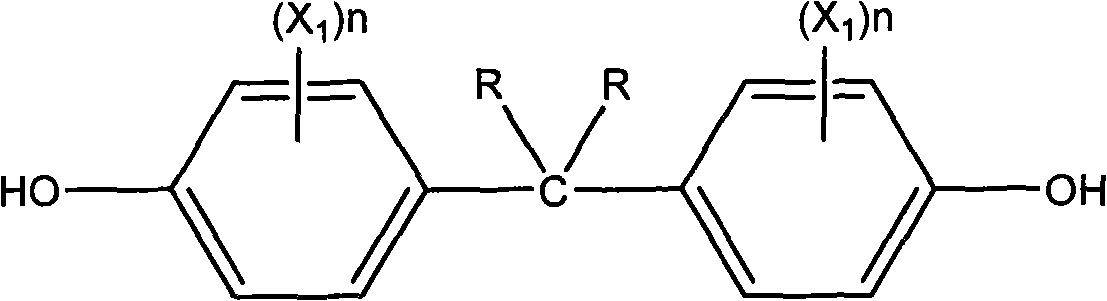

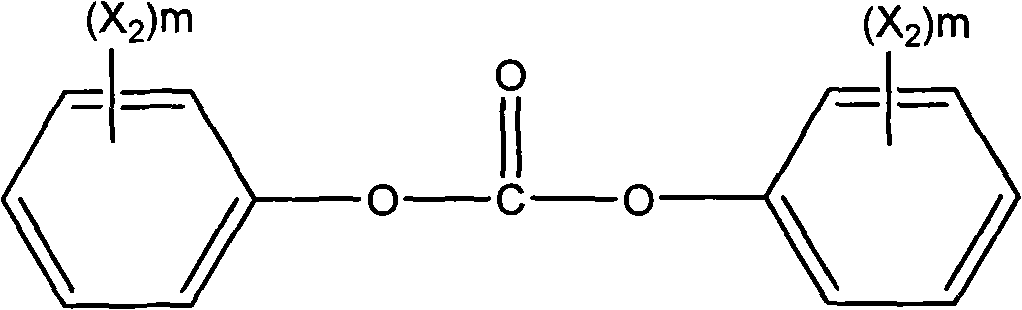

Method for preparing polycarbonate through melt transesterification technology

A polycarbonate and polycondensation technology, applied in the field of transparent polycarbonate, can solve the problems of wide molecular weight distribution of polymers, difficult mass transfer, heat transfer, uneven catalyst distribution, etc., to achieve uniform molecular weight distribution, low reaction temperature, alkali Sexually Moderate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The reaction system consists of heating system, stirring system, condensation system and vacuum system. Carry out transesterification polycondensation reaction in 50ml three-neck bottle.

[0032] Weigh 43.2mmolBPA and 1.08 times DPC, add 2.5×10 -4 LiACAC of mol / molBPA (ACAC is acetylacetone C 5 h 8 o 2 Monovalent anion) aqueous solution (concentration is 4.323×10 -3 mole ml -1 ) as a catalyst, evacuate to a pressure of 4000Pa, and heat to 130°C within 5.0min. After the reactants are melted, start to stir. After 30 minutes of reaction, start to raise the temperature, rise to 160°C for 5 minutes, react for 20 minutes, then rise to 180°C for 5 minutes, react for 10 minutes, then reduce the pressure to 100Pa, rise to 220°C for 5 minutes, react for 5 minutes, and then The temperature was raised to 250°C in 5 minutes, reacted for 5 minutes, and then stopped the reaction.

[0033] The obtained products were subjected to the following determinations:

[0034] Viscosity ...

Embodiment 2-4

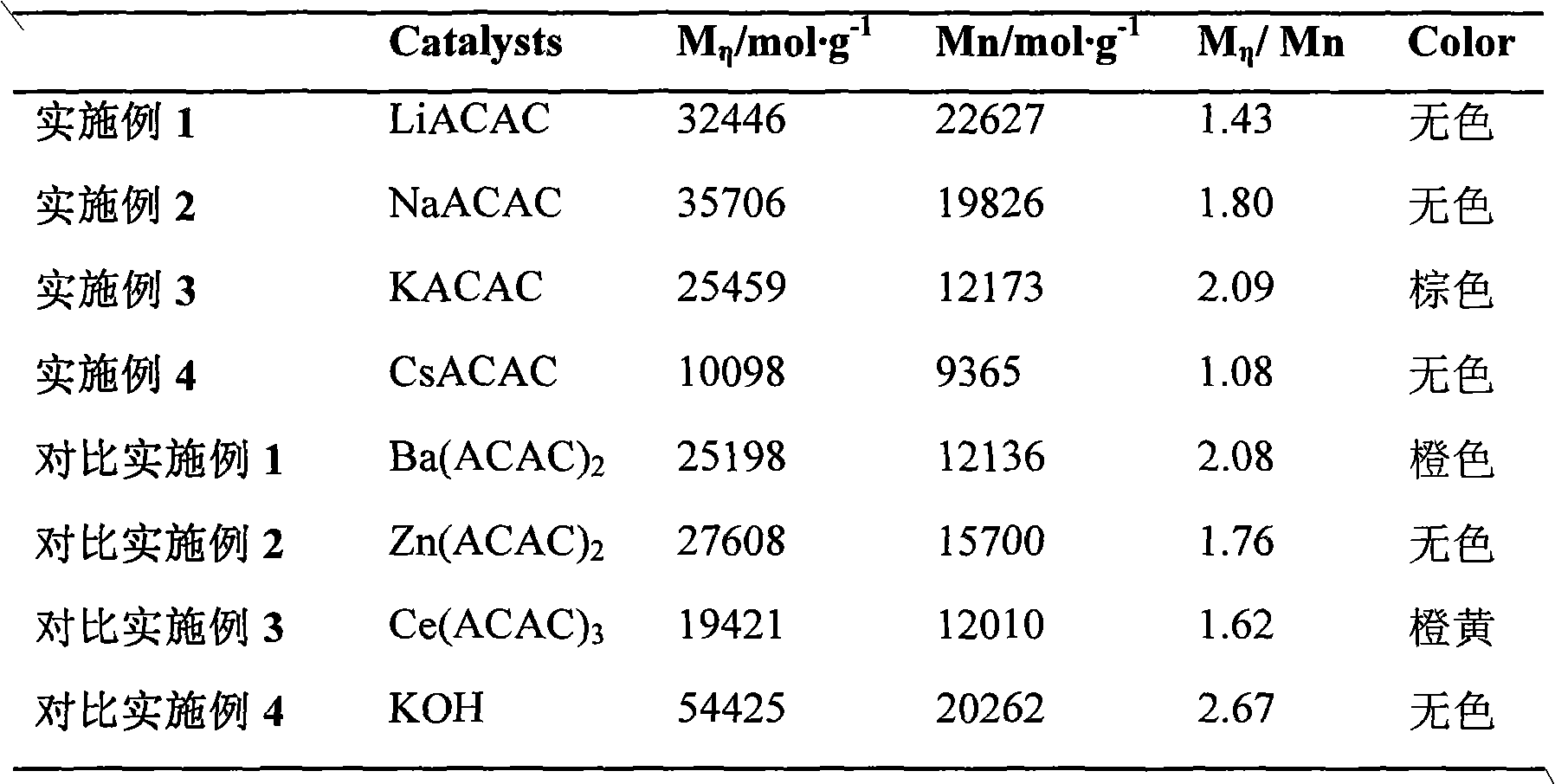

[0040] Under the same conditions, the experimental results of the alkali metal acetylacetone catalyst are listed in Table 1:

Embodiment 5-8

[0046] Under the same conditions, the experimental results of the lithium acetylacetonate catalyst of different consumptions are listed in Table 2:

[0047] The experimental result of table 2 different dosage lithium acetylacetonate catalyst

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com