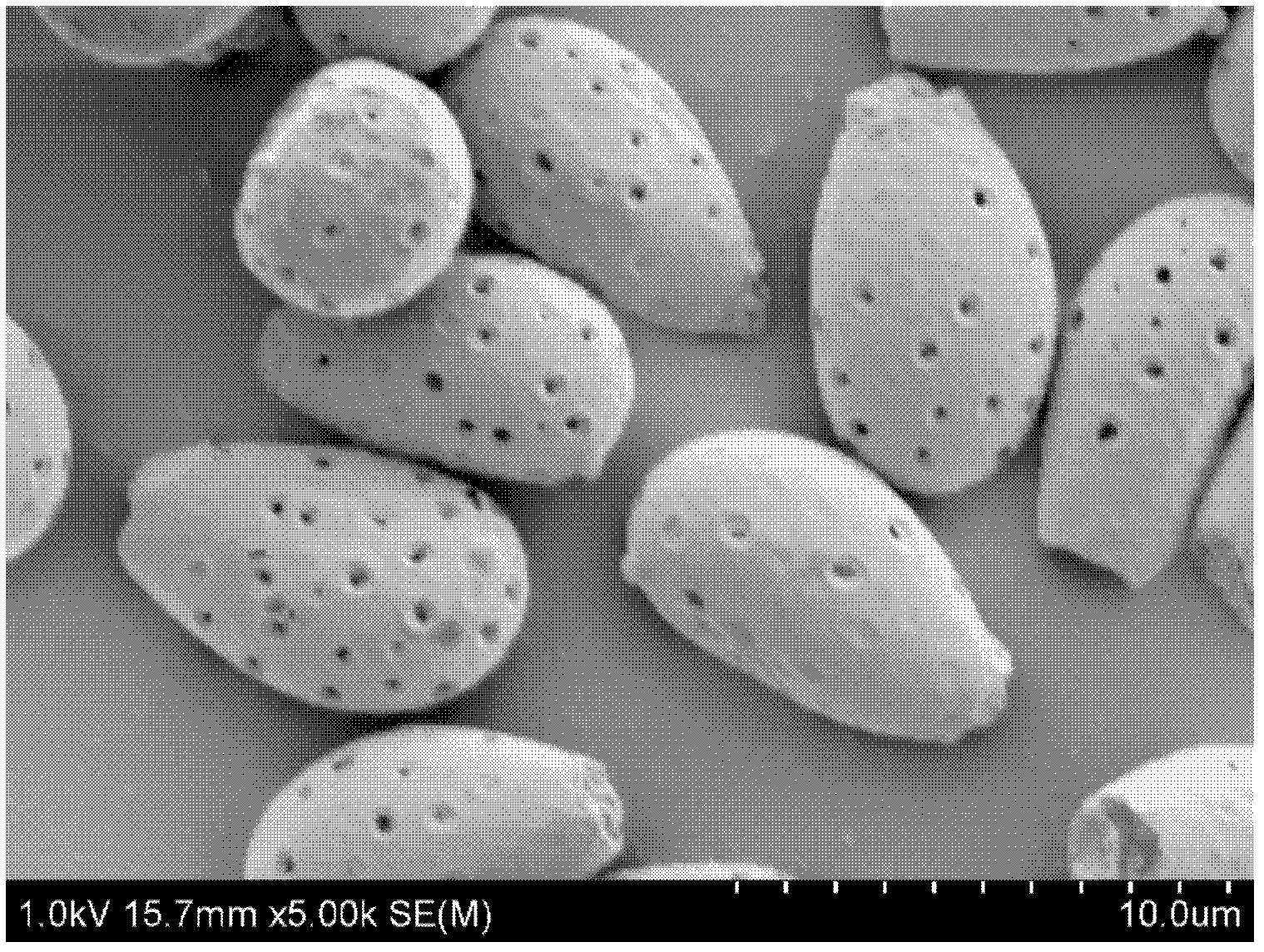

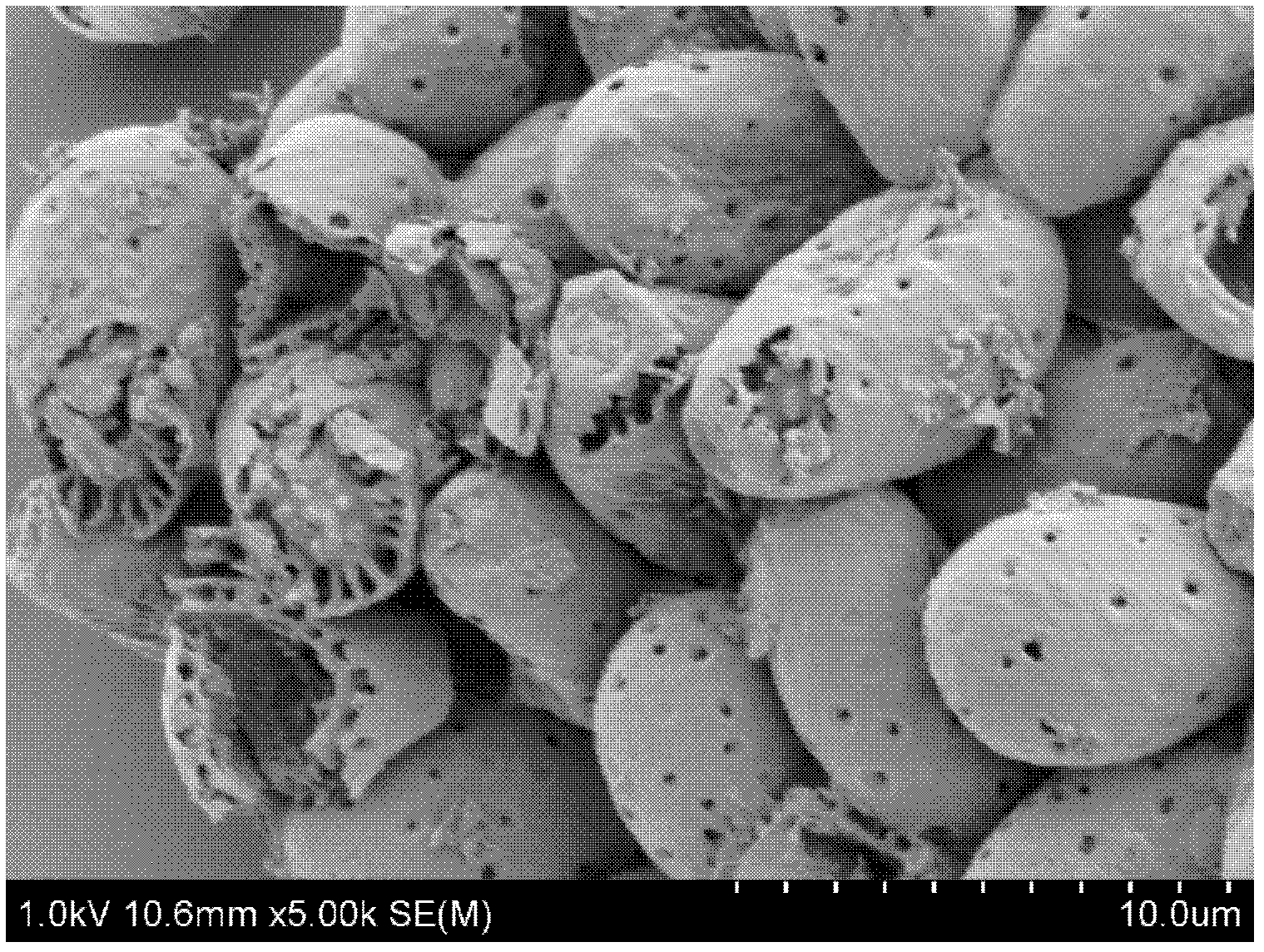

Wall breaking method for fresh and live ganoderma lucidum spores

A fresh technology of Ganoderma lucidum spores, which is applied in the direction of medical formulas, medical preparations containing active ingredients, anti-toxins, etc., can solve the problems of changing natural ingredients, dampness of Ganoderma lucidum spore powder, cumbersome steps, etc., to achieve increased antioxidant activity, Ease of large-scale production and long storage period at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for breaking the wall of fresh ganoderma lucidum spores, the method steps are as follows:

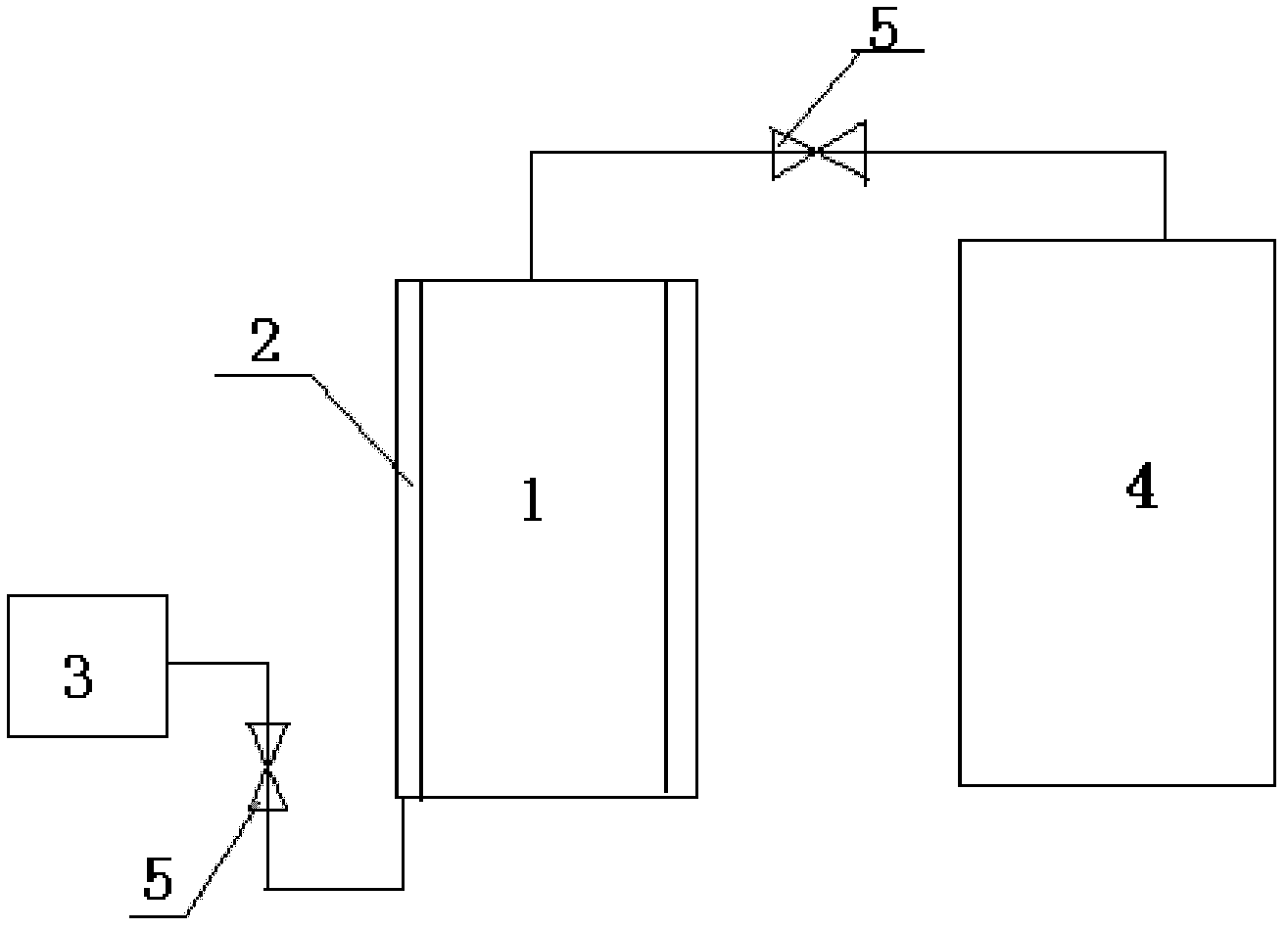

[0047] 1) Put fresh Taishan red ganoderma spores into the pressure tank in the puffing equipment, the amount of ganoderma spores is 10% of the volume of the pressure tank by volume ratio, and seal the pressure tank;

[0048] 2) Turn on the steam generator in the puffing equipment to generate steam; when the pressure in the steam generator reaches 0.35MPa, open the valve between the steam generator and the pressure tank, and pass steam into the interlayer of the pressure tank to the pressure tank Heating the Ganoderma lucidum spores: the temperature of the Ganoderma lucidum spores is 80°C and the pressure in the pressure tank is 0.02MPa, and kept for 20min;

[0049] 3) Vacuum the vacuum tank of the puffing equipment, the pressure is ≤0.1MPa, open the valve between the vacuum tank and the pressure tank in the puffing equipment for instant pressure relief, and use the insta...

Embodiment 2

[0054] 1) Put fresh Korean red ganoderma spores into the pressure tank in the puffing equipment, the amount of ganoderma spores is 15% of the volume of the pressure tank by volume ratio, and seal the pressure tank;

[0055] 2) Turn on the steam generator in the puffing equipment to generate steam; when the pressure in the steam generator reaches 0.4MPa, open the valve between the steam generator and the pressure tank, and pass steam into the interlayer of the pressure tank. Heating the Ganoderma lucidum spores: the temperature of the Ganoderma lucidum spores is 90°C and the pressure in the pressure tank is 0.02MPa, and kept for 15min;

[0056] 3) Vacuum the vacuum tank of the puffing equipment, the pressure is ≤0.1MPa, open the valve between the vacuum tank and the pressure tank in the puffing equipment for instant pressure relief, and use the instantaneous temperature change and pressure difference to puff and dry the ganoderma spores; The time to open the valve between the p...

Embodiment 3

[0061] 1) Put fresh Japanese red ganoderma spores into the pressure tank in the puffing equipment, the amount of ganoderma spores is 12% of the volume of the pressure tank in terms of volume ratio, and seal the pressure tank;

[0062] 2) Turn on the steam generator in the puffing equipment to generate steam; when the pressure in the steam generator reaches 0.36MPa, open the valve between the steam generator and the pressure tank, and pass steam into the interlayer of the pressure tank to the pressure tank Heating the Ganoderma lucidum spores: Make the temperature of the Ganoderma lucidum spores to be 90°C and the pressure in the pressure tank to be 0.02MPa for 20min;

[0063] 3) Vacuumize the vacuum tank of the puffing equipment, the pressure is ≤0.1MPa, open the valve between the vacuum tank and the pressure tank in the puffing equipment for instant pressure relief, and use the instantaneous temperature change and pressure difference to puff and dry the ganoderma spores; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com