Catalyst for producing synthesis gas by reforming natural gas and carbon dioxide and preparation method thereof

A carbon dioxide and natural gas technology, applied in petrochemical, natural gas chemical, and catalyst fields, can solve the problems of catalyst bed blockage, high price, decreased activity, etc., and achieve good activity and stability, low cost, and reduced carbon generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

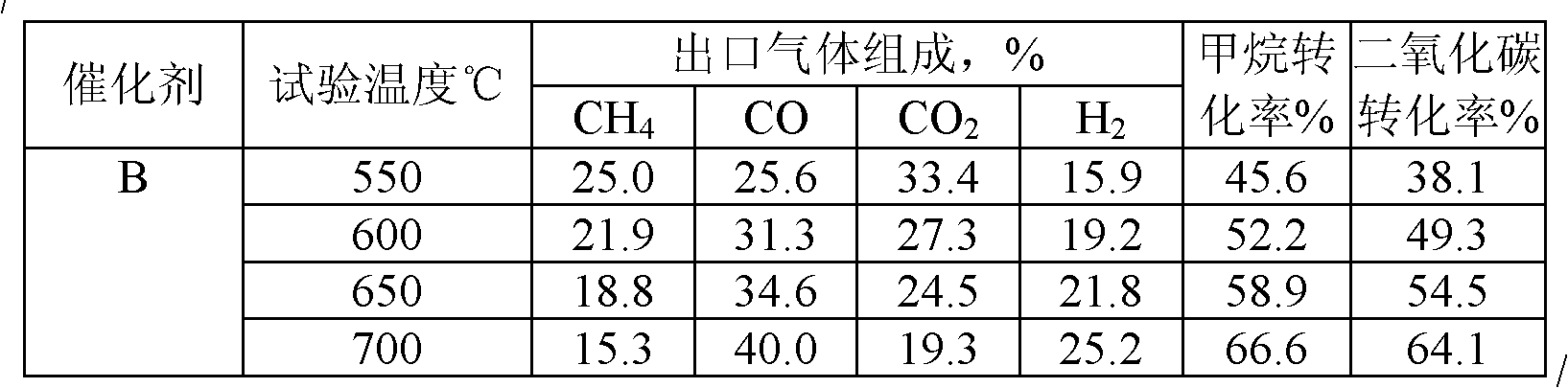

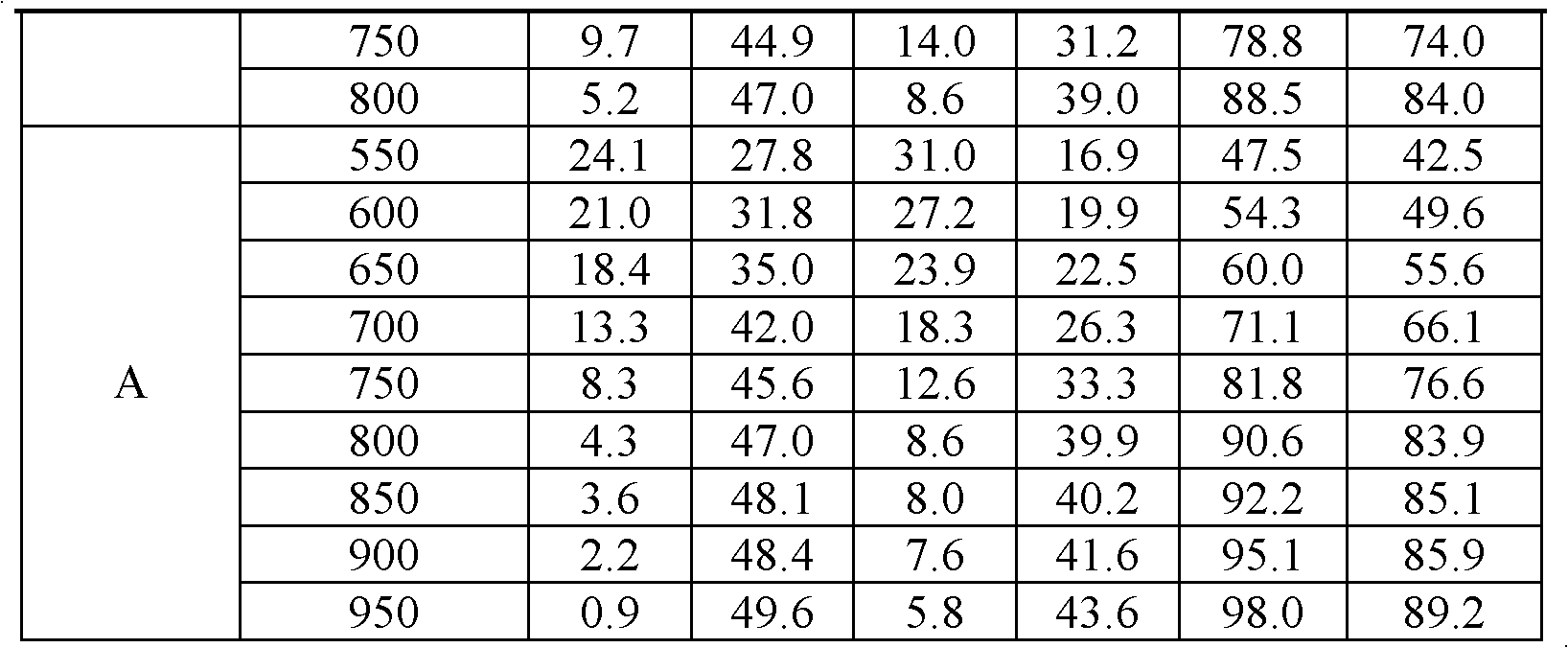

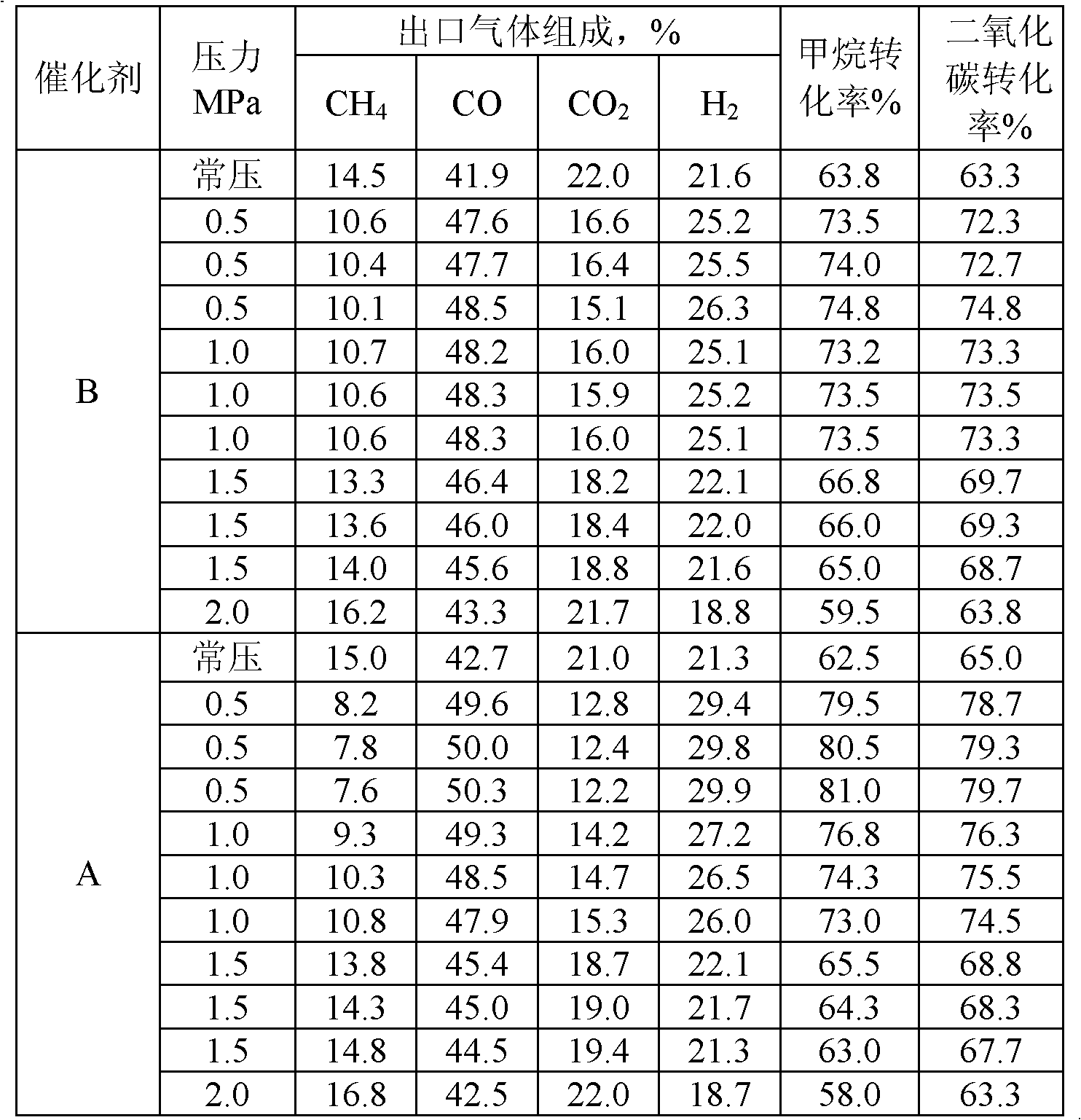

Examples

Embodiment 1

[0021] Preparation of Catalyst A

[0022] 20g of citric acid is prepared into 450ml of aqueous solution, 980g of pseudo-boehmite and 20g of fennel powder are dry-mixed evenly, the solution is added to it, kneaded and extruded, dried at 100-110°C for 6 hours, and then calcined at 950°C After 4 hours, a bar-shaped or Raschig ring carrier was prepared. Carrier specific surface 130m 2 / g, the specific pore volume is 0.43ml / g, and the phases are α, δ, θ-Al 2 o 3 Miscible. Weigh 953g of nickel nitrate and 259g of lanthanum nitrate, dissolve them in water, and prepare 1L of nickel-lanthanum mixed solution.

[0023] Take the above-mentioned carrier and immerse it in the solution, take it out after 120 minutes, drain it, dry it, and roast it to prepare Catalyst A. Analyze its composition as:

[0024] components

Embodiment 2

[0026] Preparation of Catalyst B

[0027] 40g of citric acid is prepared into 200ml of aqueous solution, 960g of pseudoboehmite and 40g of turnip powder are dry-mixed evenly, the solution is added to it, kneaded, dried, pressed into sheet shape, Raschig ring, spherical shape, and dried at 100-110°C 6 hours, and then calcined at 1020°C for 3 hours to obtain a strip-shaped or Raschig ring carrier. Carrier specific surface 112m 2 / g, the specific pore volume is 0.35ml / g, and the phases are α, δ, θ-Al 2 o 3 Miscible.

[0028] Weigh 190g of lanthanum nitrate, dissolve it in water, and prepare 1L of lanthanum solution.

[0029] Weigh 905g nickel nitrate, dissolve it in water, and prepare 1L nickel solution.

[0030] The above-mentioned carrier is immersed in the lanthanum solution, taken out after 60 minutes, drained, dried and roasted; then immersed in the nickel solution, taken out after 120 minutes, drained, dried and roasted to obtain catalyst B.

[0031] Analyze its compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com