Preparation method of high-purity mixed sodium deoxyribonucleotide

A high-purity sodium deoxynucleotide technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems that deoxynucleosides cannot be effectively removed, and the content of finished products can only reach 75%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

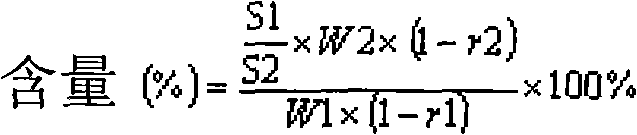

Image

Examples

Embodiment 1

[0036] Dissolve 500g of DNA in 50L of distilled water, adjust the pH to about 5.4 with hydrochloric acid, heat up to 90°C for 10 minutes, cool to 71°C, add 10g of 5'-phosphodiesterase (8000 units / g enzyme activity, first use distilled water Make into a paste and keep warm at 72°C for 8 minutes. React for 3 hours, then heat up to 90°C and keep warm for 10 minutes (to inactivate 5'-phosphodiesterase) to stop the reaction. Cool the solution to below 40°C and adjust the pH to 10, filter Impurities such as protein are removed to obtain an enzymolysis solution for subsequent use. Wherein: the weight content of mixed deoxynucleotide sodium is 50% to 60%;

[0037] Prepare 3 chromatographic columns, No. 1 is equipped with 4L HZ-201 anion resin, No. 2 is equipped with 4LHZ-201 anion resin, and No. 3 is equipped with 5L769 activated carbon. The method reported by "Animal Biochemical Pharmacy" People's Health Publishing House in February, 1981 carried out regeneration treatment to No. 1 a...

Embodiment 2

[0044] The same method as in Example 1 was used to obtain the enzymatic hydrolyzate for subsequent use. Wherein: the weight content of mixed deoxynucleotide sodium is 50-60%;

[0045] Prepare 3 chromatographic columns, No. 1 is equipped with 4L 711 anion resin, No. 2 is equipped with 4L711 anion resin, and No. 3 is equipped with 5L G15 activated carbon; the regeneration treatment is the same as in Example 1.

[0046] Load the reaction filtrate through columns No. 1 and No. 2 in series; after loading the sample, wash the column with 2 times the column volume of distilled water until the pH of the effluent from the outlet of No. Pass the hydrochloric acid solution into No. 1 column to wash the column until the pH of the effluent at the outlet of No. 2 column is 3.0. At this time, various deoxynucleoside impurities on the column can be washed away;

[0047] Then pass into No. 1 column elution with the mixed solution of sodium chloride and acid, and No. 2 column effluent is all p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com