High-performance viscosity-controllable silicon-based heat conducting paste and preparation method thereof

A heat-conducting paste, silicon-based technology, applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems that the viscosity of the heat-conducting silicone grease composition cannot be controlled at will, and the preparation method is complicated, so as to achieve improved stability, easy preparation, The effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

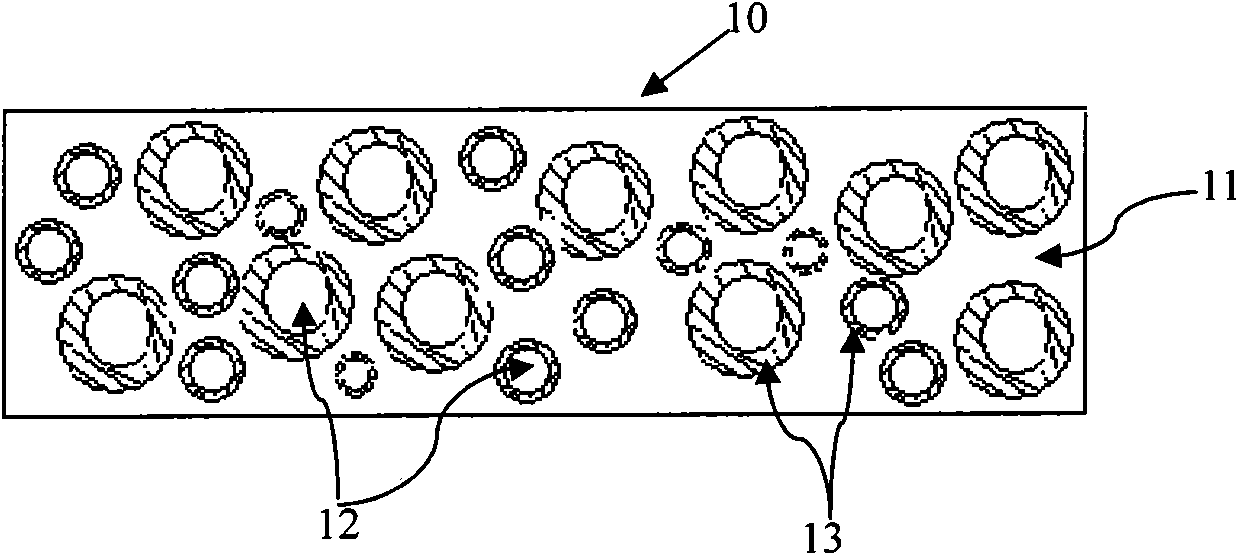

[0022] The preparation method of the silicon-based thermal paste of the present invention is described below.

[0023] As mentioned above, the method for preparing silicon-based thermal paste in the present invention can be divided into: mixing a part by weight of matrix 11 and part by weight of viscosity modifier 13 in a reactor at a temperature of 0°C to 50°C, and mixing them at a lower speed Stir to make the matrix and the viscosity regulator mix evenly; then keep the temperature constant, add c parts by weight of the filled thermal conductive powder 12 to the reactor at one time or divide it into 2 to 5 equal parts or unequal parts, and at the same time Stir in a vacuum state, and adjust the stirring speed from a lower speed to a higher speed during each addition of the heat-conducting powder. After stirring until the mixture is uniform, adjust the stirring speed to a lower speed, and repeat The above operation of adding the filled thermal conductive powder is carried out ...

Embodiment 1~4

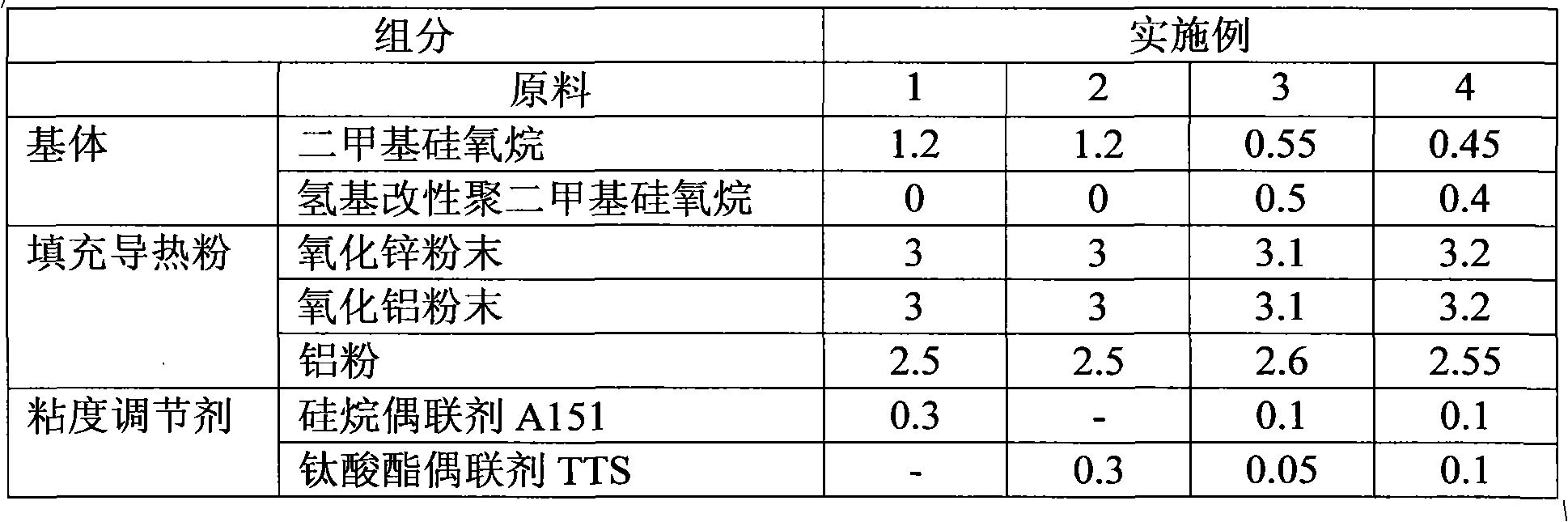

[0032] (1) Raw materials

[0033] Embodiments of the present invention have selected the following materials as raw materials, and weighed according to the weight ratio of raw materials:

[0034] ①Matrix:

[0035] Dimethicone (manufactured by Dow Corning, the brand is XIAMETER's simethicone), the viscosity is 50mm 2 / s and

[0036] Phenyl-modified polydimethylsiloxane (manufactured by Japan Shin-Etsu Corporation), viscosity is 1000mm 2 / s.

[0037] ②Fill with thermal powder:

[0038] Zinc oxide powder with an average particle size of 0.5 μm to 2 μm (activated zinc oxide manufactured by Changzhou Yuanchao Chemical Co., Ltd.),

[0039] Alumina powder, the average particle size is 3 μm~5 μm (manufactured by Aluminum Corporation of China),

[0040] Aluminum powder with an average particle size of 10 μm to 20 μm (manufactured by Henan Donghua Metal Powder Co., Ltd.).

Embodiment 1

[0042] Embodiment 1 has used silane coupling agent A151 (manufactured by U.S. Union Carbide Corporation),

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com