Sintering shaft kiln of phosphate pellets

A technology of pelletizing and shaft kiln, which is applied in the field of shaft kiln for sintering of phosphate rock pellets, which can solve problems such as impacting the environment, secondary pollution, and backlog of funds, and achieve the effects of reducing pollution, saving energy, and reducing the ratio of coke into the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

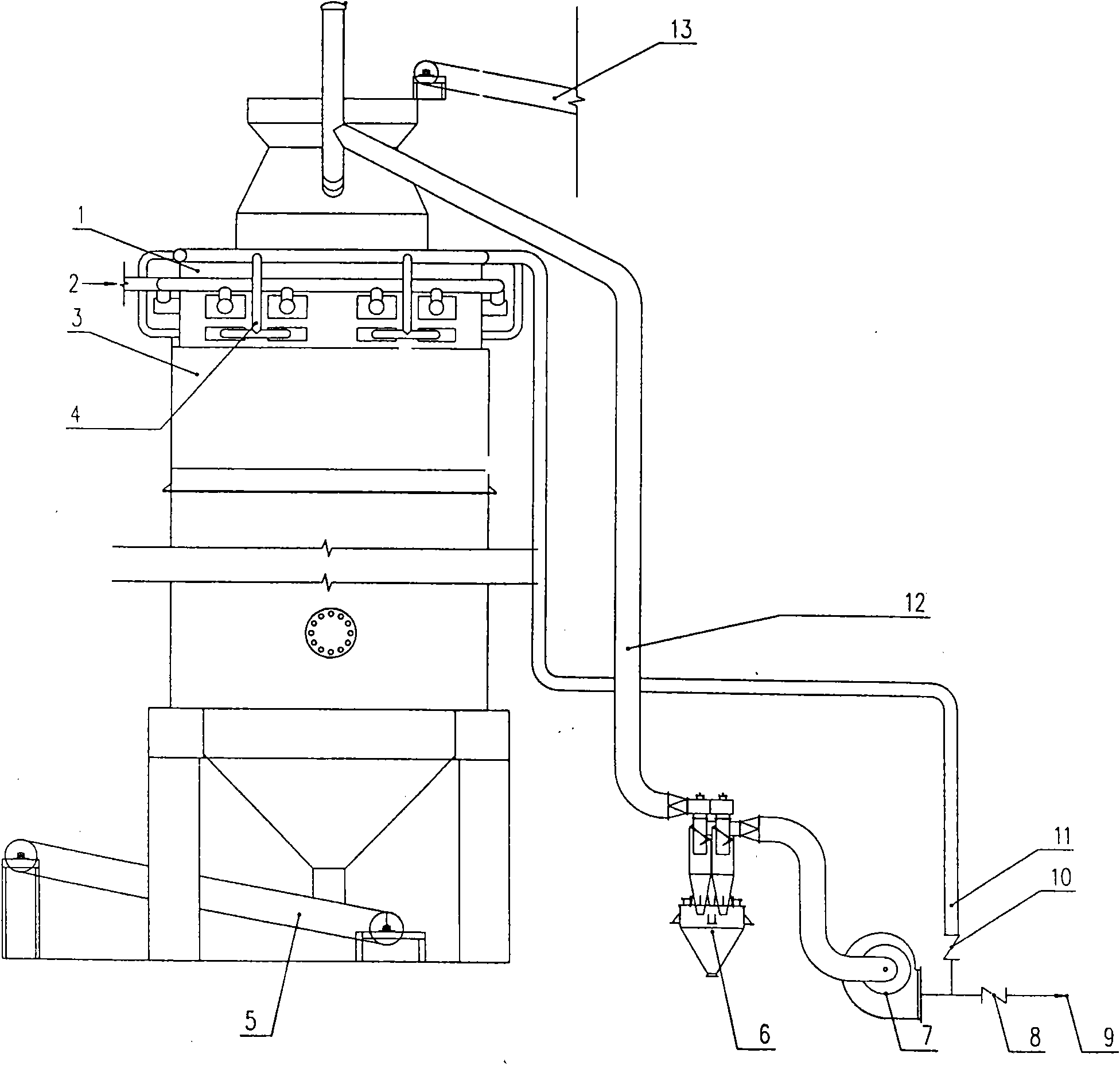

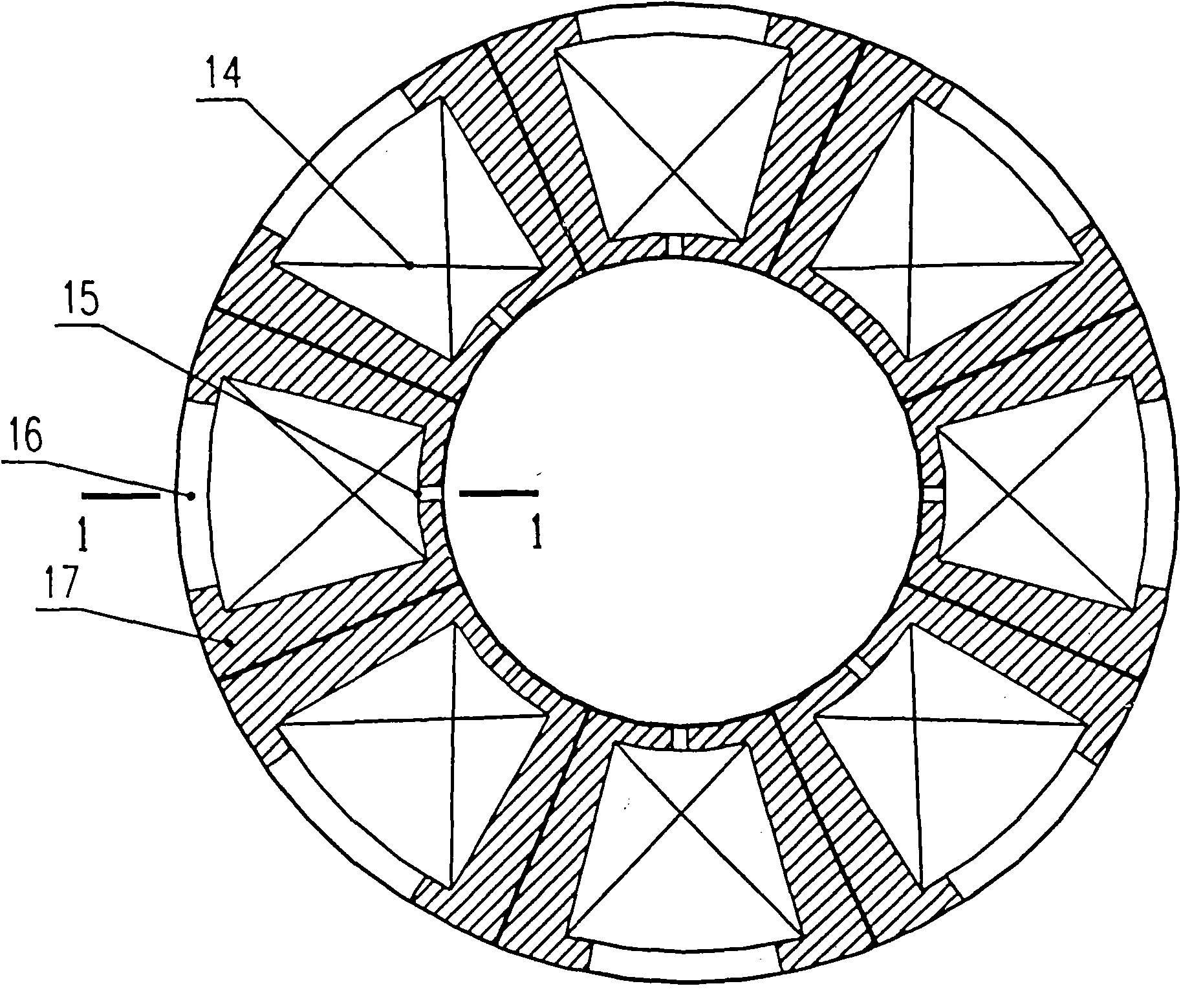

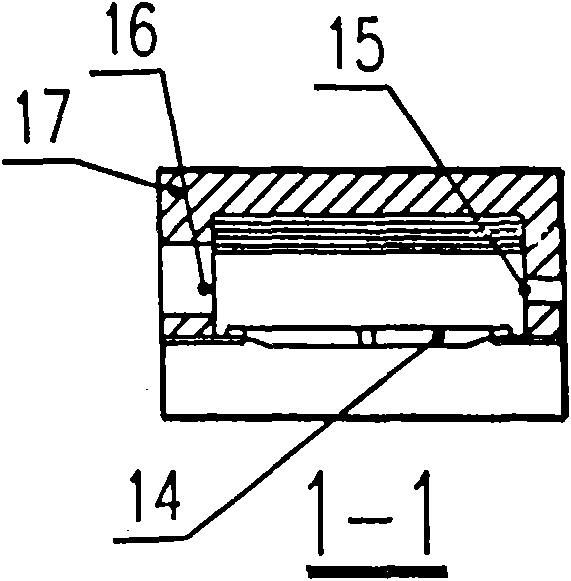

[0012] Below in conjunction with accompanying drawing, as an embodiment, the scheme is described in detail.

[0013] The belt conveyor 13 transports the green pellets to be sintered from the kiln roof to the kiln cavity. The ring-shaped reverberatory furnace body 1 has eight furnace chambers of uniform size and surrounds the upper periphery of the vertical kiln in a ring shape, and heat energy is provided from the middle and upper part of the vertical kiln from the outside to the inside. The central reverberatory furnace flame port 15, the combustion port 16 made in the middle of the reverberatory furnace outer wall, and the furnace body 17 made of refractory bricks; the combustion-supporting air pipe 4, the gas pipe 2 and its burner are installed on its periphery. . The gas pipe 2 is to provide gas source for the combustion of the annular reverberatory furnace, and it is fixed around the outer wall of the reverberatory furnace, so as to transport the gas drawn from the blast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com