Sliding electrical contact material with high rare earth content

A technology with sliding electrical contact and high rare earth content, applied in contacts, circuits, electric switches, etc., can solve problems such as shrinkage cavity, shrinkage porosity, composition segregation, etc., to increase the ability of arc erosion resistance, increase recrystallization temperature, Increased lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

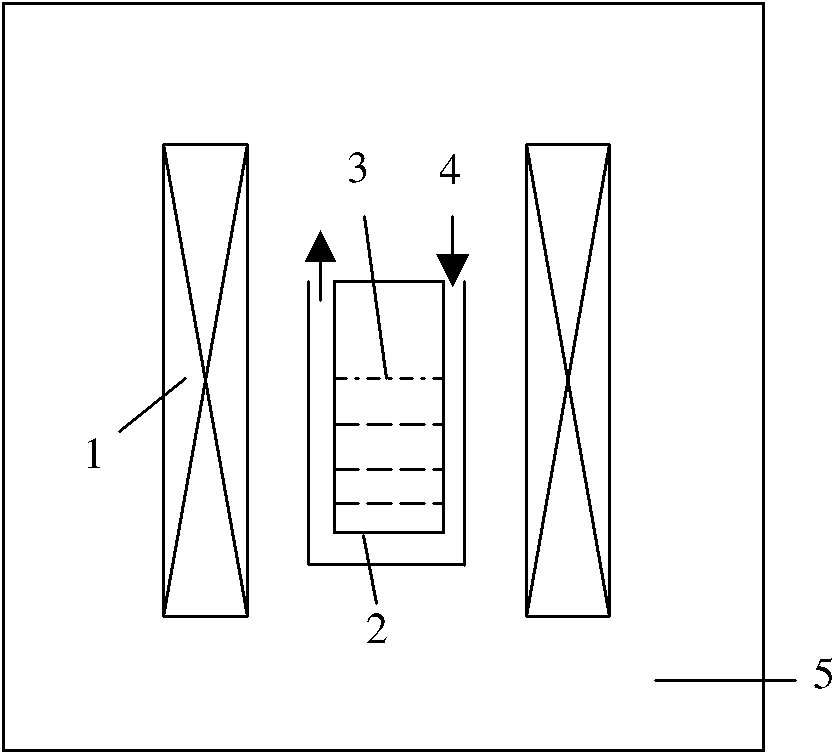

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment describe in detail. The chemical composition of the sliding electrical contact material of the present invention is shown in Table 1. Table 1 lists the chemical composition (Wt.%) of the sliding electrical contact materials of 1# -11# samples, and the 0# sample is a comparative sample without Re (rare earth) elements.

[0020] In the prepared raw materials of each sample, the content of Cu is 4Wt%, the content of Ni is 0.5Wt%, the content of Re element is selected in the range of 0-2.2 Wt%, and the rest is Ag.

[0021] The Re element of 1#-4# sample adopts Y element. 5#-11# sample Re element adopts La element and Y element, among them, the weight ratio of one kind of rare earth element and another kind of rare earth element with the best content is 1:1.25-7. For example, the La content in the 7# sample is 0.2Wt%, the Y content is 1.4Wt%, and the weight ratio of the two before and after is 1:7; and for example, the La content in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com