Oil-emulsion vaccine for poultry and preparation method thereof

An oil emulsion and vaccine technology, applied in the field of vaccines and their preparation, can solve problems such as troublesome adjustment of colloid mill, influence on product quality and titer, system damage, etc., and achieve mass production problems, stability problems, and stable emulsification conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

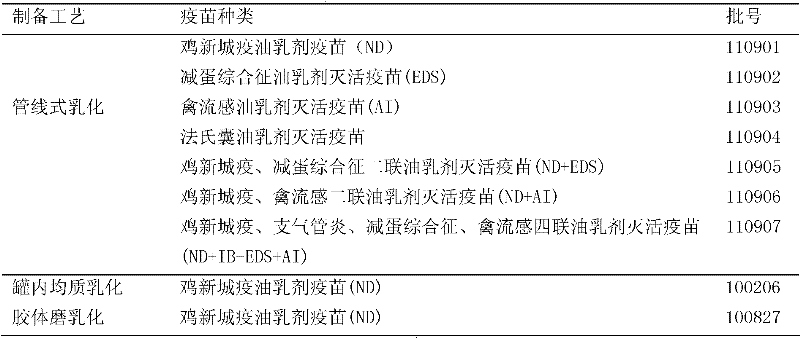

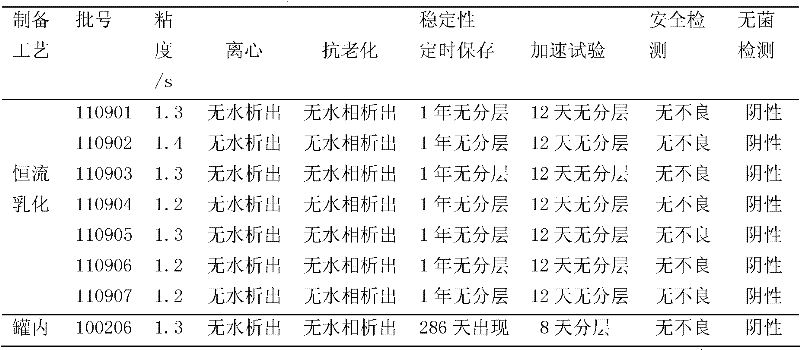

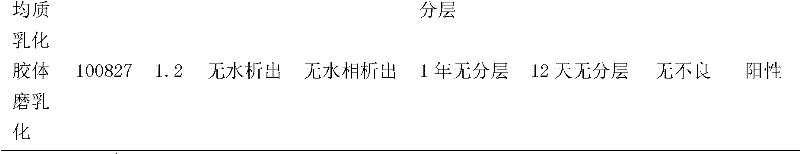

Method used

Image

Examples

Embodiment 1

[0041] Prepare 2 million ml Newcastle disease oil emulsion inactivated vaccine.

[0042] Add 632,700 ml of concentrated Newcastle disease antigen to inactivation and add 33,300 ml of Tween-80 for later use. Take 1.2551 million ml (density 0.818g / ml, 1026.7kg) of white oil, first add 65,920 ml of Span-80 (density 0.994g / ml, 65.5kg), add 21.8kg of aluminum stearate, and heat at 120°C Stir well until the solution is transparent. Add it to the first emulsification reaction kettle, when the temperature drops to 35°C, open the emulsification device, and at the same time turn on the cooling water of the emulsification device to make the temperature of the emulsification device 35°C and add the water phase, the flow rate of the water phase is 0.10L / s, the shear rate of the emulsification device It is 2900r / min. After the water phase is added, the emulsification process starts, the flow rate is controlled to 0.5L / s, and the rotation speed of the emulsification device is 2900r / min. In...

Embodiment 2

[0044] Prepare 5 million ml egg drop syndrome oil emulsion inactivated vaccine.

[0045] 1.175 million ml of concentrated EDS antigen was inactivated and 75,000 ml of Tween-80 was added for use. Take 3.5336 million ml (density 0.818g / ml, 2890.5kg) of white oil, first add Span 80 185,600ml (density 0.994g / ml, 184.5kg), add 61.5kg of aluminum stearate, heat at 120°C and stir thoroughly until the solution is transparent. Add it to the first emulsification reaction kettle, when the temperature drops to 35°C, open the emulsification device, and at the same time turn on the cooling water of the emulsification device to make the temperature of the emulsification device 35°C and add the water phase, the flow rate of the water phase is 0.15L / s, the shear rate of the emulsification device It is 2900r / min. After adding the water phase, start the emulsification process, control the flow rate to 0.4L / s, and the rotation speed of the emulsification device to 2900r / min. In the first stage...

Embodiment 3

[0047] Prepare 5 million ml avian influenza oil emulsion inactivated vaccine.

[0048] 1.25 million ml of the concentrated avian influenza antigen was inactivated, and 805,000 ml of Tween was added for later use. Take 3.5336 million ml (density 0.818g / ml, 2890.5kg) of white oil, first add Span 80 185,600ml (density 0.994g / ml, 184.5kg), add 61.5kg of aluminum stearate, heat at 120°C and stir thoroughly until the solution is transparent. Add it to the first emulsification reaction kettle, when the temperature drops to 40°C, open the emulsification device, and at the same time turn on the cooling water of the emulsification device to make the temperature of the emulsification device 40°C and add the water phase, the flow rate of the water phase is 0.08L / s, the shear rate of the emulsification device It is 2900r / min. After adding the water phase, start the emulsification process, control the flow rate to 0.5L / s, and the emulsification device speed to 2900r / min. In the first sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com