Environment-friendly copper clad laminate and preparation method thereof

A copper-clad laminate, an environmentally friendly technology, applied in the field of copper-clad laminates, can solve the problems of phosphorus element environmental hazards and soil acidification, and achieve the effects of improved heat resistance and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

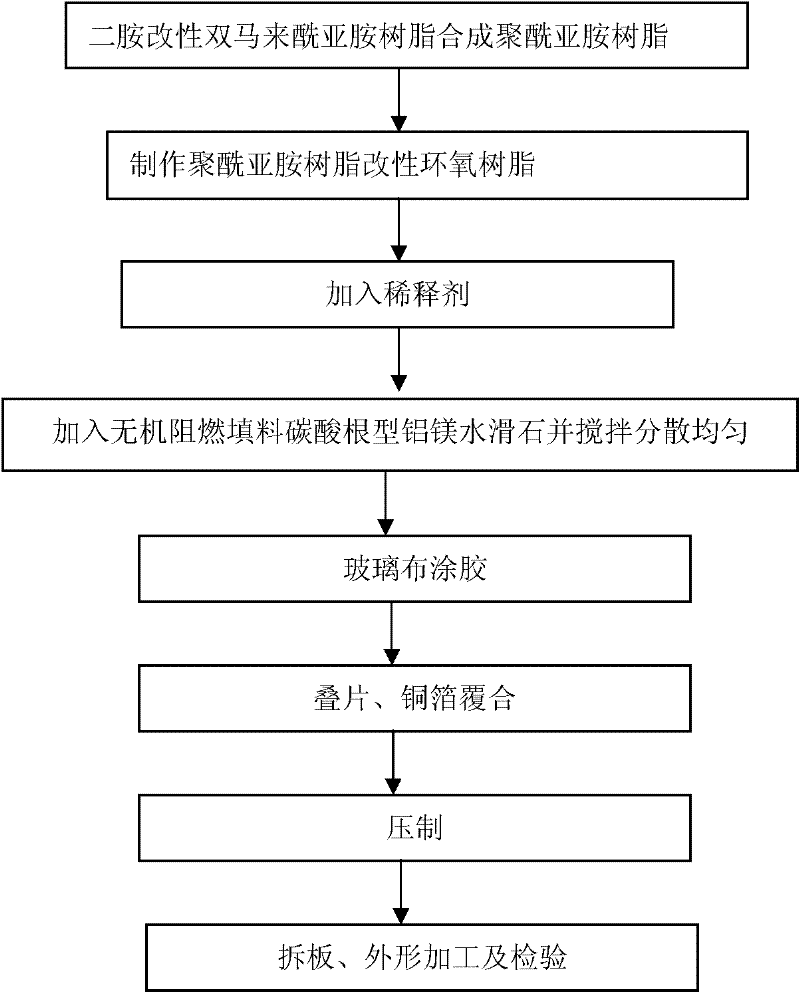

Method used

Image

Examples

Embodiment Construction

[0011] The gist of the present invention is to add more environmentally friendly and flame-retardant elements N and Al to the resin material used for copper-clad laminates, make them match in a certain proportion, and use their synergistic effects to achieve flame-retardant burning effect.

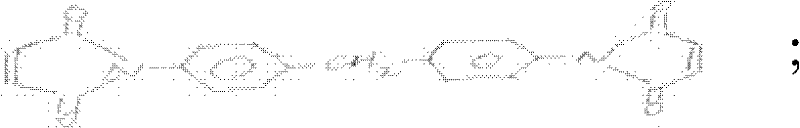

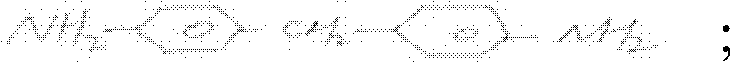

[0012] Based on the above ideas, the resin material in the copper-clad laminate provided in this embodiment selects polyimide resin to modify the epoxy resin, and then adds carbonate-type aluminum-magnesium hydrotalcite to form N, Al, Mg(OH) 2 Composite flame retardant system, while heat resistance is also strongly guaranteed.

[0013] Among them, polyimide resin has outstanding heat resistance, and contains N element, the N content is about 9.0%, and has certain flame retardancy. In addition, the carbonate-type aluminum magnesium hydrotalcite, referred to as LDHs, has a chemical formula: [Mg 6 Al 2 (OH) 16 CO 3 ]·4H 2 O, which contains Al and Mg hydrates, is also referred to as alum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap