Laser propulsion aircraft with vector nozzle

A vector nozzle and aircraft technology, applied in the direction of space vehicle propulsion system devices, etc., to achieve the effect of strong adaptability, low performance requirements, and good aerodynamic shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

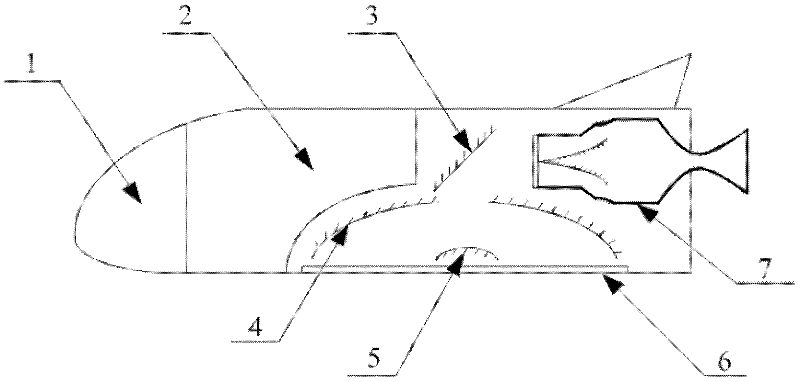

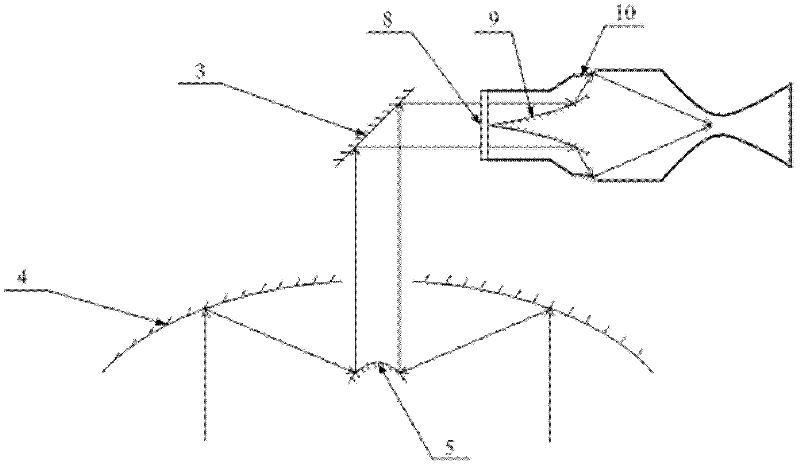

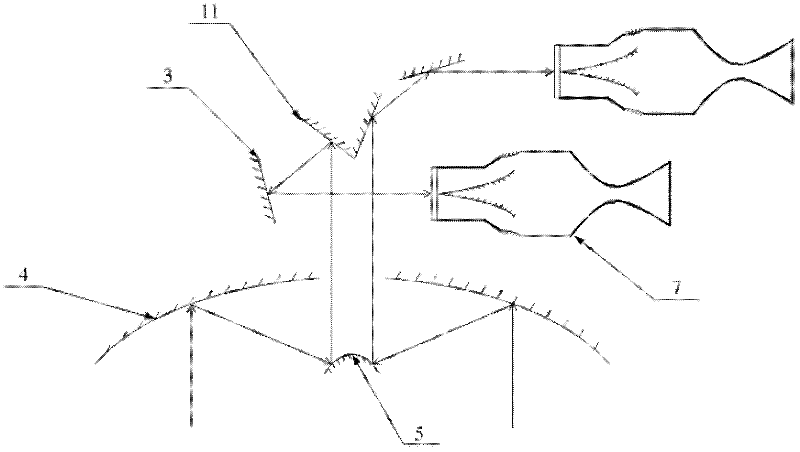

[0018] See attached Figure 1~3 , in this embodiment, the laser propulsion vehicle with the vector nozzle is powered by a 100MW ground-based laser, and can be launched from the ground into a low-earth orbit at an altitude of 200km. The aircraft is about 7m long, 3m wide, and 2m high. Its shape is similar to the US space shuttle orbiter, but the fuselage is slightly flat. The shell of the aircraft is made of high-strength aluminum-copper alloy. The propellant storage tank 2 is filled with liquid hydrogen as propellant, and the quality of liquid hydrogen accounts for about 60% to 70% of the total mass of the aircraft.

[0019] The diameter of the concave parabolic reflector 4 is about 1m, which is made of light weight and small deformation material, and the concave surface is coated with a high reflectivity film. The convex parabolic reflector 5 and the plane reflector 3 are made of materials with high reflectivity and fast heat dissipation, and a water-cooled active cooling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com