Method for synthesizing sodium diacetate crystal in one step

A technology of sodium diacetate and synthetic method, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of high raw material price, large reaction heat release, difficult process control, etc., and achieve reduced production cost, simple process and high product quality easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

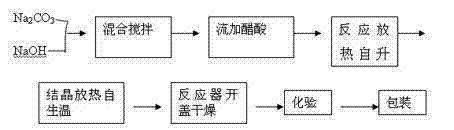

Method used

Image

Examples

Embodiment 1

[0020] raw material purity% mass kg % by weight glacial acetic acid 99% 100 70.68 ionic membrane bond 99% 15.5 10.95 Anhydrous sodium carbonate 99% 26 18.37

[0021] In the kneader, at room temperature, add ionic membrane and soda ash, turn on and stir to open the empty tube, add 100kg of glacial acetic acid dropwise in 17 minutes, and then automatically heat up to 85°C after 18 minutes, then automatically cool down slowly, and cool down in 15 minutes After 25 minutes, the temperature was lowered to 75°C, the lid of the reactor was opened, and the temperature was lowered to 50°C after 30 minutes for discharging.

[0022] Product sampling analysis: free acetic acid 39.9%, sodium acetate 58.8%, moisture 1.4%. Products comply with FAO / WHO standards.

Embodiment 2

[0024] raw material purity% mass kg % by weight glacial acetic acid 99% 78 72.2 ionic membrane bond 99% 12 11.1 Anhydrous sodium carbonate 99% 18 16.7

[0025] In the kneader, at room temperature, add ion membrane and soda ash, turn on and stir to open the empty tube, add the implemented amount of glacial acetic acid in 20 minutes, react for 10 minutes, after the temperature rises to 85 ℃, then automatically and slowly cool down, static After 15 minutes of crystallization, the temperature dropped to 80°C, and then the temperature was lowered to 60°C for 60 minutes before discharging.

[0026] Product sampling analysis: free acetic acid 40.4%, sodium acetate 58.3%, moisture 1.3% product. Compliant with FAO / WHO standards.

Embodiment 3

[0028] Keeping the raw material ratio of Example 1 unchanged, in the kneader, at room temperature, add ionic membrane and soda ash, turn on and stir to open the open tube, drop 100kg of glacial acetic acid in 10 minutes, and then automatically heat up to 65 ° C after 15 minutes. , and then automatically and slowly cool down to 60 °C in 5 minutes, open the lid of the reactor, and cool down to 50 °C after 15 minutes to discharge.

[0029] Product sampling analysis: free acetic acid 40.2%, sodium acetate 58.6%, moisture 1.2%. Products comply with FAO / WHO standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com