Ceramic precursor resin applicable to rainproof and self-cleaning coating of glass

A resin and glass surface technology, applied in the synthesis and application of functional polymers, can solve the problems of short service life and loss of effect of rainproof agents, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

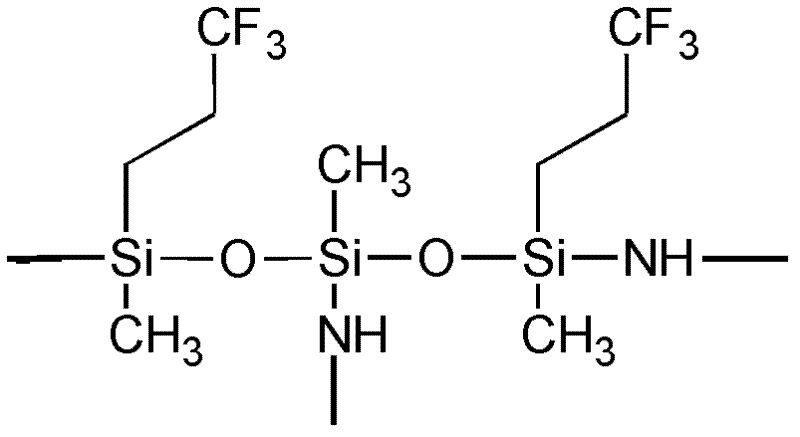

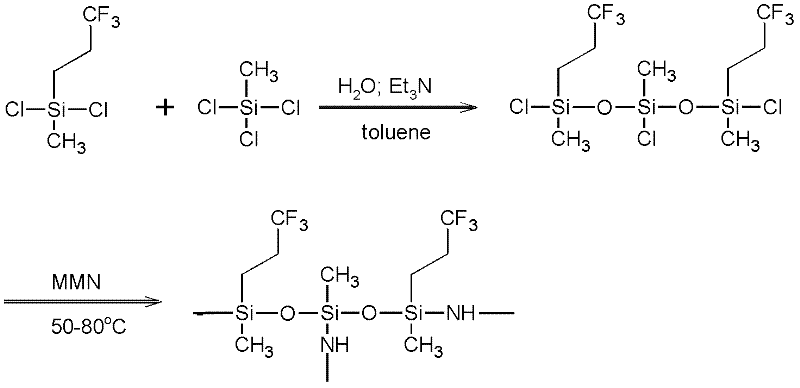

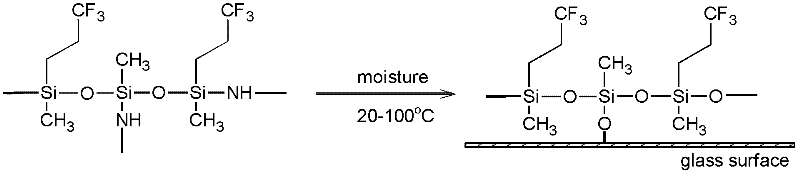

Method used

Image

Examples

Embodiment 1

[0037] In a 500mL glass bottle equipped with a reflux condenser (the upper end of the condenser is equipped with a continuous nitrogen protection device), a thermometer and an addition funnel, add 100mL of toluene, and add 21.1g (0.1mol) of trifluoropropylmethyl dichloride under stirring Silane and 7.5g (0.05mol) methyltrichlorosilane; then add 30g (0.3mol) triethylamine; add 1.8g (0.1mol) water dropwise under ice-bath conditions, react naturally for 3h to obtain a white cloudy solution.

[0038] 16 g (0.1 mol) of hexamethyldisilazane was added dropwise to the above solution, and heated to 60° C. for 16 hours to obtain a yellow turbid solution. After cooling to room temperature, filter online under the protection of nitrogen. The filtrate was evaporated to remove the solvent in vacuo to obtain a pale yellow viscose resin.

[0039] Due to its sensitivity to air and moisture, the resin should be stored in a nitrogen-protected container. The viscosity of the resin at room tempe...

Embodiment 2

[0041] As shown in Example 1, 100mL of toluene was added to a 500mL glass bottle, and 21.1g (0.1mol) of trifluoropropylmethyldichlorosilane, 6.5g (0.05mol) of dimethyldichlorosilane and 3g of (0.02mol) methyltrichlorosilane; then add 30g (0.3mol) triethylamine; add 1.8g (0.1mol) water dropwise under ice-bath conditions, react naturally for 3h to obtain a white turbid solution.

[0042] 17.6 g (0.11 mol) of hexamethyldisilazane was added dropwise to the above solution, and heated to 80° C. for 12 hours to obtain a yellow turbid solution. After cooling to room temperature, filter online under the protection of nitrogen. The filtrate was evaporated to remove the solvent in vacuo to obtain a pale yellow viscose resin. Gel permeation chromatography (GPC) test shows that the number average molecular weight of the resin is about 1300.

Embodiment 3

[0044] In a 500mL glass bottle equipped with a reflux condenser (the upper end of the condenser is equipped with a continuous nitrogen protection device), a thermometer and an addition funnel, add 100mL of toluene, and add 31.7g (0.15mol) of trifluoropropylmethyl dichloride under stirring Silane; add 20g (0.2mol) of triethylamine; add 1.08g (0.06mol) of water dropwise under ice-bath conditions, react naturally for 5h to obtain a white turbid solution.

[0045] 19.2 g (0.12 mol) of hexamethyldisilazane was added dropwise to the above solution, and heated to 60° C. for 24 hours to obtain a light yellow turbid solution. After cooling to room temperature, filter online under the protection of nitrogen. The filtrate was evaporated to remove the solvent in vacuo to obtain a pale yellow viscose resin. Gel permeation chromatography (GPC) test shows that the number average molecular weight of the resin is about 800.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com