Polyethylene terephthalate fiber-adding inflaming retarding material and preparation method thereof

A technology of polyethylene terephthalate and ethylene phthalate, which is applied in the field of polyethylene terephthalate fiber-reinforced flame retardant materials and their preparation, can solve the problem of inability to produce high-performance auxiliary materials. To solve the problems such as high requirements for chemical products, technical processing technology and poor fluidity, it can achieve the effect of low warpage, high surface finish and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

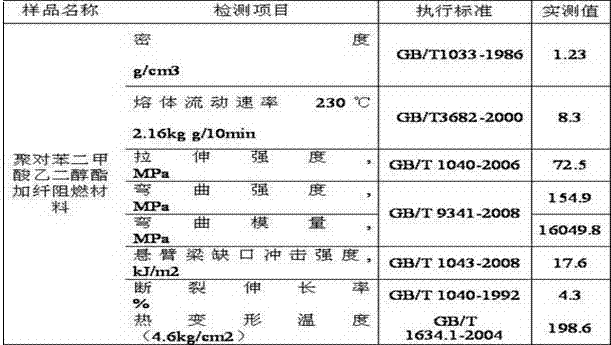

Image

Examples

Embodiment 1

[0026] Get 35 parts by weight of polyethylene terephthalate, 5 parts of toughening agent, 5 parts of fire retardant, 2 parts of montmorillonite, 0.8 part of polyethylene glycol glycidyl ether, through high-speed kneader Mix at 110°C for 15 minutes, and then granulate at 270°C through a twin-screw extruder. At the same time, 5 parts of glass fiber are added through the fiber-filling port to obtain polyethylene terephthalate fiber-added resistance. combustible material.

Embodiment 2

[0028] Take 60 parts of polyethylene terephthalate in parts by weight, 20 parts of maleic anhydride grafted styrene-butadiene rubber SBS, 15 parts of silicon nitrogen compounded halogen-free environmental protection flame retardant, 6000 mesh Mongolian 2 parts of soil removal, 0.8 parts of polyethylene glycol glycidyl ether, mixed by high-speed kneader at 90 ° C for 10 minutes, and then granulated at 240 ° C by twin-screw extrusion granulator, while 15 parts of glass fiber Add fiber through the port to make polyethylene terephthalate fiber reinforced flame retardant material.

Embodiment 3

[0030] Take 45 parts of polyethylene terephthalate in parts by weight, 15 parts of maleic anhydride grafted styrene-butadiene rubber SBS, 10 parts of silicon nitrogen compounded halogen-free environmental protection flame retardant, 6000 mesh Mongolian 2 parts of soil removal, 0.8 parts of polyethylene glycol glycidyl ether, mixed by high-speed kneader at 100 °C for 12 minutes, and then granulated at 250 °C by twin-screw extrusion granulator, and 10 parts of glass fiber Add fiber through the port to make polyethylene terephthalate fiber reinforced flame retardant material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com