Whey isolate protein-sodium caseinate composite edible film and preparation method thereof

The technology of whey protein isolate and sodium caseinate is applied in the field of food packaging materials and its preparation, which can solve the problems of poor gas and water vapor barrier properties and the like, and achieve the effects of good mechanical properties, easy storage and good heat-sealing properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

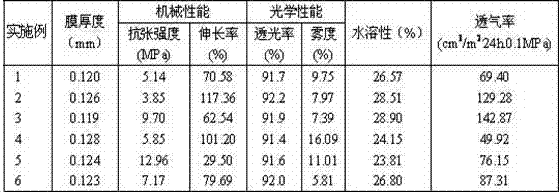

Examples

Embodiment 1

[0030] Preparation of whey protein isolate-sodium caseinate composite edible film (1)

[0031] (1) Weigh 2 g of whey protein isolate, add 98 g of deionized water, stir with a magnetic stirrer at 600 rpm for 2 hours to completely disperse the powder, and place the solution in a water bath at 80 °C for 40 minutes to denature the protein. The weight percent concentration of albumin isolate solution is 2%;

[0032] (2) Weigh 3g of sodium caseinate powder, add 97g of deionized water, stir with a magnetic stirrer at 600rpm for 2h to completely disperse the powder, and the prepared sodium caseinate solution has a weight percent concentration of 3%;

[0033] (3) After mixing the whey protein isolate solution in step (1) and the sodium caseinate solution in step (2), add 2 g of glycerol (that is, the weight of glycerol, which is the same as the weight of whey protein isolate and sodium caseinate) The percentage of the sum is 40%) and evenly mixed to obtain a film-forming solution; ...

Embodiment 2

[0036] Preparation of whey protein isolate-sodium caseinate composite edible film (2)

[0037] (1) Weigh 3 g of whey protein isolate, add 97 g of deionized water, stir with a magnetic stirrer at 600 rpm for 2 hours to completely disperse the powder, and place the solution in a water bath at 85°C for 20 minutes to denature the protein. The weight percent concentration of albumin isolate solution is 3%;

[0038] (2) Weigh 5g of sodium caseinate powder, add 95g of deionized water, stir with a magnetic stirrer at 600rpm for 2h to completely disperse the powder, and the prepared sodium caseinate solution has a weight percent concentration of 5%;

[0039] (3) After all the whey protein isolate solution in step (1) and the sodium caseinate solution in step (2) are all mixed, 4.4 g of glycerol (that is, the weight of glycerol, which is combined with whey protein isolate and sodium caseinate) is added. The percentage of the sum of the weight is 55%) and evenly mixed to obtain a film...

Embodiment 3

[0042] Preparation of whey protein isolate-sodium caseinate composite edible film (3)

[0043] (1) Weigh 4g of whey protein isolate, add 96g of deionized water, stir with a magnetic stirrer at 600 rpm for 2 hours to completely disperse the powder, and place the solution in a water bath at 80°C for 30 minutes to denature the protein. The weight percent concentration of albumin isolate solution is 4%;

[0044] (2) Weigh 7g of sodium caseinate powder, add 93g of deionized water, stir with a magnetic stirrer at 600rpm for 2h to completely disperse the powder, and the prepared sodium caseinate solution has a weight percent concentration of 7%;

[0045] (3) After all the whey protein isolate solution in step (1) and the sodium caseinate solution in step (2) are all mixed, 3.85 g of glycerol (that is, the weight of glycerol, which is mixed with whey protein isolate and sodium caseinate) is added. The percentage of the sum of the weight is 35%) and evenly mixed to obtain a film-for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com