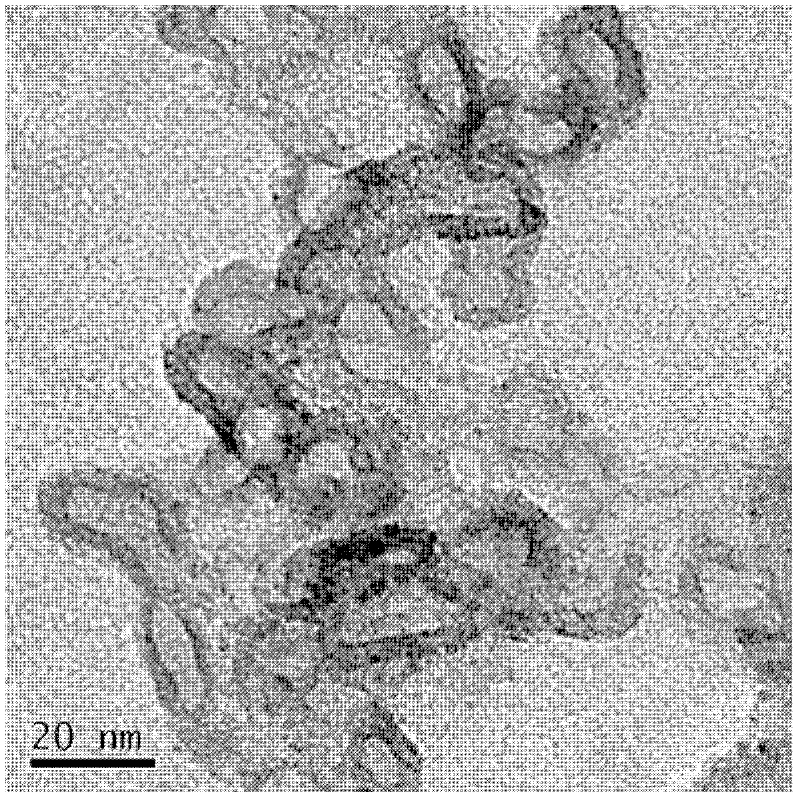

Quantum dot-polyelectrolyte fluorescent nano complex and application thereof

A polyelectrolyte and fluorescent nanotechnology, which is applied in the field of nanomaterials, can solve the problems of sulfhydryl ligands falling off easily, reducing the fluorescence quantum yield of quantum dots, etc., and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

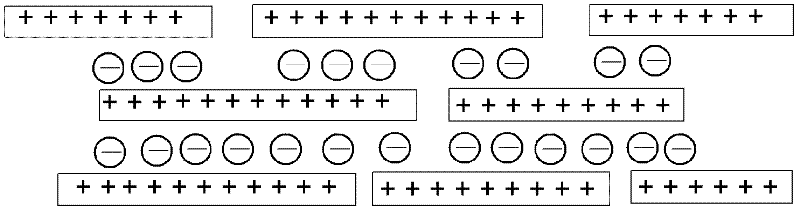

Embodiment 1

[0049] Take 1ml of the prepared CdTe quantum dot stock solution and place it in an ampoule, add 300μL of 30mg / ml PDADMAC, stir magnetically for 20-30min, add a mixed solution of acetone and absolute ethanol with a volume ratio of 1:1 until the solution is slightly cloudy ( The volume ratio of the reaction solution to the precipitation reagent is about 1:2.5), after shaking evenly, centrifuge at 12,000 rpm for 15 minutes to remove excess PDADMAC, after the centrifugation is complete, discard the supernatant, wash the precipitate twice with three distilled water, The precipitate was ultrasonically redissolved in 1ml triple distilled water to obtain the CdTe-PDADMAC stock solution.

Embodiment 2

[0051] Take 1ml of the prepared CdTe / CdS quantum dot stock solution and place it in an ampoule, add 300μL of 30mg / ml PDADMAC, stir magnetically for 20-30min, add a mixed solution of acetone and absolute ethanol with a volume ratio of 1:1 until the solution is slightly Turbidity (the volume ratio of the reaction solution to the precipitation reagent is about 1:2.5), shake evenly, and centrifuge at 12000rpm for 15 minutes to remove excess PDADMAC. After the centrifugation is complete, discard the supernatant and wash the precipitate twice with three distilled water , ultrasonically redissolve the precipitate in 1ml triple distilled water to obtain the CdTe / CdS-PDADMAC stock solution.

Embodiment 3

[0053] Take 1ml of the prepared CdTe quantum dot stock solution and place it in an ampoule, add 12mg / ml cationic polyelectrolyte PDADMAC monomer DADMAC 200μL, stir magnetically for 20min, then add 10mg / ml polyelectrolyte adjusted to pH=7 with sodium hydroxide. Acrylic acid 200 μL, magnetically stirred for 20 minutes, using a mixed solution of acetone and absolute ethanol with a volume ratio of 1:1 as the precipitation reagent, until the solution was slightly turbid (the volume ratio of the reaction solution to the precipitation reagent was about 1:10), after shaking evenly , 12000rpm high-speed centrifugation for 20min to remove excess DADMAC monomer and PAA. After the centrifugation is complete, discard the supernatant, wash the precipitate twice with triple distilled water, and ultrasonically re-dissolve the precipitate in 1ml triple distilled water to obtain CdTe-DADMAC - PAA stock solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com