Method for preparing biodiesel by catalysis of rare-earth oxide mesoporous material

A rare earth oxide and biodiesel technology, applied in renewable energy and green fields, can solve problems such as pretreatment catalyst separation difficulties, large amounts of industrial wastewater, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

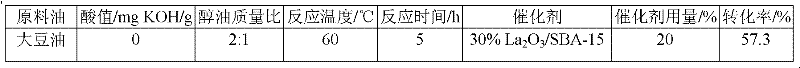

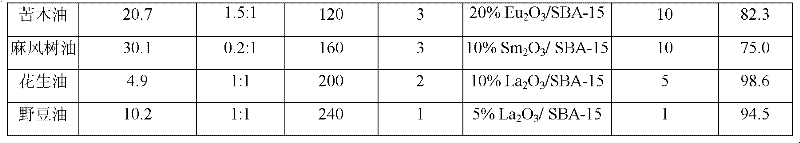

Embodiment 1

[0020] In a 100 ml autoclave, add 20 grams of refined soybean oil, 40 grams of methanol, and 4 grams of 30% La 2 o 3 / SBA-15 catalyst, the reaction temperature is controlled at 60°C, the mechanical stirring speed is 600rpm, and the reaction time is 5 hours; after the reaction is completed, the catalyst is separated by suction filtration while it is hot, the methanol is recovered by distillation, and then the filtrate is allowed to stand overnight to separate layers. The product in the upper layer is biodiesel, and the lower layer is glycerin; the yield of the obtained biodiesel is 57.3% as detected by liquid chromatography.

Embodiment 2

[0022] In a 100 ml autoclave, add 20 grams of bitter wood oil, 30 grams of methanol, and then add 2 g of 20% Eu 2 o 3 / SBA-15 catalyst, the reaction temperature is controlled at 120°C, the mechanical stirring speed is 600rpm, and the reaction time is 3 hours; after the reaction is completed, it is suction filtered while it is hot, the catalyst is separated, methanol is recovered by distillation, and then the filtrate is allowed to stand overnight for stratification; the upper layer The product is biodiesel, and the lower layer is glycerin. Detected by liquid chromatography, the yield of biodiesel obtained was 82.3%.

Embodiment 3

[0024] In a 100 milliliter autoclave, add 20 grams of jatropha oil, 4 grams of methanol, and then add 2 grams of 10% Sm 2 o 3 / SBA-15 catalyst, the reaction temperature is controlled at 160°C, the magnetic stirring speed is 600rpm, and the reaction time is 3 hours; after the reaction is completed, the catalyst is separated by suction filtration while it is hot, and the methanol is recovered by distillation, and then the filtrate is allowed to stand overnight for stratification; the upper layer The product is biodiesel, and the lower layer is glycerin. Detected by liquid chromatography, the yield of biodiesel obtained was 75.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com