Circuit connecting material, film-like circuit connecting material using the circuit connecting material, structure for connecting circuit member, and method for connecting circuit member

A circuit connection material and circuit technology, applied in conductive materials dispersed in non-conductive inorganic materials, printed circuit components, structural connection of printed circuits, etc., can solve problems such as short circuits, and ensure continuity and excellent connection. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0165]

[0166] [Production of conductive fine particles]

[0167] The scaly silver powder 1 having a particle size distribution of 0.005 to 10 μm was obtained by chemical reduction. The obtained silver powder 1 was classified to obtain a scaly silver powder 2 having an average particle diameter of 0.25 μm and a maximum particle diameter of 0.4 μm.

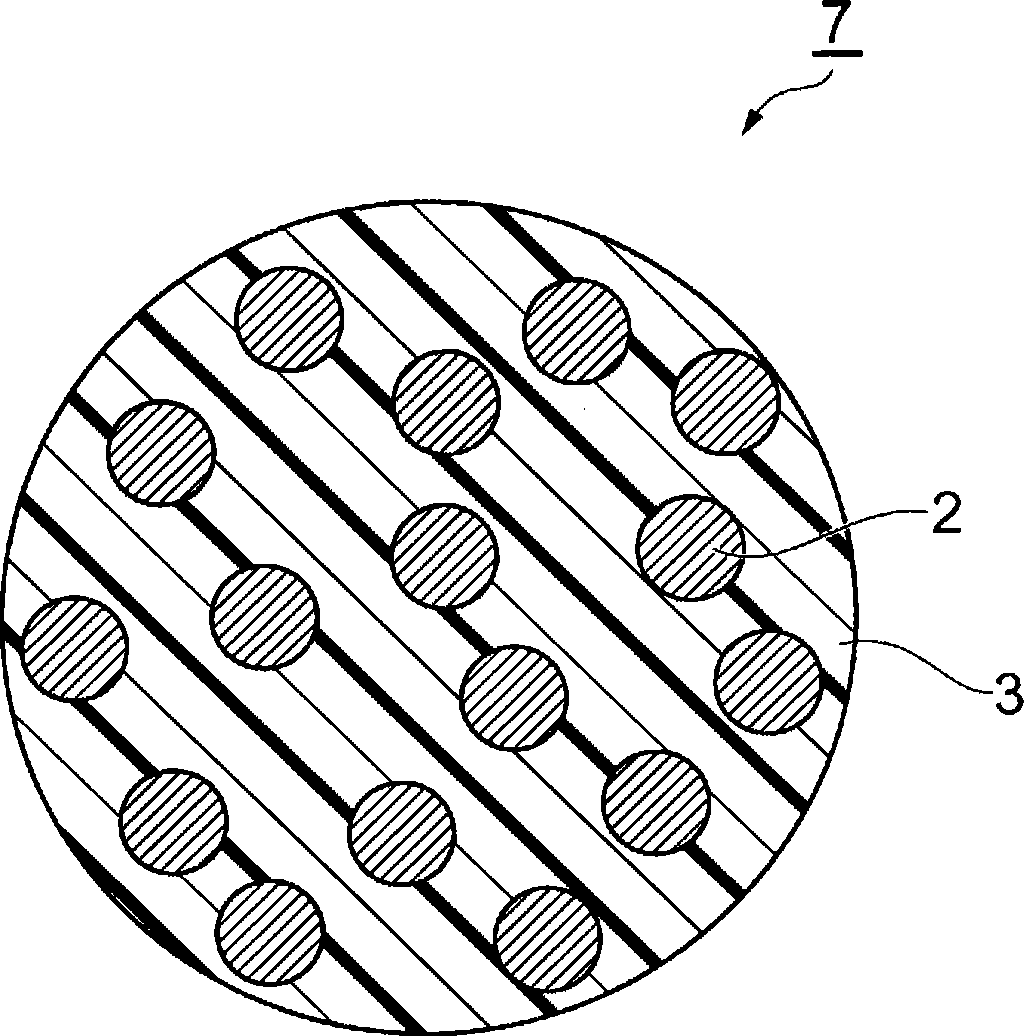

[0168] [Production of anisotropic conductive particles]

[0169] 60 parts by mass of tetramethylolmethane triacrylate, 20 parts by mass of divinylbenzene, and 20 parts by mass of acrylonitrile were mixed as raw material monomers of the organic insulating substance. Further, 120 parts by volume of silver powder 2 was added to 100 parts by volume of the raw material monomer of the organic insulating material, and the silver powder was dispersed for 48 hours using a bead mill. In the composition dispersed with this silver powder, mix 2 mass parts of benzoyl peroxide, and drop it into 850 mass parts of polyvinyl alcohol aqueous so...

manufacture example 2

[0170]

[0171] The silver powder 2 that makes in the manufacture example 1 is immersed in the solution that 3 mass parts N-(2-aminoethyl)-3-aminopropyltrimethoxysilane is dissolved in the solution in 100 mass parts methyl ethyl ketone, stirs 1 day and night, thereby Hydrophobizing the surface of silver powder. Except having used the silver powder whose surface was hydrophobized, it carried out similarly to the said manufacture example 1, and obtained the anisotropic electrically-conductive particle 2.

manufacture example 3

[0172]

[0173] The anisotropic conductive particles produced in Production Example 1 were classified to obtain anisotropic conductive particles 3 with an average particle diameter of 0.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com