Preparation method of acid-soluble soybean protein

A soybean protein and acid-soluble technology, applied in the field of preparation of acid-soluble soybean protein, can solve the problems of affecting the taste of food, causing diarrhea, not obtaining soybean protein, etc., achieving obvious solubilization effect, improving solubility, and simple implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

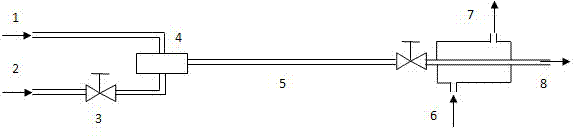

Image

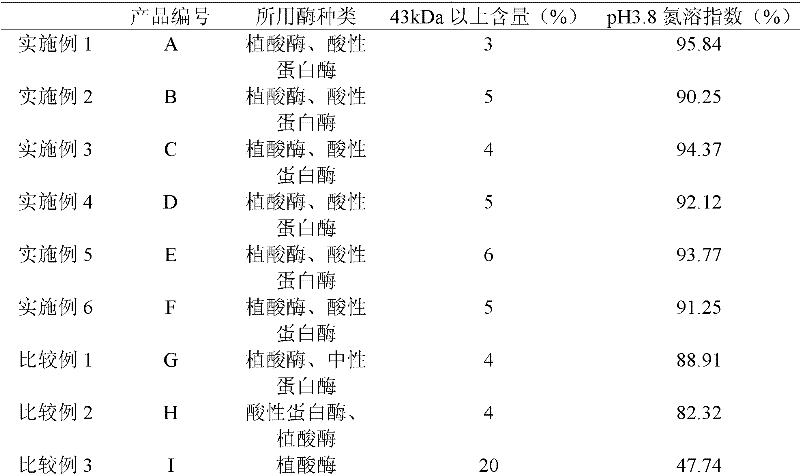

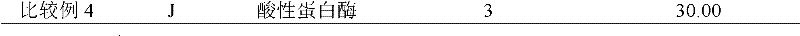

Examples

Embodiment 1

[0030] The soybean defatted soybean meal (NSI=85) extracted by n-hexane extraction method was crushed and passed through a 60-mesh sieve to obtain defatted soybean powder, mixed with water according to the mass ratio of 1:15, stirred at room temperature for 1 hour, and mixed with 2mol / L Adjust the pH to 8.0 with NaOH, and then centrifuge at 3000rpm for 20min. Take the supernatant and use 2mol / L HCL to adjust the pH to 4.5, centrifuge at 3000rpm for 20min to obtain the soybean protein precipitate, dissolve the protein precipitate with deionized water according to the solid-liquid mass ratio of 1:10, and constantly adjust the pH to 4.5 with 2mol / L NaOH. 7.0 to obtain soybean protein extract.

[0031] Dilute the soybean protein extract to 5% protein concentration with deionized water, adjust the pH to 5.5 with 2mol / L HCL, and add 30U of phytase (Phytase, Huayang) to enzymatically hydrolyze each g of protein at 37°C 30min, then use 2mol / L HCL to adjust the pH to 4.0, add 2g acid ...

Embodiment 2

[0033]Grind soybean defatted soybean meal (NSI=60) obtained by pressing and pass through a 60-mesh sieve to obtain defatted soybean powder, mix it with water at a mass ratio of 1:15, stir at room temperature for 1 hour, and continuously use 2mol / L NaOH Adjust the pH to 8.0, then centrifuge at 3000rpm for 20min. Take the supernatant and use 2mol / L HCL to adjust the pH to 4.5, centrifuge at 3000rpm for 20min to obtain the soybean protein precipitate, dissolve the protein precipitate with deionized water according to the solid-liquid mass ratio of 1:10, and constantly adjust the pH to 4.5 with 2mol / L NaOH. 7.0 to obtain soybean protein extract.

[0034] Dilute the soybean protein extract to 5% protein concentration with deionized water, adjust the pH to 5.5 with 2mol / L HCL, and add 30U of phytase (Phytase, Huayang) to enzymatically hydrolyze each g of protein at 37°C 30min, then use 2mol / L HCL to adjust the pH to 4.0, add 2g acid protease (NovoCorAB, Novozymes) at 37°C for 30min...

Embodiment 3

[0036] The soybean defatted soybean meal (NSI=88) extracted by n-hexane extraction method was pulverized and passed through a 60-mesh sieve to obtain defatted soybean powder, mixed with water at a mass ratio of 1:15, stirred at a medium speed at room temperature for 1 hour, and continuously used 2mol / L The pH was adjusted to 8.0 with NaOH, and then centrifuged at 1000rpm for 20min. Take the supernatant and adjust the pH to 4.5 with 2mol / L HCL, centrifuge at 1000rpm for 20min to obtain the soybean protein precipitate, dissolve the protein precipitate with deionized water according to the solid-to-liquid mass ratio of 1:10, and constantly adjust the pH to 4.5 with 2mol / L NaOH. 7.0 to obtain soybean protein extract.

[0037] Dilute the soybean protein extract to 5% protein concentration with deionized water, adjust the pH to 5.5 with 2mol / L HCL, and add 300U of phytase (Phytase, Huayang) to enzymatically hydrolyze each g of protein at 20°C 50min, then adjust the pH to 4.0 with 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com