A Dissimilar Metal Composite Piston Forging Technology

A dissimilar metal and forging technology, applied in the field of solid-state hot die forging, can solve the problems of weak push-pull strength of internal threads, achieve good machining performance, reduce product costs, and save copper alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

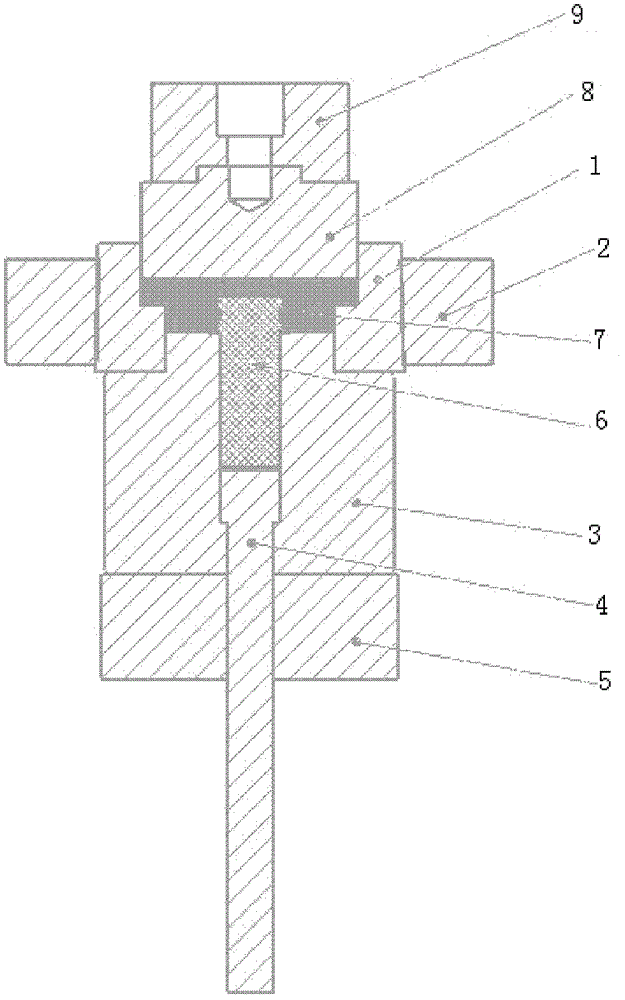

[0030] The forging process of copper alloy and steel composite piston specifically includes the following steps:

[0031] a. Material preparation: unloading on the band sawing machine, sawing the copper alloy and steel into the required length and weight;

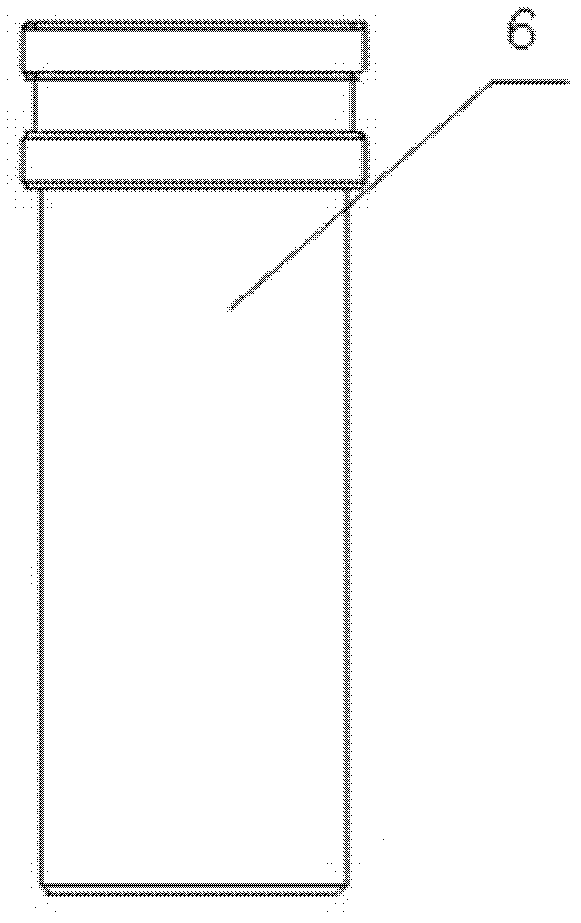

[0032] b. Machining: the sawed steel bar material such as figure 1 Surface processing is performed as shown, specifically, the sawn steel material is firstly turned to the light at one end, and then turned into a process groove, the flat end surface of the inverted head is determined to have a total length and turned into an outer circle, and the end with the groove is kept clean;

[0033] c. Forging preparation: match the number of sawn copper alloy materials and machined steel parts one-to-one, put the copper alloy materials into the box furnace and place them neatly, and control the heating temperature to 760°C; forge the piston The special convex and concave molds are respectively installed on the upper and lower workt...

Embodiment 2

[0039] The forging process of the aluminum alloy and steel composite piston, the specific steps are equal to the first embodiment, only the heating temperature of the aluminum alloy material in the box furnace is adjusted to 470 ° C, the mold is preheated to 300 ° C, the forging process The steps are consistent with those in Example 1. The composite piston head is made of non-ferrous metal aluminum alloy, and the piston rod is made of 45 steel. The tensile strength of aluminum alloy is 345, and the Brinell hardness is lower than that of copper alloy; the tensile strength of steel is 593, and the Brinell hardness is HB229. From the comparison of the two sets of mechanical property data of the above two materials, it can be clearly seen that the piston rod made of steel is better than the aluminum alloy in terms of strength. Since the mechanical properties of the forged composite piston, the tensile strength is not less than 345, Therefore, the mechanical performance and reliab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com