Electrophoretic deposition preparation method for V2O5 film

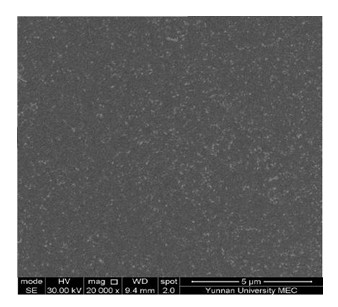

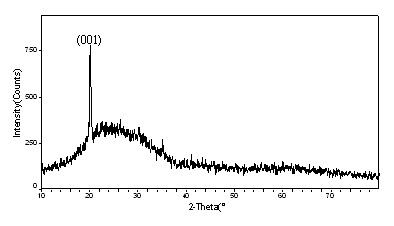

A technology of electrophoretic deposition and V2O5, which is applied in the direction of electrophoretic plating, electrolytic coating, coating, etc., can solve the problems of complex preparation process and unstable film, and achieve the effect of simple process, dense and uniform structure, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

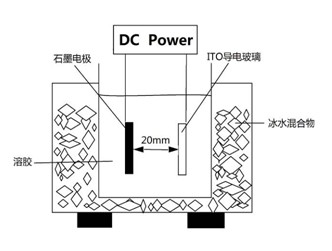

[0028] (1) To analyze pure V 2 o 5 As raw material, the concentration is 25wt% H 2 o 2 For the reaction solvent, according to V 2 o 5 :H 2 o 2 =1g:50mL of the solution configured in the ratio, and then under the condition of keeping the temperature at -2oC all the time, using electromagnetic stirring at a stirring rate of 3 rev / s, to H 2 o 2 Add 0.05 g of V every 20 seconds to the solvent 2 o 5 powder, the solution is light yellow, with V 2 o 5 Add the powder while stirring continuously, the color of the solution gradually becomes darker until it is a reddish-brown solution, and then stir for 10 minutes to obtain a transparent solution without precipitation; then put it on an ultrasonic cleaner, use 80KHz ultrasonic waves to continue stirring, Keep the temperature at -2 oC to promote grain refinement and make the solution more uniform. After stirring for 10 minutes, the precursor solution is obtained after filtration. The prepared precursor solution is sealed and st...

Embodiment 2

[0032] (1) To analyze pure V 2 o 5 As raw material, the concentration is 20wt% H 2 o 2 For the reaction solvent, according to V 2 o 5 :H 2 o 2 =0.6g:30mL ratio configuration solution, then under the condition that the temperature is kept at 0oC all the time, using electromagnetic stirring at a stirring rate of 1 rev / s, to H 2 o 2 Add 0.1 g of V every 30 seconds to the solvent 2 o 5 powder, the solution is light yellow, with V 2 o 5 Add the powder while stirring continuously, the color of the solution gradually becomes darker until it is a reddish-brown solution, and then stir for 20 minutes to obtain a transparent solution without precipitation; then put it on an ultrasonic cleaner, use 20KHz ultrasonic waves to continue stirring, Keep the temperature at 0oC to promote grain refinement and make the solution mix more evenly. After stirring for 15 minutes, the precursor solution is obtained after filtration, and the prepared precursor solution is sealed and stored at ...

Embodiment 3

[0036] (1) To analyze pure V 2 o 5 As raw material, the concentration is 40wt% H 2 o 2 For the reaction solvent, according to V 2 o 5 :H 2 o 2 =1.5g:90mL ratio configuration solution, then under the condition that the temperature is kept at 1oC all the time, using electromagnetic stirring at a stirring rate of 5 rev / s, to H 2 o 2 Add 0.08 g of V every 40 sec to the solvent 2 o 5 powder, the solution is light yellow, with V 2 o 5 Add the powder while stirring continuously, the color of the solution gradually becomes darker until it is a reddish-brown solution, and then stir for 30 minutes to obtain a transparent solution without precipitation; then put it on an ultrasonic cleaner, use 100KHz ultrasonic waves to continue stirring, Keep the temperature at 1oC to promote grain refinement and make the solution mix more evenly. After stirring for 30 minutes, the precursor solution is obtained after filtration, and the prepared precursor solution is sealed and stored at 1o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com