High-pressure electric fuel gas injection single ceramic combustion chamber of diesel engine

A high-pressure gas chamber and combustion chamber technology, which is applied to combustion engines, mechanical equipment, machines/engines, etc., can solve the problems of difficult ceramic engine processing technology and difficult realization, so as to improve work efficiency, save electric energy, and increase temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

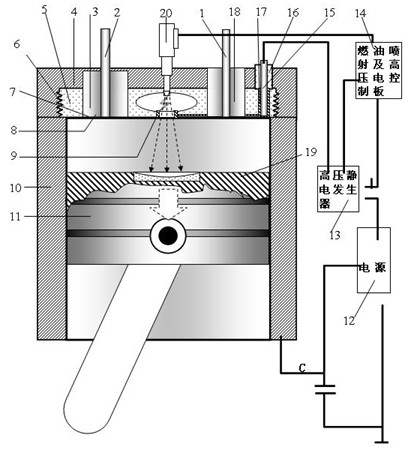

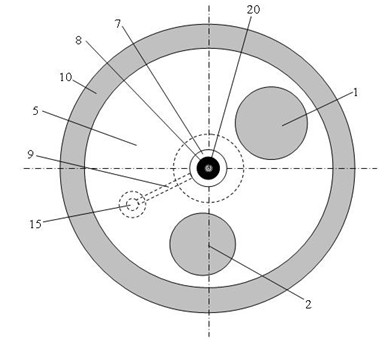

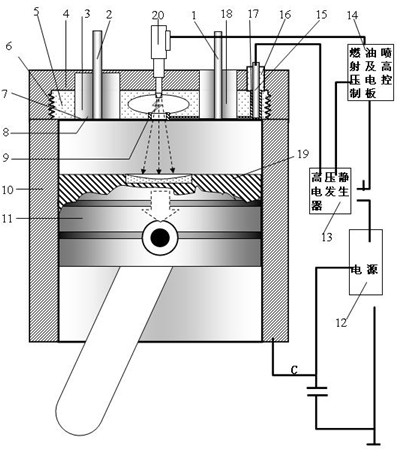

[0014] Embodiment 1: A diesel engine high-voltage electric gas injection single ceramic combustion chamber, including ceramic combustion chamber 5, ceramic high-pressure gas chamber 3, fastening rib 6, metal discharge ring 7, gas injection hole 8, conductive metal strip 9, metal Conductive rod 15, high-pressure diesel nozzle 20, concave ceramic sheet 19, high-voltage electrostatic generator 13, fuel injection and high-voltage electric control board 14. The ceramic combustion chamber 5 is embedded in the metal cylinder head 4 through the fastening thread 6 , and a ceramic high-pressure air chamber 3 is arranged in the ceramic combustion chamber 5 . The ceramic high-pressure air chamber 3 is an ellipsoid cavity, the top of the ceramic high-pressure air chamber 3 is equipped with a high-pressure diesel nozzle 20, the metal cylinder head 4 itself is a negative ground, and the high-pressure diesel nozzle 20 is connected with the metal cylinder head 4, so that the high-pressure diese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com