Plate type solar heat insulation polyester cotton and processing technology thereof

A technology of heat insulation and processing technology, applied in the field of fiber cotton, can solve problems such as pollution and harm, and achieve the effect of preventing thermal energy radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be further described below in conjunction with specific processing techniques.

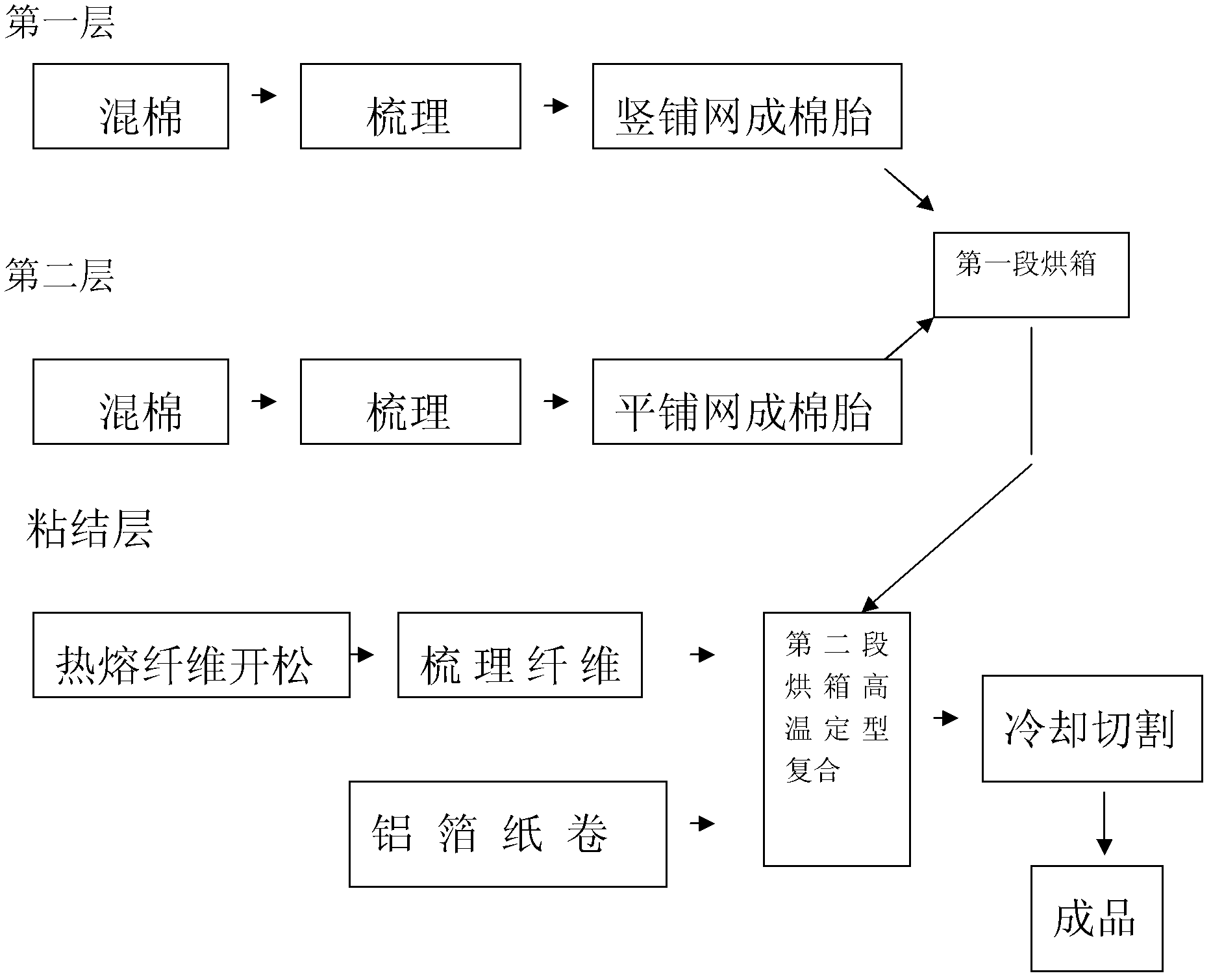

[0029] like figure 2 Shown, the processing technique of the embodiment of the present invention is:

[0030] The first step: the preparation of insulation batt

[0031] Take the hot-melt fiber of specification 4D*51MM*SD and type SN-3459CM produced by Korean HUVIS (Huvis) manufacturer, and the specification 7D*64MM*SD and type SN-3760CHB produced by Yuanfang Industry (Shanghai) Co., Ltd. Functional fiber, according to the weight ratio of 15:85, the wool is opened, loosened and mixed with cotton evenly. After being combed by a carding machine, it becomes a net-like wadding, and the insulation wadding of a square meter with a uniform thickness and a weight of 300-1500G is laid by vertical laying. batting;

[0032] The second step: preparation of strong cotton batting

[0033] In the same way, take the hot-melt fiber and functional fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com