Inner-fluorin and outer-silicon tube with fire resistance, high and low temperature resistance and oil resistance and preparation method thereof

A technology of high and low temperature resistance, silicone tube, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problem of no flame retardancy, etc., and achieve the effect of excellent high and low temperature resistance and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

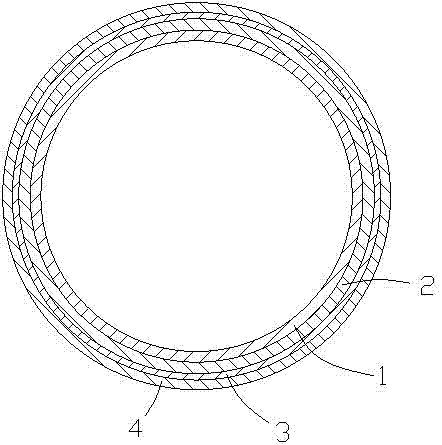

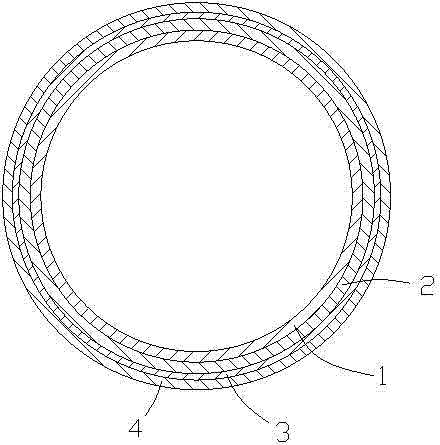

[0038] Such as figure 1 As shown, the present invention has a flame-retardant, high and low temperature resistant, oil-resistant fluorine inner and outer silicone tube, which includes an inner rubber layer 1, a middle rubber layer 2, a skeleton layer 3 and an outer rubber layer 4 from the inside to the outside.

[0039] The raw materials of the inner rubber layer 1, the middle rubber layer 2, the skeleton layer 3 and the outer rubber layer 4, and their component weight ratios are:

[0040] Inner rubber layer 1: Fluorosilicone rubber: 80-120 Gas-phase method silicone rubber: 10-30

[0041] Defrost agent: 0.5-1 Vulcanizing agent: 1-2

[0042] Ferric oxide: 1-3 PTFE: 2-5

[0043] Antimony trioxide: 3-6 3.5H 2 O zinc borate: 8-15

[0044] Silazane: 1-3 Decabromodiphenyl ether: 7-15

[0045] Fumed silica: 3-6 Color masterbatch: 1-2;

[0046] Middle rubber layer 2: Fluorosilicone rubber: 20-70 gas-phase method silicone rubber 50-80

[0047] Masterbatch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com