Multistage continuous overheated steam drying system and method of low-rank coal

A technology of superheated steam and drying system, applied in heating to dry solid materials, drying solid materials, drying, etc., can solve the problems of high power consumption and maintenance costs, high dust, small drying capacity, etc., to improve the processing capacity and Drying efficiency, simple drying process, and the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

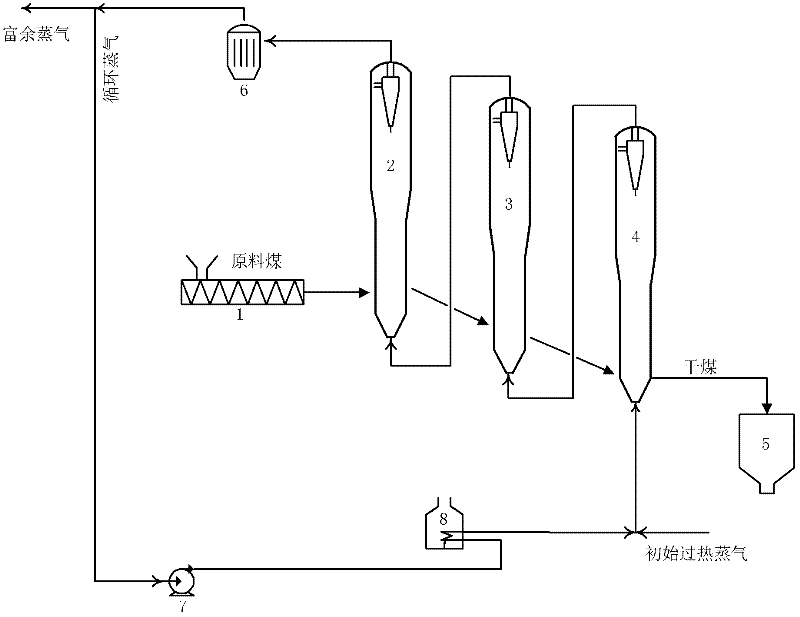

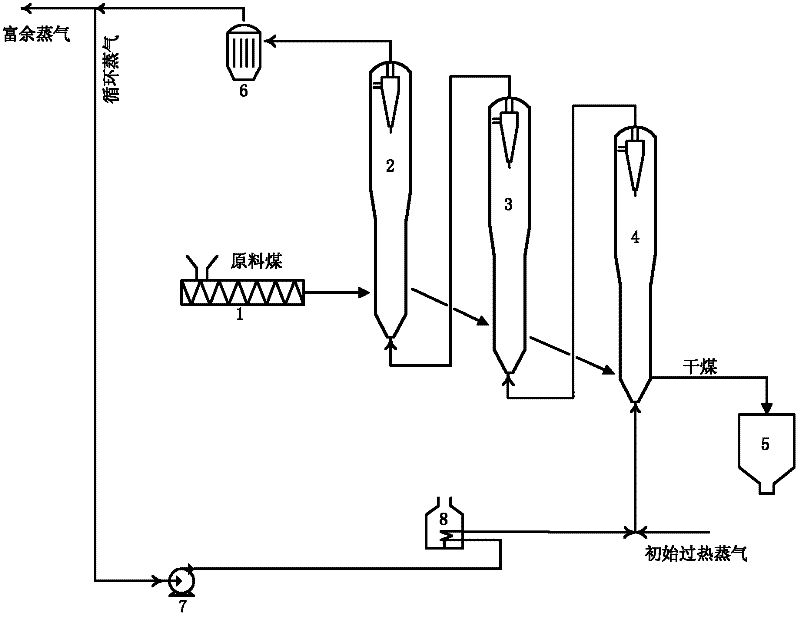

[0036] In this example, the average particle size is 2.0mm, the initial moisture content is 60%, and the outlet dry coal moisture content is required to be controlled below 10% for example, and the multi-stage continuous drying process of low-rank coal superheated steam is described.

[0037] 1) Primary drying process: the lignite with an average particle size of 2.0mm and an initial moisture content of 60% is transported to the primary fluidized bed drying device (2) by the raw coal feeding device (1). Using the superheated steam with a temperature of 100-200°C discharged from the secondary fluidized bed drying device (3) as the drying medium, the raw coal is stably fluidized in the fluidized bed, heat exchange is performed between the steam and the coal, and part of the water is vaporized. When the lignite is dried to a moisture content of <35%, it is sent to a secondary fluidized bed drying device (3) for secondary drying. After the steam discharged from the first-stage flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com