Enteromorpha flocculant and preparation process thereof

The technology of flocculant and prolifera is applied in the field of flocculant and its preparation, which can solve the problems of consuming financial resources and the like, and achieve the effects of diversified structure, simple production process and strong applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The Enteromorpha used in this example was taken from Qingdao No. 1 Bathing Beach, the Enteromorpha was washed, dried in an oven at 70°C, then pulverized into powder in a magnetic pulverizer, and passed through a 100-mesh sieve to obtain a dry sample of Enteromorpha. The dry sample of Enteromorpha and deionized water were mixed at a mass ratio of 1:75, and stirred and leached in a constant temperature water bath at 90°C for 4 hours. The leached solution was centrifuged in a high-speed centrifuge at a speed of 5000r / min for 20 minutes. After taking the supernatant and adding the same volume of deionized water to dilute, the yellow-green transparent liquid is obtained, which is Enteromorpha flocculant.

[0021] The Enteromorpha flocculant of Example 1 was used to treat simulated water samples and actual water samples in the water treatment process, as detailed below.

[0022] Experimental water sample:

[0023] There are two kinds of water samples used in the experiment: one is ...

experiment example 1

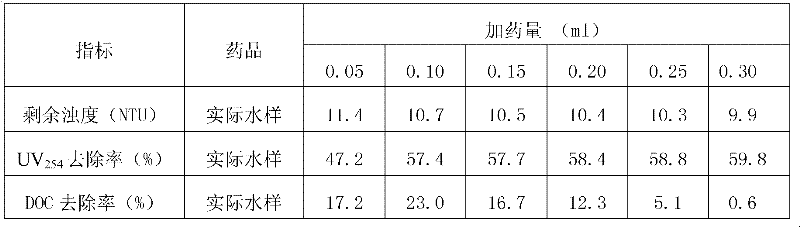

[0025] The Enteromorpha flocculant prepared in Example 1 was used for the coagulation treatment of humic acid-kaolin simulated water samples. The results are listed in Table 1. The raw water quality is as follows: pH value is 8.37-8.4, turbidity is 15.1-15.4 NTU , UV 254 0.289-0.295cm -1 , DOC is 4.948-5.116mg / L.

[0026] Table 1 The effect of Enteromorpha flocculant on humic acid-kaolin simulated water samples

[0027]

[0028] From the above treatment results, it can be seen that the humic acid-kaolin simulated water sample treated with Enteromorpha flocculant has a significant effect on turbidity and UV 254 The removal effect of Enteromorpha is better, and the removal effect of DOC is average. Because Enteromorpha is an organic matter, when the dosage of Enteromorpha is more than 0.1mL, the removal efficiency of DOC gradually decreases and reaches the maximum value at 0.1mL.

experiment example 2

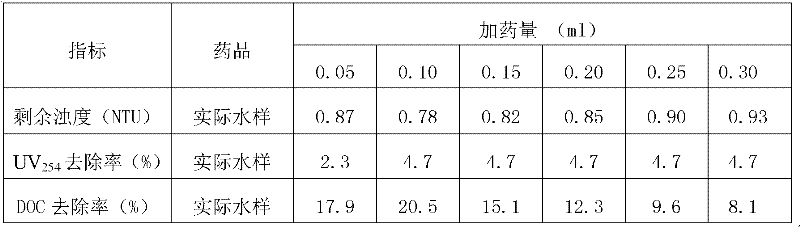

[0030] The Enteromorpha flocculant prepared in Example 1 was used for the coagulation treatment of the actual water samples of the Yellow River Diversion Reservoir. The raw water quality is as follows: pH value is 8.41-8.45, turbidity is 4.35-4.60 NTU, UV 254 0.036-0.040cm -1 , DOC is 3.688-3.787mg / L. The treatment results are listed in Table 2.

[0031] Table 2 The effect of Enteromorpha flocculant on actual water samples from the Yellow River Diversion Reservoir

[0032]

[0033] From the above treatment results, it can be seen that the treatment of the actual water samples of Enteromorpha flocculant for the removal of turbidity and DOC is better. When the dosage of Enteromorpha is greater than 0.1mL, the removal efficiency of DOC gradually decreases, at 0.1mL The best removal effect can reach 20%, and Enteromorpha flocculant is better for UV 254 The removal effect is not very satisfactory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com