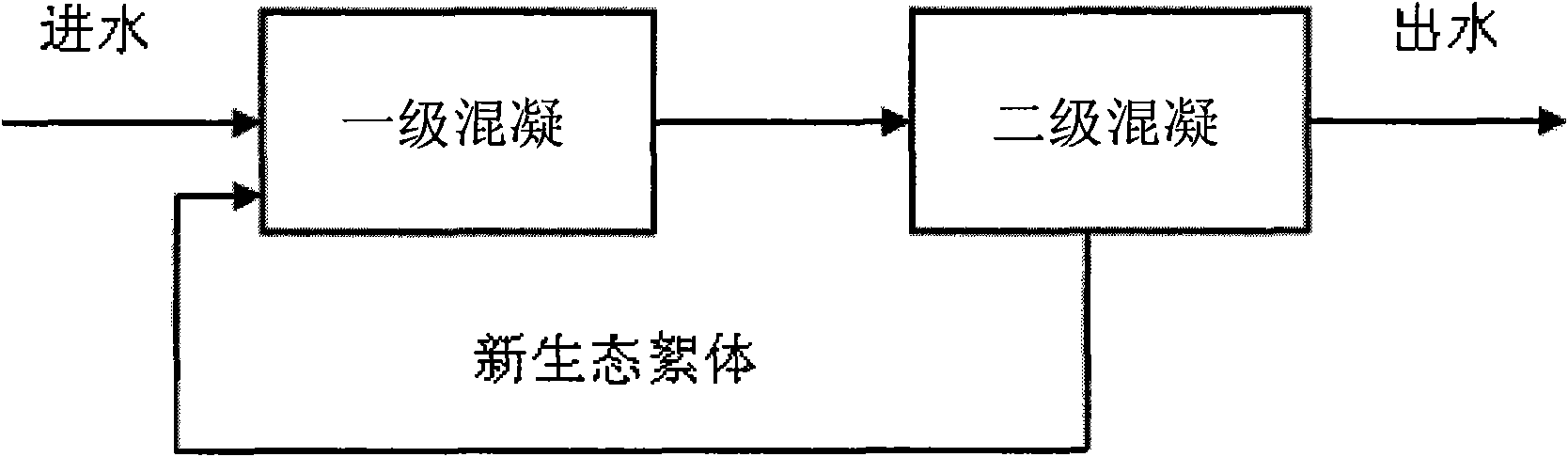

Two-stage sludge reflux enhanced coagulation technology

A sludge return and coagulation technology, applied in water/sludge/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems such as ineffectiveness, increased operating costs, and deterioration of effluent quality , to achieve the effect of enhanced impact load resistance, increased sedimentation speed, and less dosage of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Taking the simulated phosphorus-containing water as an example, the phosphorus concentration of the simulated phosphorus-containing water is 2.0 mg / L, and the pH is 7.5. Using aluminum-modified red mud as coagulant, a two-stage sludge return enhanced coagulation process is adopted, and the sludge return ratio is 15%. When the dosage of aluminum-modified red mud is 35mg / L (the primary dosage is 20mg / L, and the secondary dosage is 15mg / L), the phosphorus concentration in the effluent is 0.40mg / L, reaching the level of urban sewage treatment plant. A emission standard. With the traditional coagulation process, under the same dosage, the phosphorus concentration in the effluent is 0.60mg / L.

Embodiment 2

[0020] Taking the simulated phosphorus-containing water as an example, the phosphorus concentration of the simulated phosphorus-containing water is 2.0 mg / L, and the pH is 7.5. Ordinary polyaluminium chloride (PAC) was used as coagulant, and a two-stage sludge return enhanced coagulation process was adopted, with a sludge return ratio of 10%. When the dosage of PAC is 40mg / L (the primary dosage is 25mg / L, the secondary dosage is 15mg / L), the phosphorus concentration in the effluent is 0.40mg / L, which meets the first-class A discharge standard of urban sewage treatment plants. With the traditional coagulation process, under the same dosage, the phosphorus concentration in the effluent is 0.70mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com