Epitaxial Ti0.53Cr0.47N film material with low-temperature magneto-resistance effect, and preparation method thereof

A technology of epitaxial thin film and magnetoresistance, which is applied in the direction of coating with magnetic layer, metal material coating process, magnetic recording, etc., to achieve the effect of simple and practical method, simple target material selection and high target material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

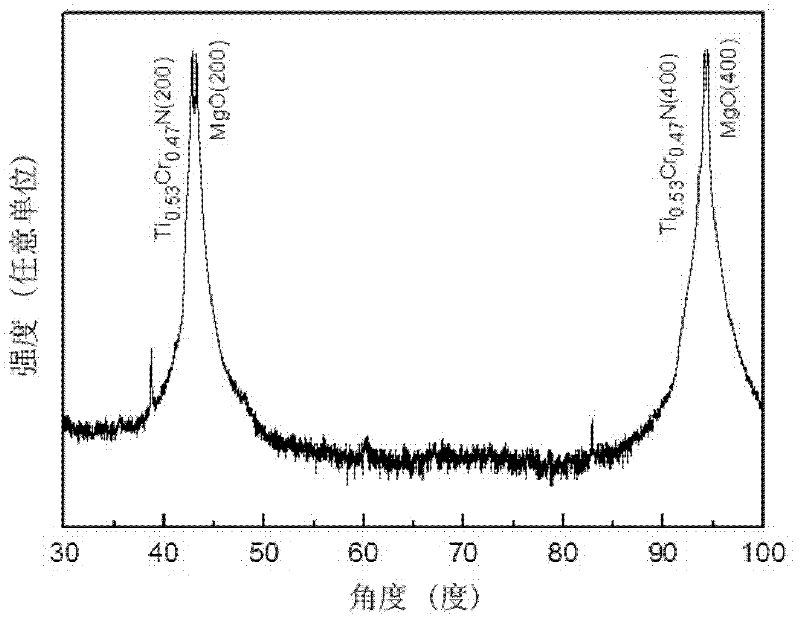

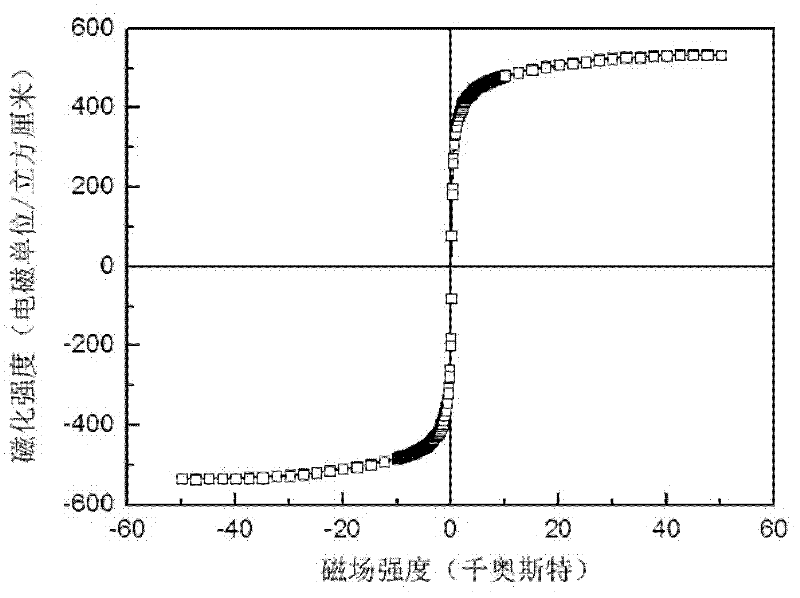

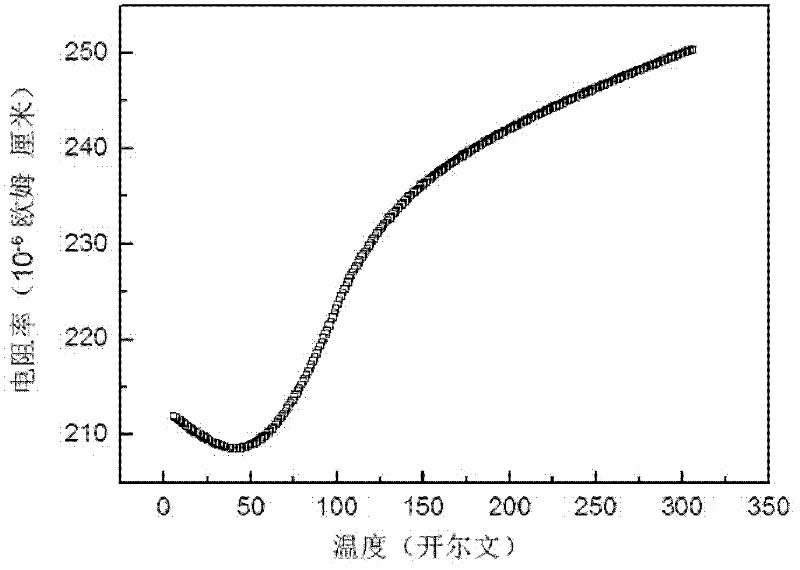

[0032] According to the structure and property analysis that we carry out to the sample prepared in the present invention, below will prepare Ti to target reactive sputtering method 0.53 Cr 0.47 The best implementation mode of N epitaxial thin film is described in detail:

[0033] 1. The DPS-III type ultra-high vacuum facing target magnetron sputtering coating machine produced by the Shenyang Scientific Instrument Development Center of the Chinese Academy of Sciences is adopted. The base material is MgO (100) single wafer, and a pair of purity is installed on the facing target head. For 99.99% Ti target, one end is used as the N pole of the magnetic force line, and the other end is the S pole; the thickness of the Ti target is 4mm, and the diameter is 60mm; in order to incorporate Cr, evenly place Cr sheets on the surface of the Ti target, and the area of the Cr sheets is 6mm 2 , the number of Cr sheets is 200, and the atomic percentage content of Cr relative to the sum of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com