Combustion nozzle for whole hydrogen bell-type annealing furnace, and waste hydrogen introduction and combustion method adopting the same

A technology of bell annealing furnace and combustion chamber, which is applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as non-compliance, waste of fuel resources, and influence of heating hood furnace temperature uniformity, so as to ensure reliability and ensure temperature Uniformity, the effect of ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with implementation examples and accompanying drawings, but the present invention is not limited.

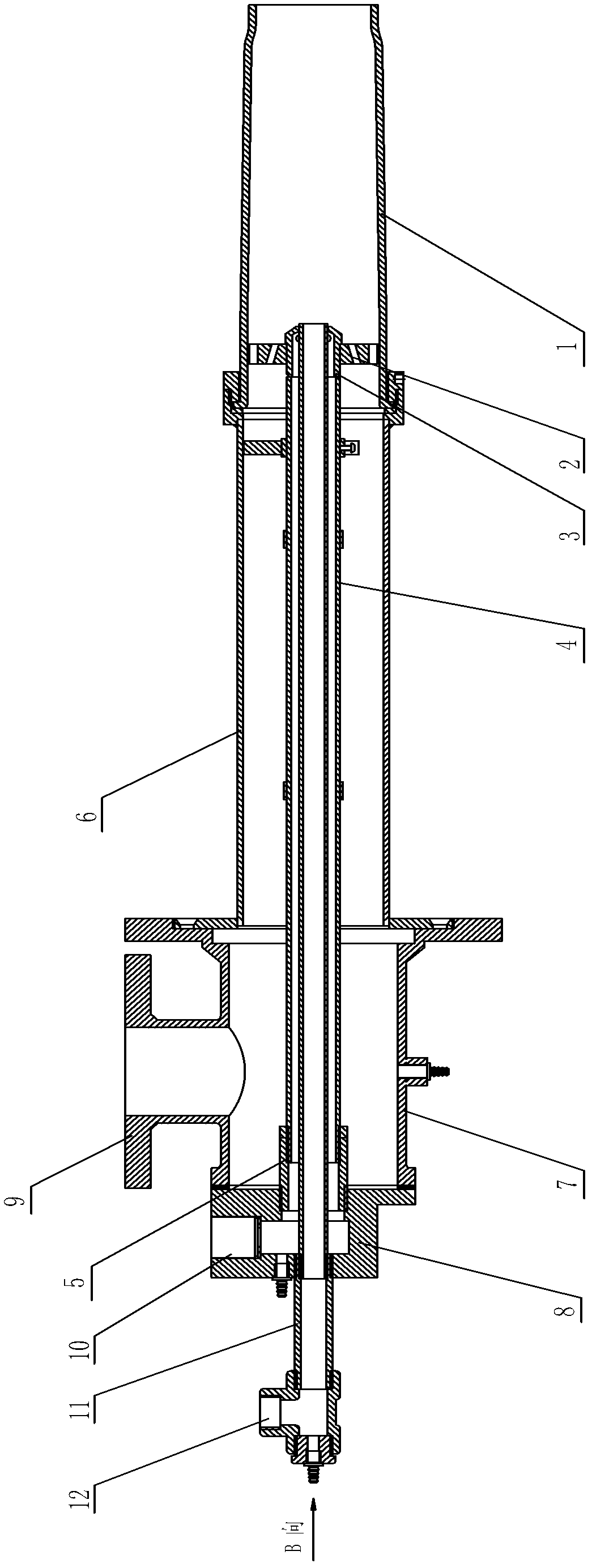

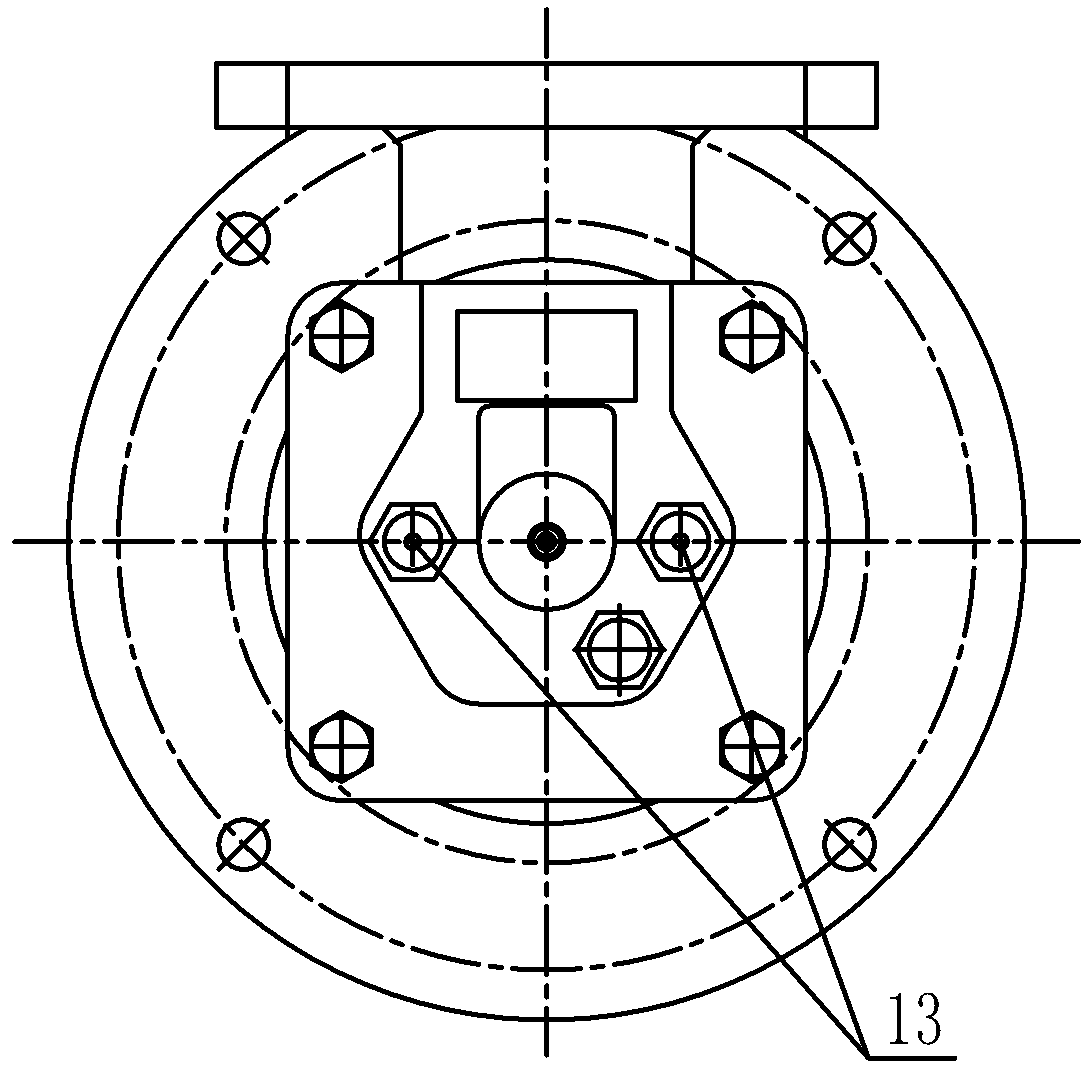

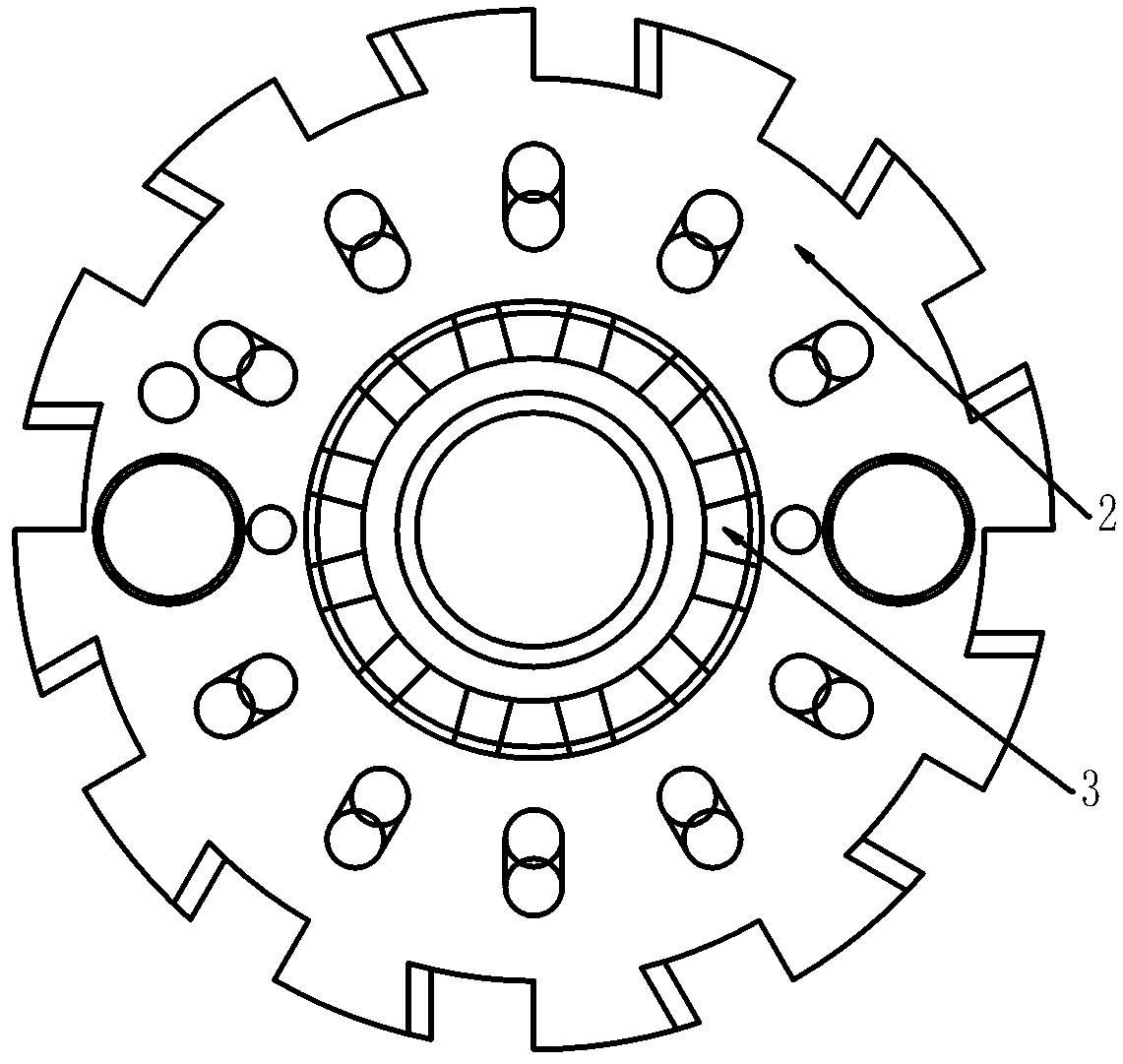

[0031] Figure 1-4 Shown is the internal structure of the burner for the full-hydrogen bell annealing furnace implemented according to the present invention, which includes a combustion chamber 1, which is a cylindrical cylinder placed horizontally, and the whole is casted and formed by SIC ceramics, and the temperature resistance level can reach 1400 °C, coal gas, waste hydrogen and air complete the mixing, ignition and combustion process in the combustion chamber 1. The diameter of the outlet end of the combustion chamber 1 is slightly contracted, and the inlet end is provided with a mounting plate. The diameter and length of the inlet and outlet of the combustion chamber 1 are determined according to the power of the burner and the amount of waste hydrogen that is designed to be burned. The air dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com