Solar heat collecting device

A solar heat collection and heat collection module technology, applied in the fields of energy and electric power, can solve the problems of loss of power generation efficiency, control signal lag heat energy, uneven heating of the heat collection device, etc., to overcome the control signal lag and solve the problem of uneven heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a solar thermal collector, comprising:

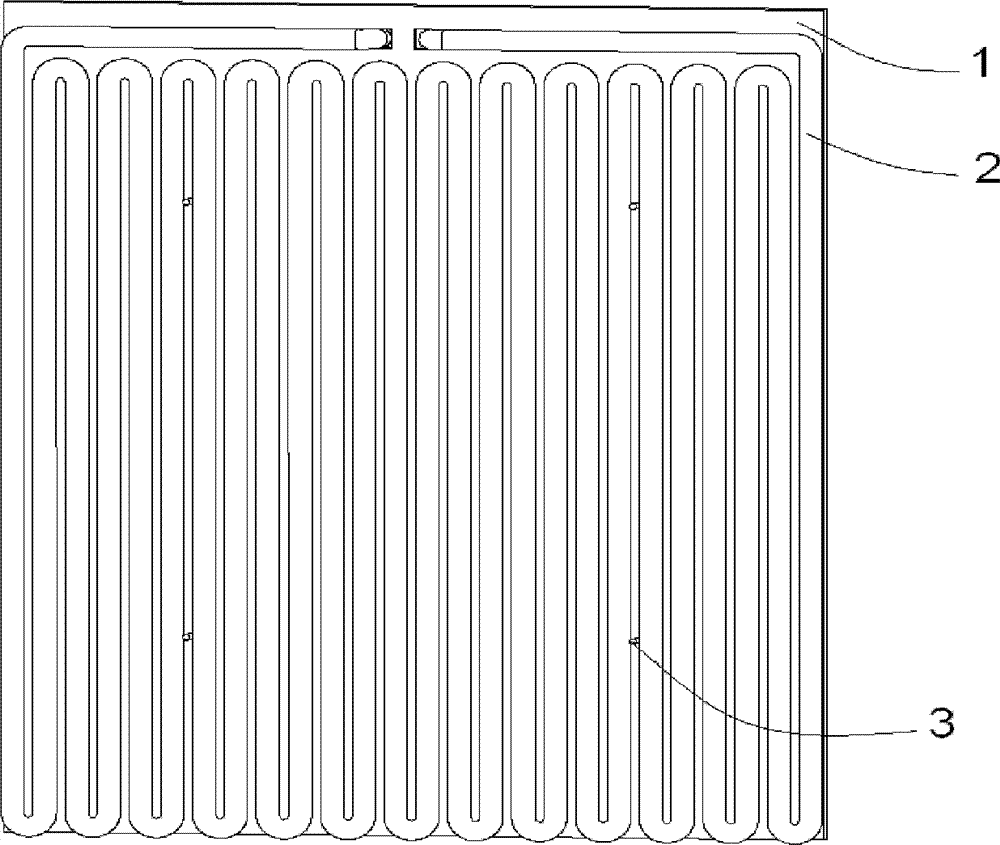

[0058] At least one heat collection module (11) is arranged between the inlet main pipe and the outlet main pipe, each of the heat collection modules (11) includes a hollow container with an inlet and an outlet, and a plurality of hollow containers are provided with suitable suction A pipeline through which the hot working medium flows, and a flow controller is arranged between the hollow container and the inlet main pipe and / or the outlet main pipe;

[0059] at least one driving pump, used to drive the heat-absorbing working fluid to flow into the hollow container;

[0060] It also includes a control system, controlling the flow controller to change the flow rate and / or flow rate of the heat-absorbing working fluid flowing into the hollow container;

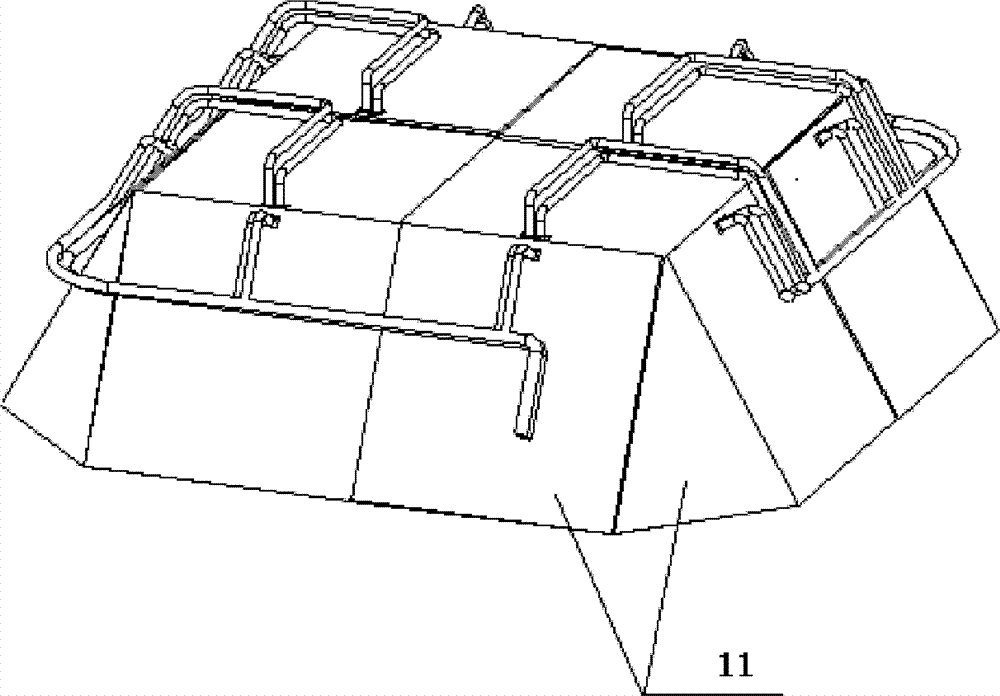

[0061] Such as image 3 As shown, at least one heat collection module 11 is assembled to form a polyhedron structure, and the polyhedron structure is arr...

Embodiment 2

[0068] In this embodiment, the control system further includes a computing unit;

[0069] The calculation unit is based on the feedforward adjustment signal output by the feedforward adjustment unit combined with the preset temperature value T at the outlet of the heat collection module 11 stored in the control unit 0 Or / and preset pressure value P 0 , generating an adjustment signal for adjusting the flow controller;

[0070] The control system adjusts the corresponding flow controller according to the adjustment signal of each flow controller, so as to change the flow rate and / or flow rate of the endothermic working medium flowing into the corresponding hollow container.

[0071] The outlet of the hollow container is provided with an outlet temperature sensor and / or a pressure sensor for measuring the temperature and / or pressure value at the outlet of the hollow container, and the outlet temperature sensor and / or pressure sensor and the control system inter-communication c...

Embodiment 3

[0080] In this embodiment, on the basis of embodiment 1 or embodiment 2, the flow regulator is selected as a valve and / or a flow-driven pump;

[0081] When the flow regulator is a valve, the control system controls the opening of the valve to change the flow rate and / or flow rate of the endothermic working medium flowing into the hollow container;

[0082] When the flow regulator is a flow-driven pump, the control system controls the rotation speed of the flow-driven pump to change the flow and / or flow rate of the heat-absorbing working medium flowing into the hollow container.

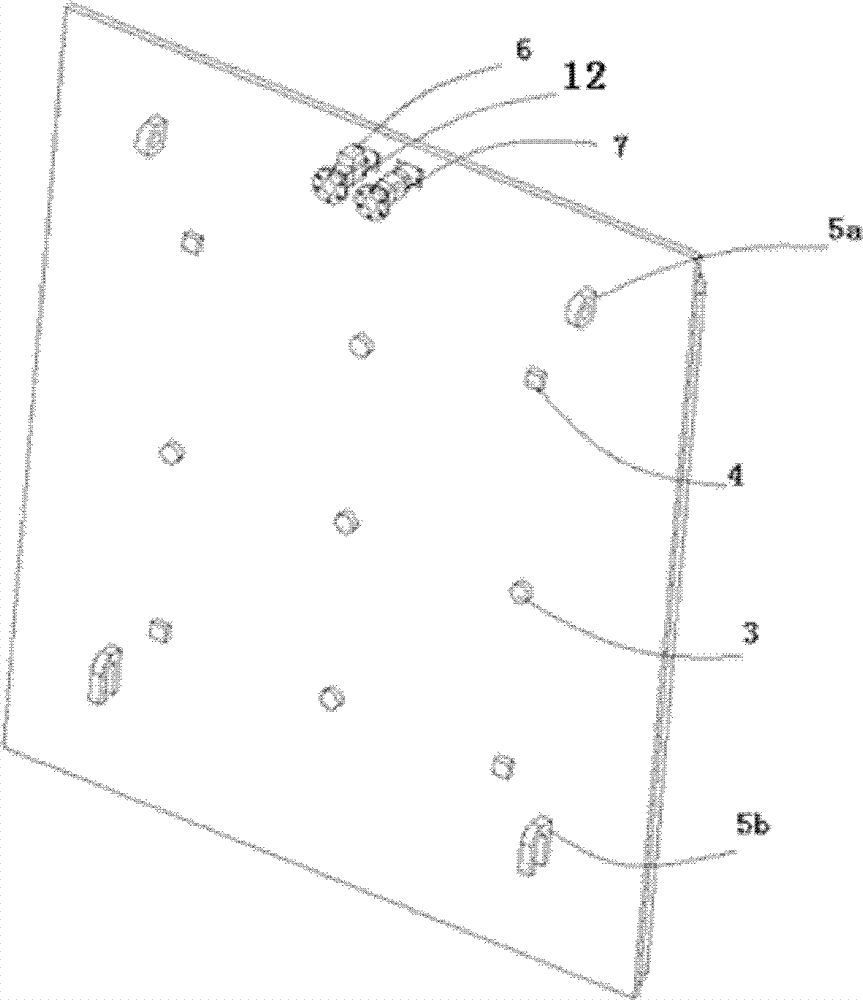

[0083] As a variable implementation of this embodiment, each heat collection module can be provided with an inlet valve 6 and an outlet valve 7 respectively. When the temperature and pressure of the endothermic working medium at the outlet valve of a certain heat collection module increase, the control system Control the inlet valve and outlet valve to increase the opening, accelerate the speed of heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com