High-precision method for measuring attitude angle of triaxial air bearing table and measurement device thereof

A technology of measuring device and air bearing table, which is applied in the space field, can solve the problems of complex mechanism and difficulty in achieving high precision, and achieve the effect of shortening the space distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

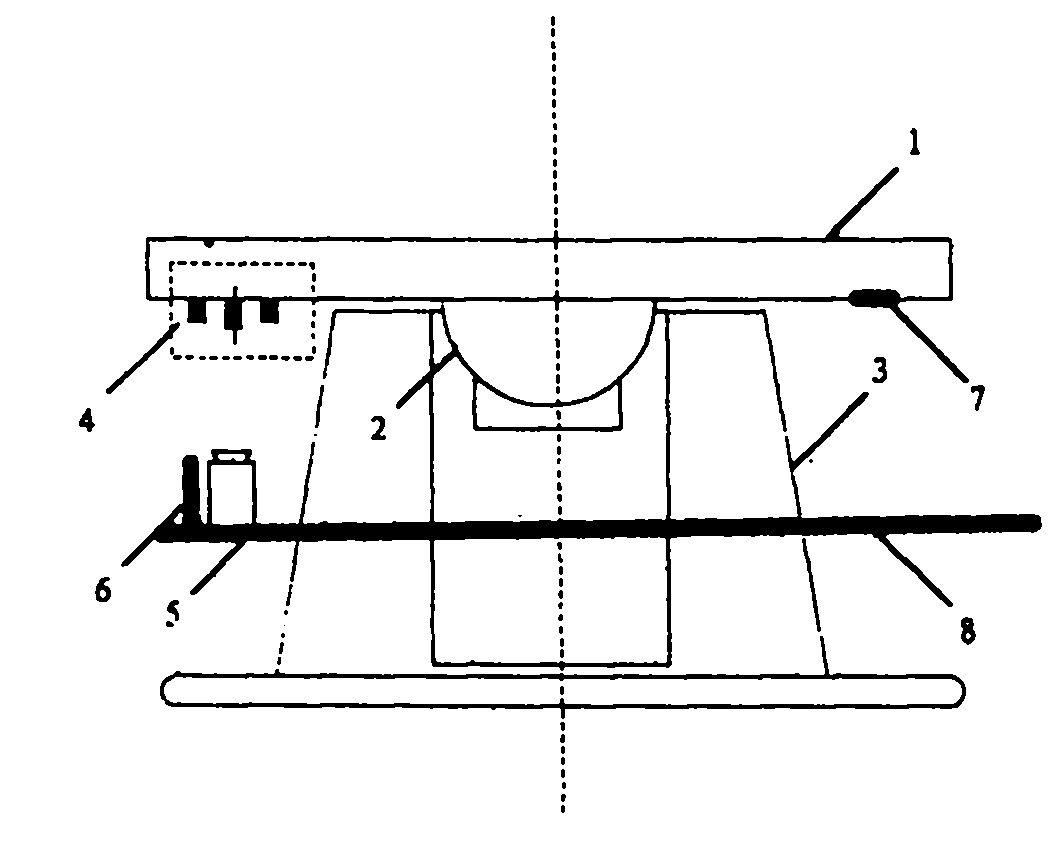

[0021] Example 1: Combining figure 1 , the present invention is a high-precision attitude angle measuring device for a three-axis air-floating table, which is composed of a three-axis air-floating table top (1), a three-axis air-floating table spherical air bearing (2), and a three-axis air-floating table bearing base seat (3), marker (4), digital CCD camera (5), artificial lighting system (6), blackout curtain, guide rail (7) and a liftable platform (8) for installing camera and artificial light source, Guide rails and shading curtains are installed around the bottom of the three-axis air flotation table (1), and the artificial lighting system is installed on the liftable platform. The visual measurement space of , the marker (4) is fixed on the bottom plane of the three-axis air bearing table (1), the angular movement of the two is exactly the same, and the liftable platform (8) for installing the camera and artificial light source is installed on the On the three-axis air ...

Embodiment 2

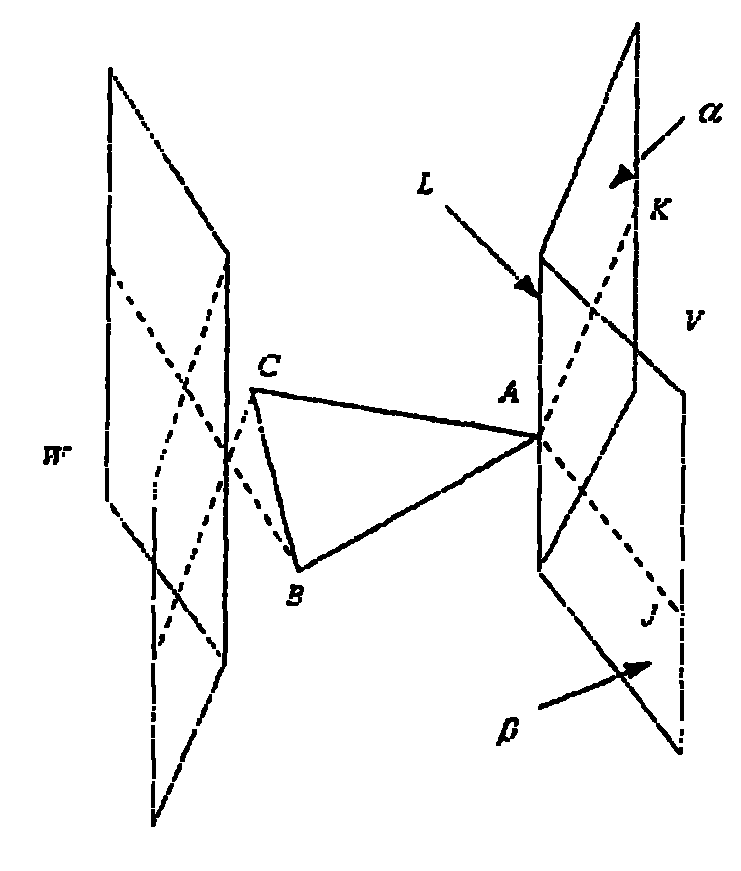

[0028] Example 2: Combining Figure 1-Figure 3 , the present invention mainly consists of the following parts: three-axis air-floation table top (1), three-axis air-floation table spherical surface air bearing (2), three-axis air-floation table bearing base (3), marker (4), A digital CCD camera (5), an artificial light source (6), a blackout curtain guide rail (7), a liftable platform (8) for installing the camera and the artificial light source. The marker (4) is fixed on the bottom plane of the three-axis air bearing table top (1), and the angular movement of the two is exactly the same. The liftable platform (8) is installed on the three-axis air bearing base (3), and can be moved up and down to a suitable position for fixing as required. The camera (5) is installed on the liftable platform (8) to collect image information of each mark on the marker (4), and the artificial light source (6) provides constant and reliable lighting for image collection. The camera is a black...

Embodiment 3

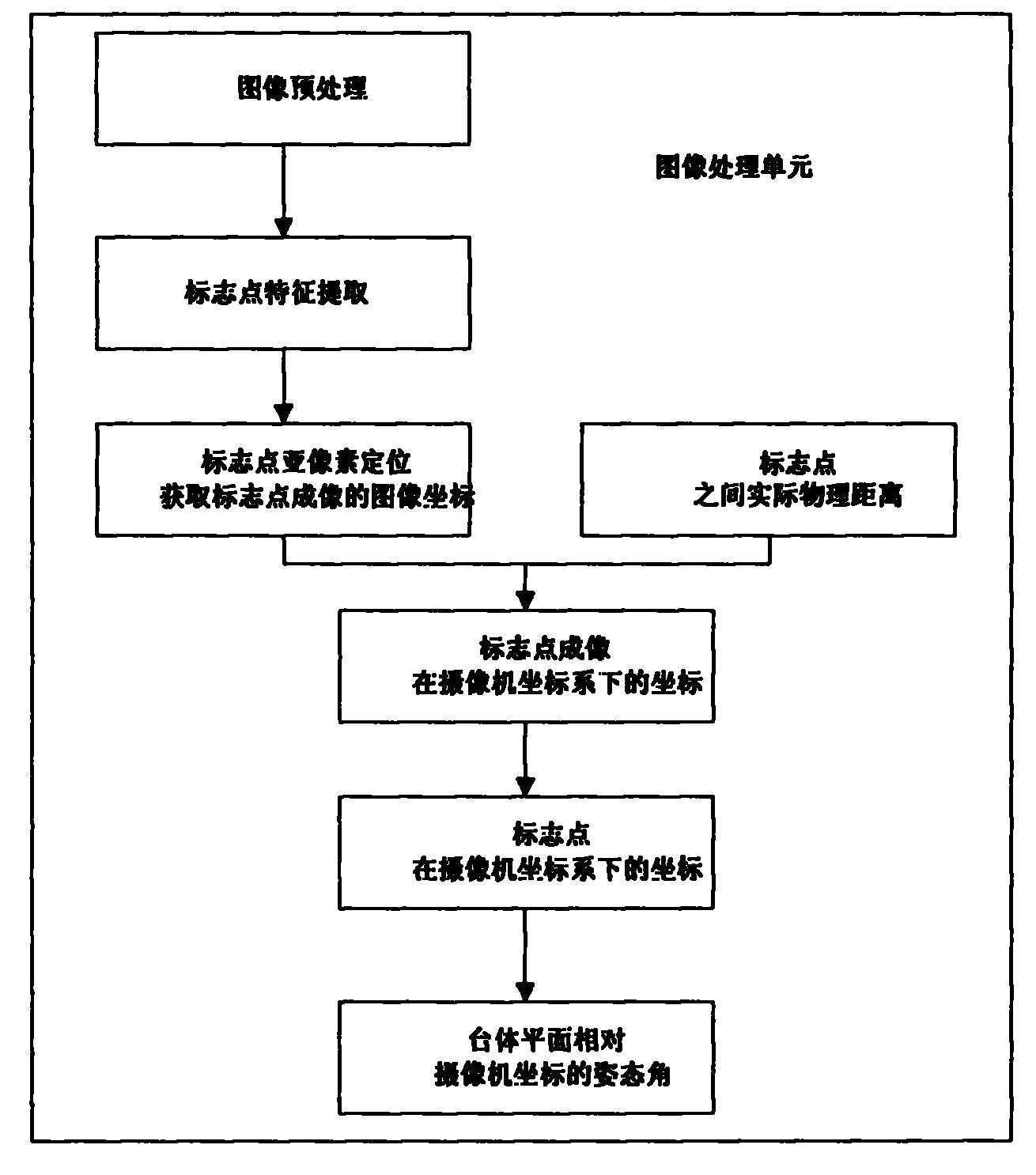

[0029] Embodiment 3: the basic work flow of the present invention is as image 3 As shown, the specific processing method is:

[0030] 1. Calibrate the camera: collect the image of the calibration board and use it as a calibration image to calibrate the camera. The number is more than 4; extract the calibration image and determine the image coordinates of each calibration point on the calibration board; according to the physical size of the calibration board, Determine the world coordinates of each calibration point on the calibration board; for the ideal central perspective imaging model of the camera, according to the above data, use the least square method to obtain the homography matrix H, which reflects the relationship between the world coordinate system and the image coordinate system; The corresponding matrix H can be solved to obtain the internal parameters of the camera, so as to obtain the parameters of the ideal perspective model of the camera; on the basis of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com