Gas concentration and sensing integrated device and preparation method thereof

A gas sensor and concentrator technology, applied in the field of integrated devices and preparation, can solve the problems of long thermal relaxation time of the acetone sensor and the gas concentrator, weakening the concentration effect of the gas concentrator, unable to integrate intelligent terminals, etc., so as to shorten the thermal relaxation time. The effect of hemp time, reduction of size and power consumption, and scientific preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The concrete steps of preparation are:

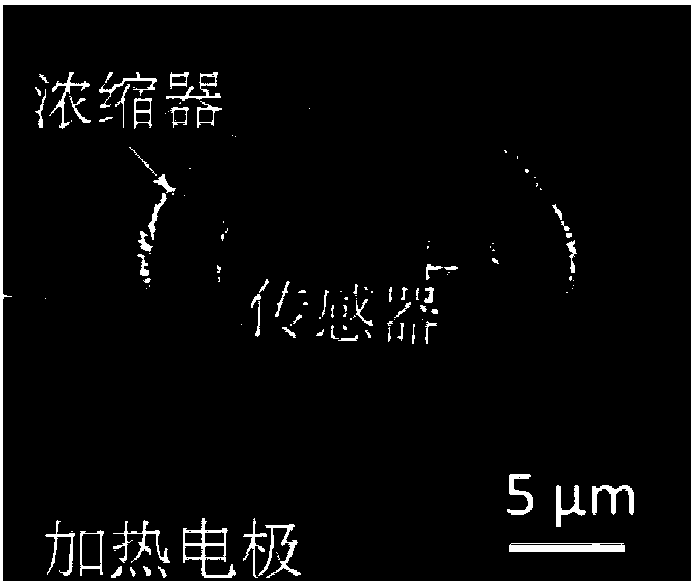

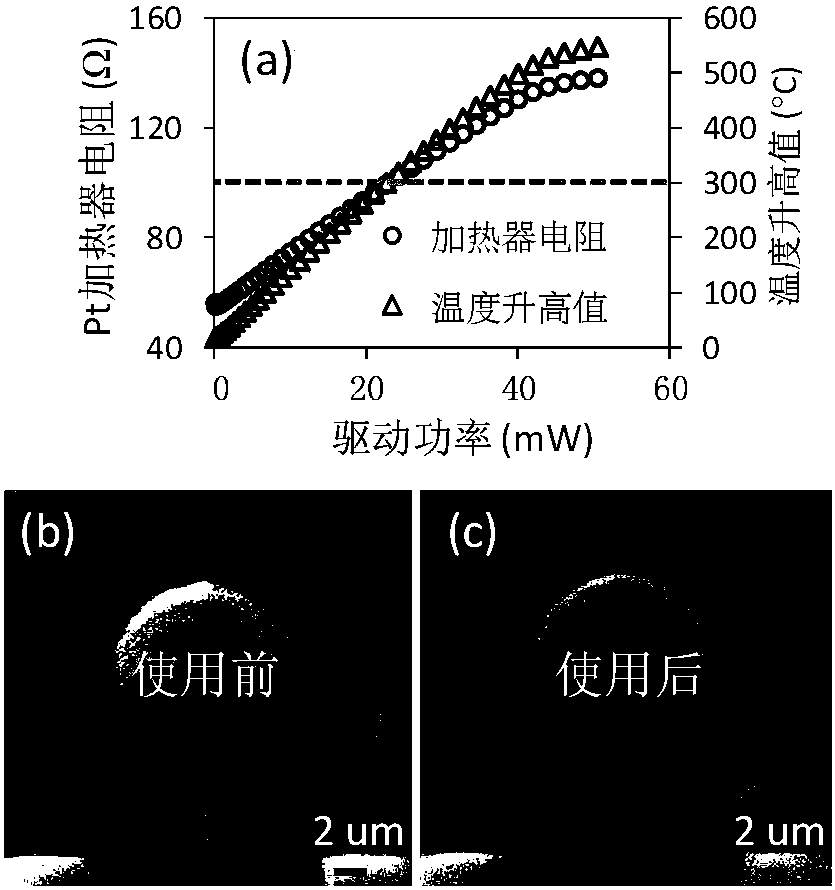

[0046] Step 1, after coating an electron beam resist on the silicon wafer covered with a mesoporous thermal insulation layer, a sensor pattern with a length of 3 μm and a width of 1.5 μm is drawn on it by an electron beam exposure method; wherein, The e-beam resist was ZEP 520A e-beam resist. After the metal oxide gas sensor is sputtered on the sensor pattern by magnetron sputtering, it is placed in dimethylformamide solution to peel off the electron beam resist to obtain the surface covered with the metal oxide gas sensor A silicon wafer covered with a mesoporous heat-insulating layer; wherein, the sputtering power of the metal oxide gas sensor is 80W and the sputtering time is 60min when using the magnetron sputtering method, and the thickness of the metal oxide gas sensor is 200nm. The metal oxide is tin dioxide.

[0047] Step 2, after the electron beam resist is coated on the silicon wafer covered with the mesoporous heat i...

Embodiment 2

[0052] The concrete steps of preparation are:

[0053] Step 1, after coating an electron beam resist on the silicon wafer covered with a mesoporous thermal insulation layer, a sensor pattern with a length of 3.5 μm and a width of 1.2 μm is drawn on it by an electron beam exposure method; , the electron beam resist is ZEP 520A electron beam resist. After the metal oxide gas sensor is sputtered on the sensor pattern by magnetron sputtering, it is placed in dimethylformamide solution to peel off the electron beam resist to obtain the surface covered with the metal oxide gas sensor A silicon wafer covered with a mesoporous heat-insulating layer; wherein, the sputtering power of the metal oxide gas sensor is 90W, the sputtering time is 48min, and the thickness of the metal oxide gas sensor is 175nm when using the magnetron sputtering method. The metal oxide is tin dioxide.

[0054] Step 2, after the electron beam resist is coated on the silicon wafer covered with the mesoporous h...

Embodiment 3

[0059] The concrete steps of preparation are:

[0060] Step 1, after coating an electron beam resist on the silicon wafer covered with a mesoporous thermal insulation layer, a sensor pattern with a length of 4 μm and a width of 0.9 μm is drawn on it by an electron beam exposure method; wherein, The e-beam resist was ZEP 520A e-beam resist. After the metal oxide gas sensor is sputtered on the sensor pattern by magnetron sputtering, it is placed in dimethylformamide solution to peel off the electron beam resist to obtain the surface covered with the metal oxide gas sensor A silicon wafer covered with a mesoporous heat-insulating layer; wherein, the sputtering power of the metal oxide gas sensor is 100W and the sputtering time is 35min when using the magnetron sputtering method, and the thickness of the metal oxide gas sensor is 150nm. The metal oxide is tin dioxide.

[0061] Step 2, after the electron beam resist is coated on the silicon wafer covered with the mesoporous heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com